High-Quality Circuit Board Factories: What You Need to Know

By:Admin

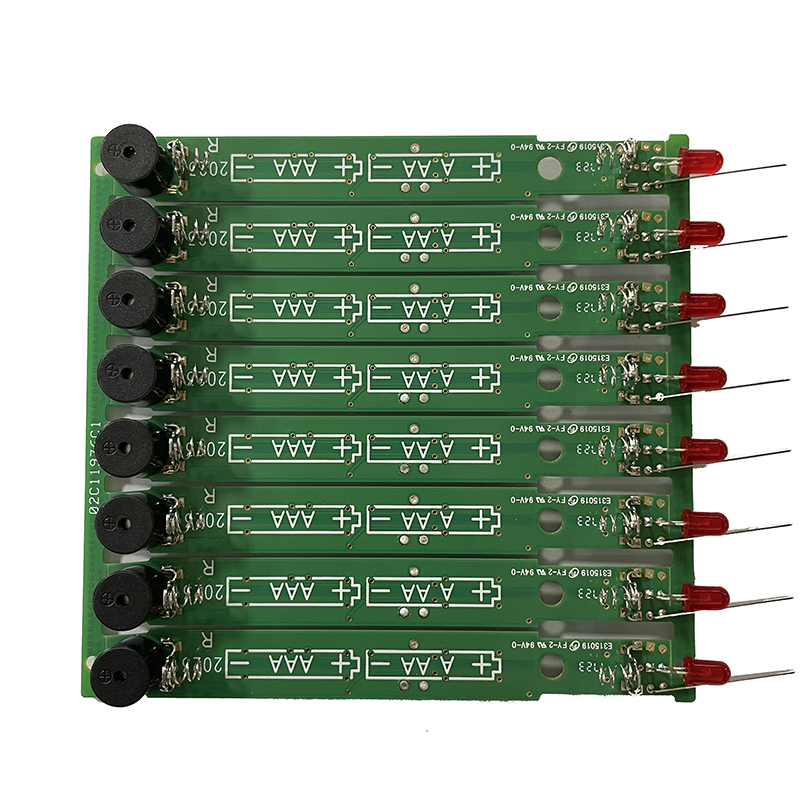

Smt Circuit Board Factories, a leading manufacturer of high-quality circuit boards, has announced plans to expand its operations in response to increasing demand for its products. The company, which has been in business for over 20 years, is known for its cutting-edge technology and commitment to producing reliable and efficient circuit boards for a wide range of industries.

The expansion will involve the construction of a new state-of-the-art manufacturing facility, which will be equipped with the latest in automation and robotics technology to streamline production processes and increase efficiency. The new facility will also allow Smt Circuit Board Factories to significantly increase its production capacity, enabling the company to meet the growing demand for its products both domestically and internationally.

In addition to the new manufacturing facility, Smt Circuit Board Factories also plans to invest in research and development to further enhance its product offerings. The company is committed to staying at the forefront of technological advancements in the industry and is dedicated to continually improving its products to meet the evolving needs of its customers.

Smt Circuit Board Factories has built a strong reputation for providing high-quality products and exceptional customer service. The company's team of experienced engineers and technical staff are dedicated to ensuring that every circuit board that leaves their facility meets the highest standards of quality and reliability. This commitment to excellence has earned Smt Circuit Board Factories the trust and respect of its customers, who rely on the company to deliver products that meet their exact specifications and performance requirements.

The decision to expand operations comes at a time when the demand for high-quality circuit boards is on the rise. As industries such as automotive, aerospace, healthcare, and telecommunications continue to advance technologically, the need for reliable circuit boards to power these innovations has never been greater. Smt Circuit Board Factories is well-positioned to meet this demand and is dedicated to providing the products and services that its customers need to succeed in their respective industries.

The expansion of operations is expected to create new job opportunities in the local community, as Smt Circuit Board Factories plans to hire additional staff to support its growing operations. The company is committed to making a positive impact in the areas where it operates and to contributing to the economic growth and development of the region.

