High-Quality PCB Assembly Services for Your Electronics Needs

By:Admin

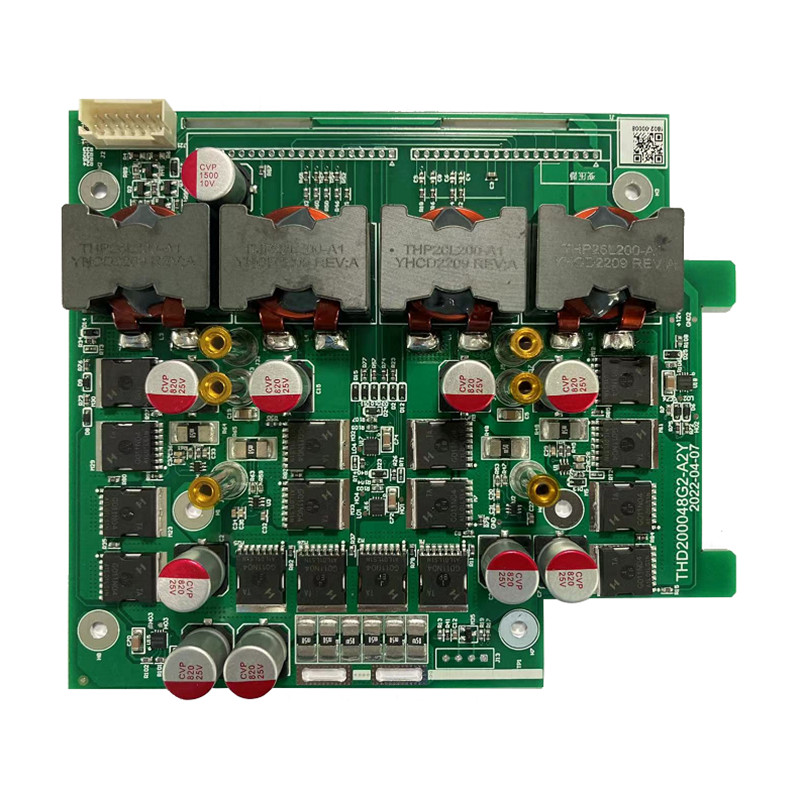

The company specializes in providing comprehensive PCB assembly services, including surface mount technology (SMT) assembly, through-hole assembly, and mixed technology assembly. Equipped with state-of-the-art equipment and a team of experienced technicians, Pcb Assembly House is capable of handling complex PCB assembly projects with utmost precision and attention to detail.

One of the key factors that sets Pcb Assembly House apart from its competitors is its commitment to quality assurance. The company adheres to strict quality control measures at every stage of the assembly process, ensuring that each PCB assembly meets the highest industry standards. From initial design verification to final assembly inspection, Pcb Assembly House leaves no stone unturned in its pursuit of excellence.

In addition to its commitment to quality, Pcb Assembly House also places a strong emphasis on efficiency and cost-effectiveness. By leveraging advanced manufacturing technologies and streamlined processes, the company is able to offer quick turnaround times without compromising on the quality of the end product. This combination of speed and precision gives Pcb Assembly House a competitive edge in the electronic manufacturing industry.

Furthermore, Pcb Assembly House is dedicated to building strong and lasting relationships with its clients. The company takes a collaborative approach to project management, working closely with customers to understand their unique requirements and provide tailored solutions that meet their specific needs. This personalized approach, coupled with the company's unwavering commitment to customer satisfaction, has earned Pcb Assembly House the trust and loyalty of a diverse range of clients across various industries.

In recent news, Pcb Assembly House has announced the expansion of its production capabilities to meet the growing demand for its services. The company has invested in new equipment and technology upgrades, enabling it to take on larger and more complex PCB assembly projects. This expansion is a testament to Pcb Assembly House's continued dedication to staying ahead of industry trends and exceeding customer expectations.

