High-Quality and Efficient PCB Prototype Factory for Your Manufacturing Needs

By:Admin

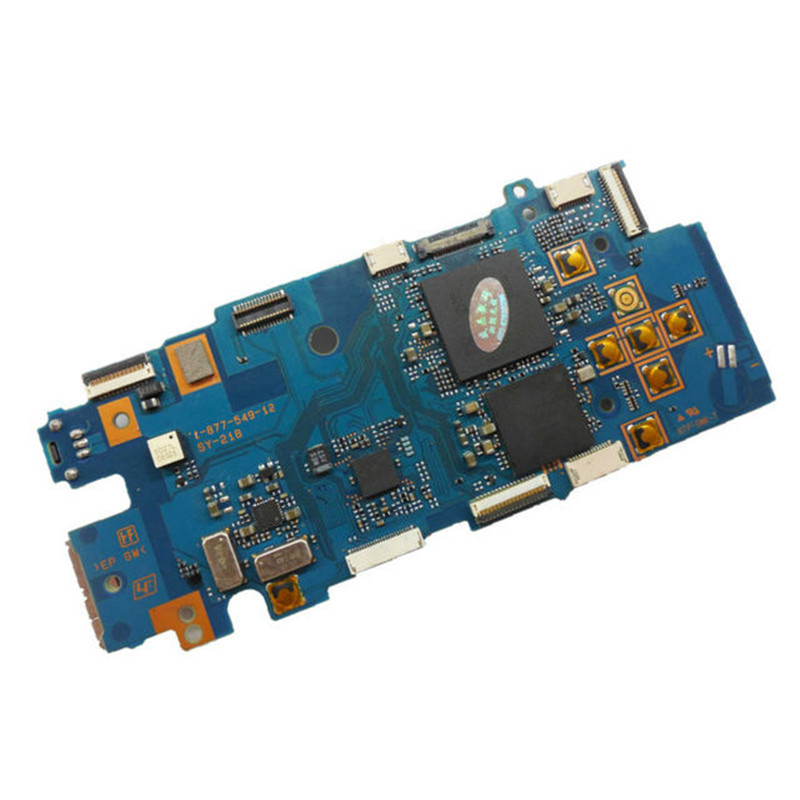

With a state-of-the-art facility and a team of experienced engineers and technicians, Pcb Prototype Factory is committed to providing top-notch PCB prototypes and assembly services to a wide range of industries, including aerospace, telecommunications, automotive, and consumer electronics.

The company's unwavering focus on innovation and customer satisfaction has earned them a solid reputation in the market. Pcb Prototype Factory's advanced capabilities allow them to produce complex PCB prototypes with quick turnaround times, enabling their clients to stay ahead of the competition in today's fast-paced business environment.

In addition to their advanced production technology, Pcb Prototype Factory also emphasizes the importance of quality control and testing. Each PCB prototype undergoes rigorous inspection and testing processes to ensure its reliability and performance. This dedication to quality has made Pcb Prototype Factory a trusted partner for many businesses looking for reliable PCB solutions.

Furthermore, Pcb Prototype Factory takes pride in its commitment to sustainable and environmentally-friendly manufacturing practices. The company has implemented various measures to minimize its environmental impact, such as using eco-friendly materials and optimizing production processes to reduce waste.

In a recent statement, the CEO of Pcb Prototype Factory expressed the company's continual dedication to innovation and high standards in the PCB industry. "We are dedicated to providing our clients with superior PCB prototypes that meet their exact specifications and exceed their expectations. Our team is constantly pushing the boundaries of technology to deliver cutting-edge solutions that empower our clients to thrive in their respective industries," said the CEO.

As part of their commitment to excellence, Pcb Prototype Factory is also investing in research and development to stay at the forefront of emerging technologies and industry trends. By staying informed of the latest advancements, the company can offer innovative solutions that meet the evolving needs of their clients.

Another key aspect of Pcb Prototype Factory's success is their exceptional customer service. The company prides itself on maintaining strong relationships with clients, offering personalized support, and ensuring clear communication throughout the production process. This customer-centric approach has allowed Pcb Prototype Factory to build long-term partnerships with many of its clients, who value the company's reliability, expertise, and dedication to their success.