"We are excited to announce our plans to expand our operations to better serve our customers and meet the increasing demand for our products," said the CEO of Smt Circuit Board Factories. "This expansion represents a significant investment in the future of our company and demonstrates our commitment to remaining a leader in the industry. We look forward to the new opportunities this expansion will bring, both for our company and for the community."

The expansion of Smt Circuit Board Factories' operations is a testament to the company's dedication to innovation, quality, and customer satisfaction. With the construction of a new manufacturing facility and investment in research and development, the company is well-positioned to continue meeting the evolving needs of its customers and to drive further growth and success in the years to come.

Company News & Blog

Quality Electrical Components Manufacturing Factory: A Deep Dive into the Industry

Electrical Components Factory Celebrates Fifty Years of Innovation and GrowthFor over fifty years, Electrical Components Factory has been a leading manufacturer and supplier of high-quality electrical components and solutions. Located in the heart of the industrial district, the company has been a driving force in the development of technological advancements and has played a crucial role in shaping the future of the electrical industry.Founded in 1970 by a team of innovative engineers, Electrical Components Factory has grown from a small start-up to a globally recognized brand known for its dedication to quality, reliability, and customer satisfaction. With a strong focus on research and development, the company has continuously introduced groundbreaking products and technologies that have set new industry standards and have contributed to the advancement of the electrical sector.The factory's state-of-the-art facilities house cutting-edge machinery and equipment, enabling the production of a wide range of electrical components including circuit breakers, switches, relays, and connectors. The company's commitment to quality is reflected in its stringent quality control processes and certifications, ensuring that its products meet the highest industry standards and regulations.In addition to its manufacturing capabilities, Electrical Components Factory also boasts a highly skilled team of engineers, designers, and technicians who are dedicated to providing custom solutions and technical support to meet the specific needs of its customers. The company's comprehensive range of services includes product development, prototyping, testing, and customization, making it a trusted partner for businesses across various industries.To celebrate its fifty years of success, Electrical Components Factory announced plans to expand its production capacity and invest in the latest technology to further enhance its manufacturing processes. The company's commitment to innovation and growth is driven by a vision to continue leading the way in the electrical industry and to meet the evolving needs of its customers."We are proud to have reached this significant milestone and are excited about the future of Electrical Components Factory," said the company's CEO. "Our success over the past fifty years is a testament to the hard work and dedication of our team, as well as the trust and support of our customers. We remain committed to delivering excellence in all aspects of our business and look forward to continuing our legacy of innovation and quality for many years to come."As part of its anniversary celebrations, Electrical Components Factory also announced plans to launch a series of new products and initiatives that will further solidify its position as a leading player in the electrical industry. The company aims to continue its tradition of excellence and to build on its legacy to drive future growth and success.With a reputation for reliability, quality, and innovation, Electrical Components Factory has become a trusted partner for businesses seeking cutting-edge electrical solutions. As the company looks towards the future, it remains dedicated to advancing technological boundaries and delivering unmatched value to its customers, cementing its status as a leader in the electrical industry for years to come.