"We are thrilled to announce the expansion of our production capabilities," said [Spokesperson], [Position] at Pcb Assembly House. "This investment allows us to not only increase our capacity but also enhance our ability to deliver high-quality PCB assembly solutions to our clients. We are confident that this expansion will enable us to better serve the evolving needs of the electronic manufacturing industry."

The expansion of Pcb Assembly House's production capabilities comes at a time when the demand for reliable and efficient electronic manufacturing services is on the rise. With an increasing number of businesses turning to outsourcing for their PCB assembly needs, Pcb Assembly House is well-positioned to meet this demand and continue its track record of excellence in the industry.

As Pcb Assembly House looks towards the future, the company remains committed to upholding its core values of quality, efficiency, and customer satisfaction. By staying at the forefront of technological advancements and investing in its capabilities, Pcb Assembly House is poised to remain a leader in the electronic manufacturing sector for years to come.

Company News & Blog

Introducing the Latest Advances in Electronics Manufacturing - Stay Ahead in the Industry!

Title: Leading Electronics Manufacturer Showcases Innovative Solutions for the FutureIntroduction:In a rapidly advancing technological landscape, Ems Electronics has emerged as a frontrunner in providing cutting-edge electronic solutions. With a strong reputation for quality and customer satisfaction, Ems Electronics has become a leading player in the industry. This article will delve into Ems Electronics' exceptional product offerings, recent achievements, and their commitment to shaping the future of electronics.Building a Legacy of Excellence:With a rich history spanning over three decades, Ems Electronics has consistently excelled in manufacturing a wide range of electronic products. Striving for perfection, the company has garnered an impressive list of satisfied clients. Ems Electronics' commitment to innovation, quality, and reliability has catapulted them to the forefront of the industry.Pushing the Boundaries of Technology:Ems Electronics specializes in developing cutting-edge electronic solutions that meet the evolving needs of businesses and consumers alike. The company's portfolio encompasses a comprehensive range of products, including consumer electronics, industrial automation systems, telecommunications equipment, and automotive components. Maintaining a forward-thinking approach, Ems Electronics consistently pushes the boundaries of technology to develop state-of-the-art products.Investing in Research and Development:At Ems Electronics, research and development (R&D) plays a pivotal role in driving success. The company continuously invests in R&D to stay at the forefront of technological advancements. By collaborating with industry-leading experts and leveraging the latest tools and techniques, Ems Electronics ensures that their products remain ahead of the curve. The company's commitment to innovation has allowed it to anticipate future trends and develop products that align with market demands.Strategic Partnerships and Collaborations:Recognizing the importance of collaboration, Ems Electronics actively seeks partnerships with other industry players, research institutions, and startups. By fostering collaborations, the company gains access to a diverse pool of talent and resources. Such partnerships enable Ems Electronics to develop groundbreaking solutions in a more efficient and cost-effective manner. Additionally, these collaborations facilitate knowledge exchange and enhance the company's overall industry presence.Ensuring Product Quality and Compliance:Ems Electronics places the utmost importance on maintaining product quality and meeting stringent regulatory standards. The company follows rigorous quality control measures and adheres to industry-specific certifications. By implementing robust quality assurance protocols, Ems Electronics guarantees that their products are reliable, durable, and safe for use.A Sustainable Future:Ems Electronics recognizes the significance of sustainability in the electronics industry. The company embraces environmentally friendly practices throughout the manufacturing process, focusing on reducing waste, energy consumption, and greenhouse gas emissions. By prioritizing sustainability, Ems Electronics ensures a greener future for generations to come.Empowering Workforce and Local Communities:Ems Electronics prides itself on its dedicated workforce and values its local communities. The company fosters a culture of inclusivity, continuous learning, and personal growth within its team. Furthermore, Ems Electronics actively engages with local communities through various initiatives, supporting education, healthcare, and social welfare programs.Conclusion:Ems Electronics' impressive product portfolio, commitment to innovation, and adherence to quality standards have solidified its position as a leading electronics manufacturer. By investing in research and development, building strategic partnerships, and prioritizing sustainability, the company remains at the forefront of the ever-evolving electronics industry. As Ems Electronics continues to shape the future of electronics, it remains committed to delivering innovative solutions that address the needs of a dynamic world.