Looking ahead, Pcb Prototype Factory remains committed to driving innovation and setting new industry standards for PCB prototypes and assembly services. With a strong foundation in advanced technology, quality control, sustainability, and customer service, the company is well-positioned to continue its growth and success in the PCB manufacturing industry.

In conclusion, Pcb Prototype Factory's commitment to excellence, innovation, and customer satisfaction sets them apart as a leader in the PCB industry. As they continue to invest in cutting-edge technology, quality control, and sustainable practices, Pcb Prototype Factory is poised to remain at the forefront of the industry and meet the evolving needs of their clients for years to come.

Company News & Blog

Understanding the SMT Assembly Process in Factories

Smt Assembly Process Factories, a leading global electronics manufacturing company with a focus on high-quality, precision electronic components and assemblies, has continued to expand its operations and capabilities in response to the increasing demand for advanced electronics across various industries.The company has been at the forefront of providing innovative solutions for the assembly and manufacturing of surface mount technology (SMT) products. SMT is a key process in electronics manufacturing, as it allows for the creation of smaller, lighter, and more efficient electronic devices. With the increasing focus on miniaturization and the integration of advanced functionalities into electronic products, the demand for SMT assembly services has been on the rise.Smt Assembly Process Factories has established itself as a reliable and trusted partner for companies in need of high-quality SMT assembly services. The company offers a wide range of capabilities, including SMT assembly, through-hole assembly, box build assembly, and testing services. This comprehensive range of services has enabled Smt Assembly Process Factories to cater to the diverse needs of its customers, from small startups to large corporations.In addition to its advanced assembly capabilities, Smt Assembly Process Factories has also invested in state-of-the-art equipment and manufacturing facilities to ensure the highest level of precision and quality control. The company's commitment to quality is evident in its adherence to strict manufacturing standards and its implementation of industry-leading quality management systems.One of the key strengths of Smt Assembly Process Factories is its focus on innovation and continuous improvement. The company's dedicated team of engineers and technical experts are constantly exploring new technologies and processes to enhance the efficiency and capabilities of its assembly operations. This commitment to innovation has allowed Smt Assembly Process Factories to stay ahead of the competition and provide its customers with cutting-edge solutions.As part of its expansion efforts, Smt Assembly Process Factories has recently announced the opening of a new manufacturing facility in a strategic location to better serve its global customer base. This new facility is equipped with the latest SMT assembly equipment and is designed to meet the growing demand for high-volume production of electronic components and assemblies.Furthermore, Smt Assembly Process Factories has also expanded its workforce to include a team of highly skilled and experienced professionals who are dedicated to delivering exceptional service and support to customers. The company's workforce consists of individuals with diverse backgrounds and expertise, including engineers, technicians, quality control specialists, and customer service personnel.With its strong focus on quality, innovation, and customer satisfaction, Smt Assembly Process Factories is well-positioned to address the evolving needs of the electronics manufacturing industry. The company's commitment to delivering high-quality products and services has earned it a reputation as a preferred partner for businesses seeking reliable and cost-effective SMT assembly solutions.As the demand for advanced electronics continues to grow, Smt Assembly Process Factories remains committed to staying at the forefront of technological advancements and delivering value-added solutions to its customers. The company's dedication to excellence and its ability to adapt to the changing industry landscape make it a key player in the global electronics manufacturing sector.