Top Aluminum Wire Bonding Factories: A Complete Guide

Alabama Wire Bonding Factories sees significant growth in demand for its servicesAlabama Wire Bonding Factories, a leading provider of wire bonding solutions, has recently experienced a surge in demand for its services. The company, headquartered in the heart of Alabama, has been serving a wide range of industries with high-quality wire bonding solutions for many years.With a focus on precision and reliability, Alabama Wire Bonding Factories has become a trusted partner for companies in the automotive, aerospace, medical, and electronics industries. The company's state-of-the-art facilities and highly skilled workforce have enabled it to meet the increasing demand for wire bonding services with exceptional quality and efficiency."We are thrilled to see such a strong demand for our wire bonding services," said the CEO of Alabama Wire Bonding Factories. "We have always been committed to delivering the highest standards of quality and precision, and it's rewarding to see that our efforts are being recognized by our customers."The surge in demand for wire bonding services can be attributed to the growing need for advanced electronics in various industries. As technology continues to advance, the demand for smaller, more complex electronic components has increased significantly, driving the need for reliable wire bonding solutions.Alabama Wire Bonding Factories is well-positioned to meet this demand, with its extensive experience in providing wire bonding services for a wide range of applications. From small-scale projects to large-scale productions, the company is equipped to handle the most complex wire bonding requirements with precision and expertise.In addition to its cutting-edge facilities, Alabama Wire Bonding Factories takes pride in its highly skilled and experienced workforce. The company's team of engineers and technicians are dedicated to ensuring that every project meets the highest standards of quality and reliability."We have built a team that is truly passionate about what they do," said the CEO. "Their expertise and dedication are the driving force behind our ability to deliver exceptional wire bonding solutions to our customers."Alabama Wire Bonding Factories is also committed to staying at the forefront of technological advancements in the wire bonding industry. The company continuously invests in research and development to adopt the latest innovations and techniques, ensuring that it can provide its customers with the most advanced wire bonding solutions available."We understand the importance of staying ahead of the curve in this rapidly evolving industry," the CEO stated. "By investing in the latest technology and continuously improving our processes, we are able to offer our customers the most cutting-edge wire bonding solutions."As the demand for wire bonding services continues to grow, Alabama Wire Bonding Factories is poised to expand its operations to accommodate the increasing workload. The company is currently exploring opportunities to further enhance its capacity and capabilities, ensuring that it can continue to meet the evolving needs of its customers."We are excited about the future of our company and the opportunities that lie ahead," the CEO added. "We are fully committed to meeting the growing demand for wire bonding services, and we are confident that our continued investment in technology and talent will enable us to do so successfully."Alabama Wire Bonding Factories' dedication to quality, precision, and innovation has solidified its position as a leading provider of wire bonding solutions. With a strong focus on customer satisfaction and a relentless pursuit of excellence, the company is well-equipped to meet the increasing demand for its services and continue to thrive in the wire bonding industry.

Understanding the SMT Assembly Process in Factories

Smt Assembly Process Factories, a leading global electronics manufacturing company with a focus on high-quality, precision electronic components and assemblies, has continued to expand its operations and capabilities in response to the increasing demand for advanced electronics across various industries.The company has been at the forefront of providing innovative solutions for the assembly and manufacturing of surface mount technology (SMT) products. SMT is a key process in electronics manufacturing, as it allows for the creation of smaller, lighter, and more efficient electronic devices. With the increasing focus on miniaturization and the integration of advanced functionalities into electronic products, the demand for SMT assembly services has been on the rise.Smt Assembly Process Factories has established itself as a reliable and trusted partner for companies in need of high-quality SMT assembly services. The company offers a wide range of capabilities, including SMT assembly, through-hole assembly, box build assembly, and testing services. This comprehensive range of services has enabled Smt Assembly Process Factories to cater to the diverse needs of its customers, from small startups to large corporations.In addition to its advanced assembly capabilities, Smt Assembly Process Factories has also invested in state-of-the-art equipment and manufacturing facilities to ensure the highest level of precision and quality control. The company's commitment to quality is evident in its adherence to strict manufacturing standards and its implementation of industry-leading quality management systems.One of the key strengths of Smt Assembly Process Factories is its focus on innovation and continuous improvement. The company's dedicated team of engineers and technical experts are constantly exploring new technologies and processes to enhance the efficiency and capabilities of its assembly operations. This commitment to innovation has allowed Smt Assembly Process Factories to stay ahead of the competition and provide its customers with cutting-edge solutions.As part of its expansion efforts, Smt Assembly Process Factories has recently announced the opening of a new manufacturing facility in a strategic location to better serve its global customer base. This new facility is equipped with the latest SMT assembly equipment and is designed to meet the growing demand for high-volume production of electronic components and assemblies.Furthermore, Smt Assembly Process Factories has also expanded its workforce to include a team of highly skilled and experienced professionals who are dedicated to delivering exceptional service and support to customers. The company's workforce consists of individuals with diverse backgrounds and expertise, including engineers, technicians, quality control specialists, and customer service personnel.With its strong focus on quality, innovation, and customer satisfaction, Smt Assembly Process Factories is well-positioned to address the evolving needs of the electronics manufacturing industry. The company's commitment to delivering high-quality products and services has earned it a reputation as a preferred partner for businesses seeking reliable and cost-effective SMT assembly solutions.As the demand for advanced electronics continues to grow, Smt Assembly Process Factories remains committed to staying at the forefront of technological advancements and delivering value-added solutions to its customers. The company's dedication to excellence and its ability to adapt to the changing industry landscape make it a key player in the global electronics manufacturing sector.