Easily Perform PCB Assembly at Home: Step-by-Step Guide and Tips

Title: Pioneering PCB Assembly at Home Solution Revolutionizes Electronics ManufacturingIntroduction:In a groundbreaking move, an innovative electronics manufacturing company has introduced a transformative Printed Circuit Board (PCB) assembly solution that allows users to assemble PCBs from the comfort of their homes. This breakthrough has the potential to revolutionize the electronics industry, providing an accessible and user-friendly solution for electronics enthusiasts, DIYers, and even small-scale manufacturers.Offering a range of impressive features and capabilities, the PCB Assembly at Home solution redefines traditional manufacturing processes and elevates them to a whole new level. The advent of this technology is set to bring about tremendous opportunities for creativity, convenience, and cost-effectiveness.Revolutionizing the Industry:With the introduction of the PCB Assembly at Home solution, the electronics manufacturing industry is on the cusp of a technological revolution. This cutting-edge system enables individuals to assemble PCBs without the need for expensive manufacturing facilities or specialized equipment. The convenience of manufacturing PCBs at home highlights the democratization of electronics production, empowering both professionals and enthusiasts to bring their ideas to life.The Unique Features and Benefits:Powered by state-of-the-art software, the PCB Assembly at Home solution provides a user-friendly interface that guides users through the entire assembly process. The platform seamlessly integrates design, prototyping, and assembly, ensuring a streamlined experience. This breakthrough system eliminates the need for complex manual assembly, reducing the risk of human error and ultimately enhancing the overall quality of the PCBs produced.The versatility of this solution is another aspect that sets it apart. Users can assemble a wide range of PCB types, from simple designs to complex multi-layer boards, catering to diverse needs. The flexibility of this approach fosters innovation, allowing users to experiment with various components, test new designs, and refine their products swiftly.Furthermore, the ability to assemble PCBs at home significantly cuts down on logistics costs and time-consuming processes. Gone are the days of relying on external manufacturers and facing prolonged waiting periods. With this new solution, users save both time and money, giving them the freedom to let their creativity and problem-solving skills flourish.Application in various Industries:The PCB Assembly at Home solution opens up new avenues across multiple sectors, including consumer electronics, IoT devices, robotics, and automotive industries. This innovative approach not only benefits professional electronics manufacturers but also empowers individual entrepreneurs, allowing them to manufacture their own products with ease.Small-scale manufacturers, start-ups, and research laboratories can particularly benefit from this technology. By eliminating the need for outsourcing, they can significantly reduce production costs, accelerate time to market, and gain a competitive edge.Future Implications:The introduction of the PCB Assembly at Home solution brings us one step closer to a future where individuals and small-scale businesses have full control over the entire product development lifecycle. As this technology advances, we can expect further enhancements, such as increased automation, integration with AI algorithms, and connectivity with other manufacturing systems.This revolutionary solution has the potential to spark a wave of innovation, empower individuals, and reshape the current landscape of electronics manufacturing. PCB Assembly at Home ushers in a new era of accessibility, convenience, and cost-effectiveness, cementing its position as a game-changer in the industry.Conclusion:The PCB Assembly at Home solution signifies a monumental shift in the electronics manufacturing industry. With its groundbreaking features, user-friendly interface, and endless possibilities, it holds the promise of democratizing product development, lowering costs, and accelerating innovation. As this technology gains popularity, it is set to transform the way we perceive and drive electronics manufacturing, bringing the future of assembly directly into our homes.