Top Medical PCB Assembly Suppliers: A In-Depth Look

Medical PCB Assembly Suppliers and [Company Name]'s Expertise in Meeting the Demands of Medical Device IndustryIn today's fast-paced world, the demand for advanced medical devices and equipment is constantly on the rise. As a result, medical PCB assembly suppliers play a crucial role in the development and production of these devices. [Company Name] is a leading PCB assembly supplier that specializes in meeting the specific needs of the medical device industry, offering top-quality, reliable, and efficient solutions for the production of medical electronics.[Company Name] has a long-standing reputation for excellence and innovation in the field of PCB assembly. With a commitment to quality, precision, and customer satisfaction, the company has established itself as a trusted partner for medical device manufacturers. By leveraging cutting-edge technology and industry expertise, [Company Name] is able to provide customized PCB assembly solutions that meet the stringent requirements of the medical device industry.The medical device industry has unique and demanding specifications that require precision and reliability in PCB assembly. [Company Name] understands these requirements and has developed an extensive portfolio of services and capabilities to address these specific needs. From prototype development to full-scale production, the company offers a comprehensive range of PCB assembly services that are tailored to the stringent regulatory and quality standards of the medical device industry.The company's state-of-the-art manufacturing facilities are equipped with advanced machinery and equipment, allowing for the efficient production of high-quality PCB assemblies. [Company Name]'s team of skilled engineers and technicians are experienced in working with medical device manufacturers to develop and manufacture PCB assemblies that meet the highest standards of quality and performance.In addition to its manufacturing capabilities, [Company Name] also places a strong emphasis on quality control and testing. The company follows strict quality assurance protocols throughout the production process to ensure that every PCB assembly meets the specific requirements of the medical device industry. [Company Name] is also ISO 13485 certified, demonstrating its commitment to maintaining the highest levels of quality and safety in its products and services.As a leading medical PCB assembly supplier, [Company Name] is dedicated to staying at the forefront of technological advancements in the industry. The company invests in ongoing research and development to continuously enhance its capabilities and to meet the evolving demands of the medical device market. By staying ahead of industry trends and innovations, [Company Name] is able to offer its customers the most advanced and reliable PCB assembly solutions available.The company's dedication to innovation and excellence has positioned it as a preferred partner for medical device manufacturers seeking reliable and high-quality PCB assembly services. With a proven track record of delivering top-notch products and services, [Company Name] has built strong relationships with clients in the medical device industry, earning a reputation for outstanding customer satisfaction and reliability.In conclusion, [Company Name] is a leading medical PCB assembly supplier that excels in meeting the unique and demanding requirements of the medical device industry. With a focus on quality, precision, and innovation, the company is committed to providing top-quality, reliable, and efficient PCB assembly solutions for medical electronics. By continuing to invest in advanced technology, quality control, and research and development, [Company Name] is well-positioned to remain a trusted partner for medical device manufacturers seeking superior PCB assembly services.

Top Factories for Pin Through Hole Manufacturing: A Comprehensive Guide

Pin Through Hole Factories, a leading manufacturer of electronic components, has announced the expansion of its production facilities in order to meet the increasing demand for its products. With the global electronics market on the rise, the company is ramping up its manufacturing capabilities in order to ensure a steady supply of high-quality components to its customers. This expansion comes as part of Pin Through Hole Factories' commitment to providing innovative and reliable solutions to the electronics industry.The company, founded in 1995, has built a reputation for excellence in the production of pin through hole components. With a focus on quality, reliability, and customer satisfaction, Pin Through Hole Factories has become a trusted partner for electronic manufacturers worldwide. The company's dedication to continuous improvement and innovation has allowed it to stay ahead of the curve in a competitive industry. The expansion of its production facilities is a strategic move to position Pin Through Hole Factories for future growth and success. By increasing its manufacturing capacity, the company aims to better serve its customers and strengthen its position as a leading supplier of electronic components. The new facilities will feature state-of-the-art equipment and technology, allowing Pin Through Hole Factories to enhance its production capabilities and maintain its high standards of quality.In addition to the expansion of its production facilities, Pin Through Hole Factories is also investing in research and development to drive innovation in the design and manufacturing of electronic components. The company understands the importance of staying at the forefront of technological advancements in order to meet the evolving needs of its customers. By investing in R&D, Pin Through Hole Factories is committed to developing new and improved products that will set the standard for the industry.The expansion of Pin Through Hole Factories' production facilities is expected to create new job opportunities and contribute to the local economy. As the company grows, it will continue to support the community by providing employment and driving economic development. Pin Through Hole Factories understands the importance of giving back to the community and is dedicated to being a responsible corporate citizen.The expansion of Pin Through Hole Factories' production facilities is a testament to the company's commitment to meeting the growing demand for its products and providing exceptional service to its customers. By investing in state-of-the-art manufacturing capabilities and driving innovation through research and development, Pin Through Hole Factories is positioning itself for long-term success in the dynamic electronics industry.As the global electronics market continues to expand, Pin Through Hole Factories is poised to play a key role in supplying the components that power the latest technological innovations. With its dedication to quality, innovation, and customer satisfaction, Pin Through Hole Factories is well-positioned for continued growth and success in the years to come. The company's expansion of its production facilities is a clear indication of its commitment to meeting the needs of the electronics industry and its customers.