Assembly Factory for Box Builds: Everything You Need to Know

The Box Build Assembly Factory From Company XYZCompany XYZ is proud to announce the opening of a new state-of-the-art Box Build Assembly Factory. The factory is located in the heart of the industrial district, equipped with cutting-edge technology and staffed by a team of highly skilled professionals.The factory is dedicated to providing customized solutions for the assembly and production of various electronic and electrical products. This includes the manufacturing of printed circuit board assemblies (PCBAs), plastic and metal enclosures, cable assemblies, and complete box build assemblies.From concept to production, Company XYZ's Box Build Assembly Factory offers a comprehensive range of services to meet the unique needs and specifications of their clients. The factory's capabilities include design and engineering support, prototyping, manufacturing, testing, and fulfillment."We are excited to introduce our new Box Build Assembly Factory to the market," says John Smith, CEO of Company XYZ. "This facility represents our commitment to excellence and innovation in the manufacturing industry. With the latest equipment and a team of highly skilled professionals, we are well-positioned to meet the diverse and evolving needs of our customers."The factory is designed to streamline the production process and optimize efficiency, using advanced technologies and processes to ensure high-quality, cost-effective solutions. This includes automated assembly lines, precision testing equipment, and rigorous quality control measures to maintain the highest standards of reliability and performance.In addition to cutting-edge technology, the factory also places a strong emphasis on sustainability and environmental responsibility. The facility is designed to minimize waste and energy consumption, with a focus on recycling and eco-friendly practices throughout the production process.Company XYZ's Box Build Assembly Factory is poised to serve a wide range of industries, including telecommunications, medical devices, industrial automation, consumer electronics, and more. The factory's flexible and scalable production capabilities make it an ideal partner for both small-scale startups and large-scale enterprises."We understand that each project is unique, and we are dedicated to providing tailored solutions to meet the specific requirements of our clients," says Jane Doe, Operations Manager at Company XYZ. "Our team of engineers and technicians work closely with clients to ensure that their products are manufactured to the highest standards of quality and performance."The opening of the Box Build Assembly Factory represents a significant milestone for Company XYZ, strengthening its position as a leading provider of electronic manufacturing services. With a focus on innovation, quality, and customer satisfaction, the factory is poised to drive continued growth and success for the company in the years to come."We are confident that our new Box Build Assembly Factory will be a game-changer for both Company XYZ and our valued customers," adds John Smith. "We look forward to leveraging our advanced capabilities to deliver exceptional products and services, and to further solidify our reputation as a trusted partner in the manufacturing industry."In summary, the Box Build Assembly Factory from Company XYZ represents a new era in electronic manufacturing, offering cutting-edge technology, streamlined production processes, and a strong commitment to sustainability and customer satisfaction. With a focus on innovation and quality, the factory is poised to meet the diverse and evolving needs of clients across a wide range of industries.

High-Quality and Efficient PCB Prototype Factory for Your Manufacturing Needs

Pcb Prototype Factory, a leading manufacturer of printed circuit boards, has recently made significant advancements in the industry with its cutting-edge production technology and dedication to high-quality products.With a state-of-the-art facility and a team of experienced engineers and technicians, Pcb Prototype Factory is committed to providing top-notch PCB prototypes and assembly services to a wide range of industries, including aerospace, telecommunications, automotive, and consumer electronics.The company's unwavering focus on innovation and customer satisfaction has earned them a solid reputation in the market. Pcb Prototype Factory's advanced capabilities allow them to produce complex PCB prototypes with quick turnaround times, enabling their clients to stay ahead of the competition in today's fast-paced business environment.In addition to their advanced production technology, Pcb Prototype Factory also emphasizes the importance of quality control and testing. Each PCB prototype undergoes rigorous inspection and testing processes to ensure its reliability and performance. This dedication to quality has made Pcb Prototype Factory a trusted partner for many businesses looking for reliable PCB solutions.Furthermore, Pcb Prototype Factory takes pride in its commitment to sustainable and environmentally-friendly manufacturing practices. The company has implemented various measures to minimize its environmental impact, such as using eco-friendly materials and optimizing production processes to reduce waste.In a recent statement, the CEO of Pcb Prototype Factory expressed the company's continual dedication to innovation and high standards in the PCB industry. "We are dedicated to providing our clients with superior PCB prototypes that meet their exact specifications and exceed their expectations. Our team is constantly pushing the boundaries of technology to deliver cutting-edge solutions that empower our clients to thrive in their respective industries," said the CEO.As part of their commitment to excellence, Pcb Prototype Factory is also investing in research and development to stay at the forefront of emerging technologies and industry trends. By staying informed of the latest advancements, the company can offer innovative solutions that meet the evolving needs of their clients.Another key aspect of Pcb Prototype Factory's success is their exceptional customer service. The company prides itself on maintaining strong relationships with clients, offering personalized support, and ensuring clear communication throughout the production process. This customer-centric approach has allowed Pcb Prototype Factory to build long-term partnerships with many of its clients, who value the company's reliability, expertise, and dedication to their success.Looking ahead, Pcb Prototype Factory remains committed to driving innovation and setting new industry standards for PCB prototypes and assembly services. With a strong foundation in advanced technology, quality control, sustainability, and customer service, the company is well-positioned to continue its growth and success in the PCB manufacturing industry.In conclusion, Pcb Prototype Factory's commitment to excellence, innovation, and customer satisfaction sets them apart as a leader in the PCB industry. As they continue to invest in cutting-edge technology, quality control, and sustainable practices, Pcb Prototype Factory is poised to remain at the forefront of the industry and meet the evolving needs of their clients for years to come.

The Complete Guide to Smt Pcb Assembly Process

{}The Smt PCB assembly process is a crucial step in the manufacturing of electronic products. Surface Mount Technology (SMT) PCB assembly involves the use of advanced machinery and equipment to place and solder electronic components onto the surface of a printed circuit board (PCB). This process plays a significant role in the production of high-quality electronic devices, ensuring the precise positioning and soldering of components to create reliable and efficient products.One of the leading companies in the Smt PCB assembly process is {}. With years of experience and a strong reputation in the industry, {} has become a trusted partner for numerous electronic manufacturers. The company has established itself as a pioneer in SMT PCB assembly, offering a wide range of services and solutions to meet the diverse needs of its clients.{} employs a team of highly skilled engineers and technicians who are experts in SMT PCB assembly. The company utilizes state-of-the-art machinery and advanced technologies to ensure the accuracy and efficiency of the assembly process. By adhering to strict quality control standards and utilizing the latest industry advancements, {} is able to deliver superior SMT PCB assembly services that meet the highest standards of excellence.The company's SMT PCB assembly process begins with a thorough review of the client's requirements and specifications. {} works closely with its clients to understand their unique needs and design an assembly process that aligns with their goals. Whether it's a small-scale prototype or a large-scale production run, {} has the capabilities to accommodate various project sizes and complexities.In addition, {} offers a comprehensive range of services beyond just SMT PCB assembly. The company provides full turnkey solutions, including PCB design, fabrication, assembly, and testing. {}'s end-to-end capabilities enable clients to streamline their production processes and achieve cost-effective manufacturing solutions.One of the key advantages of partnering with {} for SMT PCB assembly is the company's commitment to quality and reliability. With a focus on continuous improvement and innovation, {} consistently invests in its equipment and processes to enhance the quality of its services. The company also adheres to industry standards and certifications to ensure that its SMT PCB assembly processes meet the strictest requirements.Furthermore, {} places a strong emphasis on customer satisfaction and support. The company's team of dedicated professionals works closely with clients throughout the entire assembly process, providing regular updates and addressing any concerns or questions that may arise. With a focus on transparency and open communication, {} strives to build lasting partnerships based on trust and mutual success.As the demand for high-quality electronic products continues to grow, the importance of reliable SMT PCB assembly processes cannot be overstated. By leveraging the expertise and capabilities of a reputable partner like {}, electronic manufacturers can ensure that their products meet the highest standards of performance and reliability.In conclusion, {} stands as a leading provider of SMT PCB assembly services, offering a comprehensive range of solutions to meet the diverse needs of its clients. With a focus on quality, reliability, and customer support, the company has established itself as a trusted partner for electronic manufacturers seeking superior SMT PCB assembly processes. As the industry continues to evolve, {} remains committed to delivering excellence in every aspect of its services and driving the success of its clients.