Top Assembler Manufacturer - Find the Best Manufacturer for your Needs

Smt Assembler Manufacturer to Expand Production Capacity to Meet Growing DemandAs the demand for electronics continues to grow, Smt Assembler Manufacturer (SAM) has announced plans to expand its production capacity to keep up with the increasing market needs. With its commitment to providing high-quality surface mount technology (SMT) assembly solutions, the company is taking proactive steps to ensure it can meet the needs of its customers, both now and in the future.Founded in 1995, SAM has established itself as a leading manufacturer of SMT assembly equipment, catering to a wide range of industries including automotive, aerospace, telecommunications, and consumer electronics. The company is known for its innovative technology, reliable products, and exceptional customer service, making it a trusted partner for businesses seeking high-performance SMT assembly solutions.The decision to expand production capacity comes as SAM continues to experience a surge in demand for its products. With the rapid advancement in technology and the increasing complexity of electronic components, the need for reliable and efficient SMT assembly equipment has never been greater. By expanding its production capacity, SAM aims to strengthen its position in the market and reinforce its commitment to meeting the evolving needs of its customers.The expansion plans include the addition of new manufacturing facilities, the installation of advanced production equipment, and the hiring of additional skilled workforce. By leveraging the latest technology and optimizing its production processes, SAM is confident that it can significantly increase its output and improve its overall operational efficiency. Additionally, the company plans to streamline its supply chain management to ensure a seamless transition during the expansion phase.In a statement, the CEO of SAM expressed enthusiasm about the expansion plans, stating, "This is an exciting time for our company as we embark on this expansion journey. With the growing demand for SMT assembly solutions, we are committed to scaling our production capacity to better serve our customers. By investing in state-of-the-art facilities and equipment, we are positioning ourselves for sustained growth and success in the years to come."The expansion is expected to have a positive impact on the local economy, creating new job opportunities and fostering growth in the manufacturing sector. As SAM continues to expand its operations, it is also exploring opportunities to further integrate sustainable and environmentally friendly practices into its manufacturing processes, aligning with its commitment to corporate social responsibility.The company is confident that the expansion will enable it to maintain its reputation for delivering high-quality SMT assembly solutions while also catering to the increasing demand for its products. By leveraging its expertise, innovation, and dedication to customer satisfaction, SAM is poised to emerge as a dominant player in the global SMT assembly market.As SAM moves forward with its expansion plans, it remains steadfast in its mission to be a trusted partner for businesses seeking reliable and efficient SMT assembly solutions. With a focus on continuous improvement and customer-centric innovation, the company is well-positioned to meet the ever-evolving needs of the electronics industry and deliver value to its customers worldwide.

Expert Guide to Pcb Assembly At Home: Everything You Need to Know

In recent years, there has been a growing trend in the electronics industry towards home-based PCB assembly. With the advancement of technology and the availability of DIY kits, individuals are now able to assemble their own PCBs from the comfort of their homes. This trend has been further fueled by the increasing demand for custom electronic projects and prototypes, as well as the desire for more control and flexibility in the assembly process.One company at the forefront of this movement is {}. With a long history of providing high-quality PCB assembly services to a wide range of industries, they have now expanded their offerings to include a line of products specifically designed for home-based assembly. These products include DIY assembly kits, step-by-step instructions, and all the necessary components to help individuals create their own electronic devices at home.The shift towards home-based PCB assembly has opened up a world of possibilities for electronics enthusiasts, hobbyists, and small businesses. It allows them to take their ideas from concept to reality without the need for expensive equipment or specialized knowledge. This democratization of the assembly process has empowered individuals to explore their creativity and bring their innovative ideas to life.Additionally, home-based assembly offers numerous benefits such as cost savings, convenience, and the ability to work at one's own pace. This can be particularly advantageous for small businesses and startups looking to reduce their overhead costs and speed up the prototyping process. It also provides individuals with a greater sense of ownership and satisfaction, knowing that they have personally assembled their electronic devices from start to finish.Furthermore, home-based assembly is environmentally friendly as it reduces the need for mass production and the associated waste. By allowing individuals to only produce the quantity they need, it helps to minimize excess inventory and resources. This aligns with the growing consumer demand for sustainable and eco-friendly products, making home-based PCB assembly a win-win for both individuals and the environment.{Company} is committed to supporting this growing trend by providing comprehensive resources and support for home-based PCB assembly. They have developed a user-friendly platform that guides individuals through the entire assembly process, from choosing the right components to soldering and testing the final product. Additionally, their team of experts is readily available to offer guidance and technical support to ensure a smooth and successful assembly experience.In conclusion, the rise of home-based PCB assembly represents a significant shift in the electronics industry. It has empowered individuals to take control of the assembly process, fostering creativity, cost savings, and environmental sustainability. With the support of companies like {}, home-based assembly is expected to continue growing and shaping the future of electronics manufacturing.