Leading Supplier of Flexible PCB Assembly Services for Electronics

Flexible PCB Assembly Supplier, a leading provider of flexible printed circuit board assembly solutions, has recently announced the expansion of their manufacturing capabilities to meet the growing demand for flexible PCBs in various industries.The company, founded in 2005, has quickly made a name for itself in the electronics and PCB assembly industry with their commitment to quality, innovation, and customer satisfaction. With state-of-the-art facilities and a team of highly skilled engineers, Flexible PCB Assembly Supplier has become a trusted partner for businesses looking for high-quality flexible PCB assembly solutions.With the increasing demand for flexible PCBs in industries such as automotive, aerospace, consumer electronics, and medical devices, Flexible PCB Assembly Supplier has recognized the need to expand their manufacturing capabilities to keep up with the demand. The company has invested in new equipment and technology to ensure that they can continue to provide their customers with the highest quality flexible PCB assembly solutions."We are thrilled to announce the expansion of our manufacturing capabilities to meet the growing demand for flexible PCBs," said the CEO of Flexible PCB Assembly Supplier. "With the advancements in technology and the increasing demand for flexible PCBs in various industries, we are committed to staying ahead of the curve and providing our customers with the best possible solutions."Flexible PCB Assembly Supplier offers a wide range of flexible PCB assembly services, including design, prototyping, manufacturing, and testing. The company works closely with their customers to understand their specific requirements and deliver customized solutions that meet their needs.In addition to their manufacturing capabilities, Flexible PCB Assembly Supplier also prides itself on their dedication to quality and customer satisfaction. The company adheres to strict quality control processes to ensure that every product that leaves their facility meets the highest standards."We understand the importance of quality and reliability in the electronics and PCB assembly industry," said the CEO. "That's why we have implemented rigorous quality control processes to ensure that every product we manufacture meets the highest standards. Our customers can have confidence in the quality and reliability of our flexible PCB assembly solutions."With their expanded manufacturing capabilities and commitment to quality, Flexible PCB Assembly Supplier is well-positioned to continue serving the growing demand for flexible PCBs in various industries. The company's dedication to innovation, customer satisfaction, and quality will undoubtedly solidify their position as a leading provider of flexible PCB assembly solutions.As the demand for flexible PCBs continues to grow, Flexible PCB Assembly Supplier is prepared to meet the needs of their customers and provide innovative solutions that drive success in the electronics industry. With their expanded manufacturing capabilities and commitment to quality, the company is well-equipped to continue leading the way in the flexible PCB assembly industry.