Streamlined Box Build Services for Efficient Project Execution - A Comprehensive Analysis

[Headline]: Leading Turnkey Box Build Provider Advances Manufacturing Capabilities[Subheadline]: Industry Expertises to Cater to Growing Demand for Turnkey Solutions[Date][City, State] - The global turnkey box build industry is set to witness a significant boost in manufacturing capabilities as a leading provider, [Company Name], bolsters its expertise in delivering turnkey solutions. With an unwavering commitment to excellence, [Company Name] is poised to cater to the increasing demand for box build services across various sectors, including automotive, telecommunications, and consumer electronics.Established with a vision to streamline the manufacturing process, [Company Name] has emerged as a frontrunner in providing holistic turnkey solutions. By leveraging cutting-edge technologies and a team of skilled professionals, the company has amassed a notable reputation for delivering high-quality, reliable, and efficient box build solutions.With an extensive history dating back over [XX] years, [Company Name] has continually adapted to market needs. The company's relentless pursuit of innovation has allowed it to stay ahead in an ever-evolving industry landscape. As a result, [Company Name] currently operates state-of-the-art manufacturing facilities across [number of locations] worldwide, strategically positioned to meet the demands of its global clientele.[Company Name's] comprehensive turnkey box build solutions encompass all stages of the manufacturing process, from design and prototyping to final assembly and testing. By serving as a single point of contact, the company ensures seamless coordination between various suppliers, enabling its clients to focus on their core competencies. Moreover, the unified approach significantly reduces lead times, minimizes costs, and eliminates the need for multiple vendors, making [Company Name] an invaluable partner to businesses across industries.Anchored by a customer-centric philosophy and a commitment to exceeding expectations, [Company Name] places great emphasis on fostering strong partnerships. By working closely with clients, the company ensures a deep understanding of their unique requirements, allowing it to tailor and deliver customized turnkey solutions. Beyond manufacturing capabilities, [Company Name] provides advisory services, assisting clients in achieving optimized designs, improved efficiencies, and enhanced product quality.The automotive industry, in particular, stands to benefit from [Company Name's] expanded manufacturing capabilities. As the sector accelerates its transition towards electric and autonomous vehicles, the demand for reliable turnkey solutions has become crucial. [Company Name], with its extensive experience in serving the automotive market, is well-positioned to cater to this shifting landscape. By providing turnkey box build services encompassing advanced electronics, wiring harnesses, and complex assemblies, [Company Name] enables automotive manufacturers to streamline production and meet the demands of tomorrow's vehicles.In the rapidly expanding telecommunications sector, [Company Name] plays a vital role in supporting the deployment of advanced network infrastructure. With the rise of 5G technology and increasing demand for data connectivity, telecom companies require agile and efficient manufacturing solutions. By offering turnkey box build services for telecom equipment, [Company Name] assists in accelerating the deployment of network infrastructure, ensuring seamless connectivity for consumers and businesses alike.The consumer electronics industry, driven by constant technological advancements, necessitates a reliable and versatile turnkey solution provider. [Company Name]'s expertise in manufacturing complex electronic assemblies and products allows it to meet the needs of this dynamic industry. From smartphones to IoT devices, [Company Name] delivers comprehensive turnkey box build services, encompassing component sourcing, PCB assembly, and final integration. By offering end-to-end solutions, [Company Name] enables consumer electronics manufacturers to bring innovative products to market swiftly and cost-effectively.With an unwavering commitment to quality, prompt delivery, and customer satisfaction, [Company Name] is set to revolutionize the turnkey box build industry. As technology continues to evolve, the company's advanced manufacturing capabilities position it as a reliable partner for businesses seeking streamlined and efficient production solutions. By embracing innovation and remaining dedicated to client success, [Company Name] solidifies its position as a leading turnkey box build provider in a rapidly changing world.About [Company Name]:[Company Name] is a global leader in turnkey box build solutions, serving various industries, including automotive, telecommunications, and consumer electronics. With cutting-edge technologies, state-of-the-art manufacturing facilities, and a commitment to excellence, [Company Name] offers comprehensive turnkey solutions, covering all stages of the manufacturing process. From design to final assembly and testing, [Company Name] acts as a single point of contact, providing streamlined coordination and customized solutions. Backed by decades of experience, [Company Name] is revolutionizing the box build industry through its advanced manufacturing capabilities and unwavering dedication to client success.For more information, please visit [Company Website].Press Contact:[Media Contact Name][Company Name][Phone Number][Email Address]