DIP: Understanding the Double In-Line Package Component

Double In-Line Package (DIP) is a type of electronic component packaging that is widely used in the electronics industry. It is often referred to as a dual in-line package because it has two rows of pins that are spaced apart at a standard distance. This type of packaging is commonly used for integrated circuits (ICs), such as microprocessors, memory chips, and other complex electronic components.DIP packages are popular due to their versatility and ease of use. They can be easily mounted and removed from circuit boards, making them ideal for prototyping and testing electronic circuits. Additionally, DIP packages are relatively inexpensive to produce, making them a cost-effective choice for many electronic applications.One of the leading manufacturers of DIP packages is {}. This company has been a key player in the electronic components industry for over 30 years and has built a strong reputation for producing high-quality and reliable products. With state-of-the-art manufacturing facilities and a team of experienced engineers, {} is at the forefront of innovation and technology in the electronic components market.The company's DIP packages are known for their durability and performance, making them the preferred choice for many electronics manufacturers around the world. {} offers a wide range of DIP packages to meet the diverse needs of its customers, including standard through-hole DIPs, as well as specialized surface-mount DIPs for compact and space-constrained applications.In addition to its standard DIP packages, {} also provides custom packaging solutions to meet the specific requirements of its customers. With its in-house design and production capabilities, the company can create bespoke DIP packages tailored to the unique needs of individual electronic devices and applications.Furthermore, {} is committed to sustainability and environmental responsibility in its manufacturing processes. The company adheres to strict quality control measures to ensure that its DIP packages meet the highest industry standards for performance, reliability, and safety. By leveraging advanced technologies and materials, {} strives to minimize its environmental impact while delivering superior electronic components to its customers.As the demand for electronic devices continues to grow, so does the need for reliable and efficient DIP packages. With its established track record and dedication to excellence, {} is well-positioned to meet the evolving needs of the electronics industry and continue to be a leading provider of DIP packages globally.In conclusion, Double In-Line Packages (DIPs) are an essential component in the electronics industry, and {} is a trusted manufacturer of high-quality DIP packages. With its commitment to innovation, quality, and sustainability, {} is poised to remain a key player in the electronic components market for years to come. As the industry continues to evolve, {} will continue to offer cutting-edge solutions to meet the growing demand for electronic devices and applications. With its focus on customer satisfaction and technological advancement, {} is set to maintain its leadership in the production of DIP packages and contribute to the advancement of the electronics industry.

High-Quality Electronics Supplier: A Reliable Option for Your Business

Ems Electronics Supplier, a leading provider of electronic manufacturing services, has made a significant impact in the electronics industry with its innovative and high-quality electronic components. With a focus on delivering customized solutions to meet the specific needs of its clients, Ems Electronics Supplier has established itself as a reliable and trusted partner for businesses across various sectors.Established in [year], Ems Electronics Supplier has a proven track record of delivering cutting-edge electronic manufacturing services to its clients. The company specializes in providing a wide range of electronic components, including printed circuit boards, electronic connectors, and integrated circuits, among others. Ems Electronics Supplier is known for its commitment to quality and reliability, ensuring that its clients receive products that meet the highest standards of performance and durability.One of the key factors that set Ems Electronics Supplier apart from its competitors is its dedication to innovation and technological advancement. The company invests heavily in research and development, constantly seeking to improve its products and services to meet the evolving needs of the electronics industry. By staying at the forefront of technological advancements, Ems Electronics Supplier is able to offer its clients the most advanced and efficient electronic components on the market.In addition to its focus on innovation, Ems Electronics Supplier is also committed to sustainability and environmental responsibility. The company adheres to stringent environmental standards in its manufacturing processes, ensuring that its operations have minimal impact on the environment. By integrating sustainable practices into its business model, Ems Electronics Supplier positions itself as a leader in environmental stewardship within the electronics industry.Furthermore, Ems Electronics Supplier places a strong emphasis on customer satisfaction and building long-lasting relationships with its clients. The company works closely with its clients to understand their specific requirements and provide tailored solutions to meet their needs. With a customer-centric approach, Ems Electronics Supplier has earned a reputation for delivering exceptional service and support to its clients, ensuring that they receive the highest level of satisfaction.In recent news, Ems Electronics Supplier has announced the launch of a new line of electronic components that further demonstrates the company's commitment to innovation and quality. The new line includes advanced printed circuit boards with enhanced durability and performance capabilities, as well as electronic connectors with improved efficiency and reliability. These new products are set to revolutionize the electronics industry, offering businesses access to cutting-edge components that will enhance the performance and functionality of their electronic devices."We are thrilled to introduce our new line of electronic components, which represents the next step in our ongoing commitment to providing our clients with the best-in-class solutions," said [spokesperson], [title] at Ems Electronics Supplier. "These new products underscore our dedication to innovation and quality, and we are confident that they will make a significant impact in the electronics industry."In addition to the new product line, Ems Electronics Supplier has also expanded its manufacturing capabilities to meet the growing demand for its electronic components. The company has invested in state-of-the-art equipment and technology to increase its production capacity and efficiency, ensuring that it can continue to meet the needs of its clients on a global scale.As Ems Electronics Supplier continues to make strides in the electronics industry, it remains committed to its core values of innovation, quality, sustainability, and customer satisfaction. With a focus on delivering advanced electronic components and tailored solutions, the company is poised to remain a leader in the electronic manufacturing services sector for years to come.

Exploring the Thriving Electronic Assembly Industry: A Comprehensive Overview

[News Headline]Electronic Assembly Industry Expecting Significant Growth Opportunity in the Coming Years[News Content]The Electronic Assembly industry is set to experience substantial growth in the foreseeable future, driven by advancements in technology, increasing demand for electronic devices, and a growing emphasis on connectivity and automation. With the market projected to expand at a rapid pace, several key players, including {}, are well-positioned to capitalize on this opportunity.The Electronic Assembly industry refers to the process of manufacturing and piecing together electronic components to create functional electronic devices, such as smartphones, laptops, televisions, and more. This sector plays a vital role in the overall electronics industry, providing the necessary expertise and infrastructure for the production of these complex devices.Technological advancements have been a major catalyst for the growth of the Electronic Assembly industry. As consumer preferences shift towards smarter and more sophisticated electronic devices, companies are constantly investing in research and development to stay ahead of the curve. The ongoing development of innovative technologies like 5G, Internet of Things (IoT), artificial intelligence (AI), and virtual reality (VR) has created a huge demand for electronic assemblies that can support these functionalities.Additionally, the global electronics market has witnessed a surge in demand for electronic devices due to increased urbanization, rising disposable incomes, and changing lifestyles. As a result, manufacturers in the Electronic Assembly industry are ramping up production capacities to meet the growing needs of consumers. This has led to a robust market outlook with promising growth potential.One such player in the Electronic Assembly industry is {}, a leading company specializing in electronic assembly services. With extensive experience and a state-of-the-art manufacturing facility, {} is well-equipped to cater to the increasing demands of the market. The company offers a wide range of services, including printed circuit board assembly (PCBA), surface mount technology (SMT), and electronic manufacturing services (EMS), among others.{} has been at the forefront of technological advancements, incorporating cutting-edge equipment and processes into its manufacturing operations. This allows the company to deliver high-quality electronic assemblies that meet the stringent requirements of its clients. By leveraging its expertise and capabilities, {} aims to capture a significant share of the growing Electronic Assembly market.The COVID-19 pandemic has further emphasized the need for reliable and efficient electronic devices. As remote work, online education, and telemedicine become the new norm, electronic assemblies play a crucial role in facilitating these activities. The pandemic has accelerated the adoption of digital solutions and led to an increased demand for electronic devices across various sectors. This scenario, coupled with the anticipated recovery of economies worldwide, presents a golden opportunity for {} and other companies in the Electronic Assembly industry.Looking ahead, the Electronic Assembly industry is expected to witness continued growth, driven by factors such as technological advancements, increasing demand for electronic devices, and the ongoing trend towards connectivity and automation. As the market expands, companies like {} are well-positioned to leverage their expertise and cater to the evolving needs of consumers.In conclusion, the Electronic Assembly industry is poised for significant growth in the coming years. With increasing reliance on electronic devices and technological advancements driving the market, companies like {} have the potential to thrive and deliver innovative electronic assemblies. As the world becomes increasingly connected, the Electronic Assembly industry will play a crucial role in shaping the future of technology and connectivity.