Top Quality PCB Assembly Factory for Main Assembly Components

Main PCB Assembly Factory Celebrates 20 Years of Innovation and Excellence[City], [Date] – [Main PCB Assembly Factory] is proud to announce its 20th anniversary as a leading provider of comprehensive PCB assembly solutions for a wide range of industries. Since its inception in [year], the company has been dedicated to delivering high-quality products and exceptional customer service, earning a reputation as a trusted and reliable partner in the electronics manufacturing industry.With state-of-the-art facilities and a team of experienced professionals, [Main PCB Assembly Factory] has continuously innovated and adapted to meet the evolving needs of its clients. The company offers a complete range of services, including PCB assembly, surface mount technology (SMT), through-hole assembly, testing, and packaging. Whether it’s a prototype, low volume, or high volume production, [Main PCB Assembly Factory] has the capabilities to handle projects of any size and complexity.One of the key factors behind the success of [Main PCB Assembly Factory] is its commitment to investing in the latest technology and equipment. The company’s manufacturing facilities are equipped with advanced machinery and tools, allowing for precision and efficiency in the assembly process. Additionally, [Main PCB Assembly Factory] adheres to strict quality control measures to ensure that all products meet the highest standards of performance and reliability.Another crucial aspect of [Main PCB Assembly Factory]’s success is its focus on customer satisfaction. The company takes a collaborative approach with its clients, working closely with them to understand their specific requirements and deliver tailored solutions. Whether it’s a new product development or a redesign of an existing PCB, [Main PCB Assembly Factory] is dedicated to providing cost-effective and reliable services.In addition to its technical capabilities, [Main PCB Assembly Factory] takes pride in its commitment to sustainability and environmental responsibility. The company adheres to strict environmental regulations and strives to minimize its impact on the environment through green manufacturing practices. This includes the use of eco-friendly materials, energy-efficient processes, and waste reduction initiatives.“We are incredibly proud to celebrate 20 years of innovation and excellence in the PCB assembly industry,” said [Spokesperson], CEO of [Main PCB Assembly Factory]. “Since our inception, we have remained committed to delivering high-quality products and exceptional customer service to our clients. This milestone is a testament to the hard work and dedication of our team, as well as the trust and support of our valued customers.”Looking ahead, [Main PCB Assembly Factory] is dedicated to furthering its position as a leader in the electronics manufacturing industry. The company continues to invest in research and development, exploring new technologies and methodologies to enhance its capabilities and offerings. Additionally, [Main PCB Assembly Factory] is focused on expanding its reach and establishing new partnerships to better serve its global customer base.As [Main PCB Assembly Factory] looks to the future, the company remains steadfast in its commitment to excellence, innovation, and customer satisfaction. With a strong foundation built over the past two decades, [Main PCB Assembly Factory] is poised to continue its success and make significant contributions to the electronics manufacturing industry for years to come.For more information about [Main PCB Assembly Factory] and its comprehensive PCB assembly solutions, please visit [website] or contact [contact information].[Contact Information]

Leading Manufacturer of High-Quality PCBA Circuit Boards for Various Industries

Title: Leading PCBA Circuit Board Factory Revolutionizes Electronics ManufacturingIntroduction:(Date, Place) - As the demand for advanced electronic devices continues to soar, the technology industry relies heavily on the production of high-quality printed circuit board assemblies (PCBAs) to enable the seamless functioning of these devices. Breaking new ground in the field, the renowned PCBA Circuit Board Factory leverages state-of-the-art technology and a commitment to innovation to deliver unparalleled PCBAs. Operating under the guidance of their visionary CEO (), this factory guarantees optimal performance, reliability, and affordability in every product they manufacture.Paragraph 1:Founded on the principle of innovation, the PCBA Circuit Board Factory has quickly emerged as a leading player in the electronics manufacturing market. Their cutting-edge facilities, located in (), boast an exceptional combination of advanced machinery, extensive research and development labs, and a highly skilled workforce. These resources, combined with stringent quality control measures, enable the company to consistently deliver top-of-the-line PCBAs that meet the ever-evolving needs of the industry.Paragraph 2:With a commitment to technological advancement, the factory employs an eco-friendly manufacturing process that adheres to international standards for responsible production. The factory's management places great emphasis on sustainability, ensuring that energy consumption is optimized across all stages of production. By minimizing waste and implementing recycling measures, the company maintains its dedication to reducing its ecological footprint.Paragraph 3:In addition to adhering to environmental standards, the PCBA Circuit Board Factory prioritizes its employees' well-being. By offering comprehensive training programs and competitive salaries, the factory attracts and retains a highly skilled workforce. The employees are trained in the latest technologies and industry practices, guaranteeing that each PCBA manufactured is of the highest quality. Furthermore, the factory fosters a dynamic and inclusive work environment that encourages collaboration and innovation.Paragraph 4:The PCBA Circuit Board Factory's dedication to research and development remains one of its key differentiating factors. Investing heavily in R&D, the factory constantly seeks ways to improve its manufacturing processes and enhance product performance. This commitment ensures that the factory stays at the forefront of technological advancements, enabling it to meet customer demands for increasingly complex, versatile, and efficient PCBAs.Paragraph 5:The factory's reputation for exceptional quality has resulted in successful partnerships with renowned electronic device manufacturers across the globe. By consistently delivering reliable and high-performing PCBAs, the factory has built a solid client base that spans industries such as telecommunications, automotive, medical devices, and consumer electronics.Paragraph 6:Looking toward the future, the PCBA Circuit Board Factory aims to expand its global reach and further diversify its product portfolio. By exploring emerging technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and 5G connectivity, the factory positions itself as an industry leader capable of meeting tomorrow's demands. Their commitment to R&D ensures that they are prepared to take on the challenges of new technologies and embrace the opportunities they present.Conclusion:With its state-of-the-art facilities, commitment to quality, and a dedication to innovation, the PCBA Circuit Board Factory has revolutionized the electronics manufacturing industry. By consistently delivering high-quality PCBAs while adhering to environmental and ethical standards, the factory has earned a reputation synonymous with excellence. As the demand for advanced electronic devices continues to grow, this factory is well-positioned to meet and exceed the industry's evolving expectations, cementing their status as a global leader in the field.

Top-quality assembly boards for manufacturing in China: A complete guide

China Assembly Boards (CAB), a leading manufacturer of electronic assembly boards, has announced a major expansion of its operations. The company, known for its high-quality and innovative products, is set to significantly increase its production capacity in response to growing demand for electronic components.Established in 2005, CAB has quickly become a key player in the electronic manufacturing industry. The company boasts state-of-the-art facilities and a team of highly skilled engineers and technicians, enabling it to deliver cutting-edge solutions to its customers. With a focus on quality, reliability, and efficiency, CAB has built a strong reputation for excellence in the industry.The expansion of CAB’s operations comes at a time when the global demand for electronic components is on the rise. As the world becomes increasingly reliant on electronic devices and technologies, the need for high-quality assembly boards has never been greater. CAB is well-positioned to meet this demand, and the company’s expansion plans reflect its commitment to maintaining its position as a market leader.The increased production capacity will allow CAB to better serve its existing customers while also pursuing new opportunities in the market. With a diverse range of products and services, including printed circuit boards, flexible circuit boards, and rigid-flex circuit boards, the company is poised to capitalize on the growing demand for electronic components across various industries.In addition to expanding its production capacity, CAB is also investing in research and development to enhance its product offerings further. The company recognizes the importance of innovation in staying ahead of the competition and meeting the evolving needs of its customers. By leveraging the latest technological advancements and industry best practices, CAB aims to continue delivering high-quality, reliable, and cost-effective solutions to its global clientele."We are excited to announce our expansion plans, which mark a significant milestone for our company," said the spokesperson for CAB. "The increased production capacity and investment in R&D will allow us to better serve our customers and drive the next phase of growth for our business. We are committed to maintaining our position as a leading manufacturer of electronic assembly boards and meeting the needs of our customers in the ever-changing electronics industry."The expansion of CAB’s operations is expected to create new job opportunities and support the local economy. As the company ramps up its production, it will need to hire additional staff to support its increased manufacturing activities. This is welcome news for job seekers in the region and underscores CAB’s contribution to the communities in which it operates.Furthermore, the expansion will also have a positive impact on CAB’s supply chain partners and other stakeholders. As the company increases its production, it will require a greater volume of raw materials and components, creating new business opportunities for its suppliers. This ripple effect will extend to other businesses in the industry, contributing to overall economic growth and prosperity.In conclusion, the expansion of China Assembly Boards represents a significant development for the company and the electronic manufacturing industry as a whole. With its focus on quality, innovation, and customer satisfaction, CAB is well-positioned to leverage the growing demand for electronic components and maintain its leadership position in the market. The company’s commitment to expanding its operations, investing in research and development, and contributing to the local economy bodes well for its future success and continued growth.

Complete Guide to Surface Mount PCB Assembly Services

[Company Name] Announces Expansion of Surface Mount PCB Assembly[City, State] – [Date] – [Company Name], a leading provider of electronic manufacturing services, is excited to announce the expansion of its surface mount PCB assembly capabilities. With the investment in state-of-the-art equipment and technology, [Company Name] is poised to meet the growing demand for high-quality, reliable PCB assembly services.[Company Name] has been at the forefront of electronic manufacturing for over [number] years, specializing in offering innovative solutions to meet the evolving needs of its customers. The expansion of its surface mount PCB assembly capabilities is a testament to the company's commitment to staying ahead of the curve and providing its clients with the latest and most advanced manufacturing capabilities.The new equipment and technology introduced by [Company Name] will allow for precision placement of surface mount components on PCBs, resulting in improved accuracy, reliability, and efficiency. This will enable [Company Name] to offer a wider range of PCB assembly services to its customers, catering to a diverse set of needs and requirements."We are thrilled to announce the expansion of our surface mount PCB assembly capabilities," said [Spokesperson] of [Company Name]. "This investment represents our dedication to providing our customers with the highest quality manufacturing services. With the latest equipment and technology at our disposal, we can ensure that our PCB assembly processes are more advanced than ever, resulting in superior products for our clients."The expanded surface mount PCB assembly capabilities at [Company Name] will benefit a wide range of industries, including aerospace, automotive, consumer electronics, medical devices, and more. The company is well-positioned to serve the needs of clients in these sectors, delivering solutions that meet their specific requirements and standards.In addition to the expansion of its surface mount PCB assembly capabilities, [Company Name] continues to emphasize its commitment to quality, reliability, and customer satisfaction. The company adheres to strict quality control measures throughout the manufacturing process, ensuring that every product that leaves its facility meets the highest standards of excellence.Furthermore, [Company Name] takes a customer-centric approach to its services, working closely with clients to understand their unique needs and preferences. This collaborative approach allows [Company Name] to offer tailored solutions that address the specific challenges and goals of each customer, fostering strong and long-lasting partnerships.As [Company Name] continues to expand its surface mount PCB assembly capabilities, the company remains dedicated to staying at the forefront of electronic manufacturing. By investing in the latest technology and equipment, [Company Name] is well-equipped to meet the evolving demands of the industry and provide its customers with the most advanced and reliable solutions available.To learn more about [Company Name] and its electronic manufacturing services, visit [company website] or contact the company directly at [contact information].About [Company Name]:[Company Name] is a leading provider of electronic manufacturing services, specializing in PCB assembly, prototyping, testing, and more. With over [number] years of experience, [Company Name] is committed to delivering innovative and reliable solutions to meet the unique needs of its customers. The company's state-of-the-art facility and dedicated team of professionals ensure the highest levels of quality and customer satisfaction.