Get High Volume PCB Assembly Services at Competitive Prices

High Volume PCB Assembly: A Milestone for {Company Name}{Company Name} is delighted to announce a major achievement in its pursuit of excellence in electronic manufacturing services. The company has successfully completed a high volume PCB assembly project, marking a significant milestone in its journey to provide top-notch solutions to its clients.{Company Name} is a leading electronic manufacturing services provider, specializing in a wide range of services including PCB assembly, box build assembly, and testing services. With a strong commitment to innovation and quality, the company has been serving clients across various industries including automotive, aerospace, medical, and telecommunications.The recent accomplishment of high volume PCB assembly underscores {Company Name}'s dedication to exceeding customer expectations and delivering superior products. The project involved the assembly of a large number of PCBs with precision and efficiency, showcasing the company's ability to handle complex manufacturing processes at scale.The successful completion of the high volume PCB assembly project was made possible by {Company Name}'s state-of-the-art manufacturing facility, equipped with advanced machinery and cutting-edge technology. The company's highly skilled team of engineers and technicians played a pivotal role in ensuring the seamless execution of the project, adhering to strict quality standards and timelines.{Company Name} takes immense pride in its ability to cater to the dynamic needs of its clients, providing tailored solutions that meet the highest industry standards. The high volume PCB assembly project demonstrates the company's capability to handle large-scale production while upholding the paramount importance of quality and accuracy.The accomplishment also reinforces {Company Name}'s position as a trusted partner for businesses seeking reliable and efficient electronic manufacturing services. The company's track record of delivering exceptional results, coupled with its relentless pursuit of excellence, has positioned it as a preferred choice for clients looking to outsource their manufacturing requirements.With a focus on continuous improvement and technological advancement, {Company Name} remains at the forefront of the electronic manufacturing services industry. The successful completion of the high volume PCB assembly project is a testament to the company's unwavering commitment to staying ahead of the curve and embracing the latest industry trends and best practices.As {Company Name} continues to expand its global presence and forge new partnerships, the recent achievement in high volume PCB assembly serves as a testament to the company's capabilities and reinforces its position as a leader in the electronic manufacturing services space. The company remains dedicated to driving innovation, delivering exceptional value, and exceeding customer expectations.Looking ahead, {Company Name} is poised to further elevate its capabilities and expand its service offerings, solidifying its position as a trusted partner for businesses seeking high-quality electronic manufacturing solutions. With a focus on sustainability, efficiency, and customer satisfaction, the company is well-positioned to meet the evolving needs of the industry and drive positive change through its innovative approach to electronic manufacturing services.In conclusion, the successful completion of the high volume PCB assembly project is a significant achievement for {Company Name} and a reflection of its unwavering commitment to excellence. The company's dedication to delivering superior results and its relentless pursuit of innovation sets it apart as a leading provider of electronic manufacturing services. As {Company Name} continues to thrive and expand, it remains steadfast in its mission to provide exceptional solutions and drive positive impact in the industry.

Complete Guide to Surface Mount PCB Assembly Services

[Company Name] Announces Expansion of Surface Mount PCB Assembly[City, State] – [Date] – [Company Name], a leading provider of electronic manufacturing services, is excited to announce the expansion of its surface mount PCB assembly capabilities. With the investment in state-of-the-art equipment and technology, [Company Name] is poised to meet the growing demand for high-quality, reliable PCB assembly services.[Company Name] has been at the forefront of electronic manufacturing for over [number] years, specializing in offering innovative solutions to meet the evolving needs of its customers. The expansion of its surface mount PCB assembly capabilities is a testament to the company's commitment to staying ahead of the curve and providing its clients with the latest and most advanced manufacturing capabilities.The new equipment and technology introduced by [Company Name] will allow for precision placement of surface mount components on PCBs, resulting in improved accuracy, reliability, and efficiency. This will enable [Company Name] to offer a wider range of PCB assembly services to its customers, catering to a diverse set of needs and requirements."We are thrilled to announce the expansion of our surface mount PCB assembly capabilities," said [Spokesperson] of [Company Name]. "This investment represents our dedication to providing our customers with the highest quality manufacturing services. With the latest equipment and technology at our disposal, we can ensure that our PCB assembly processes are more advanced than ever, resulting in superior products for our clients."The expanded surface mount PCB assembly capabilities at [Company Name] will benefit a wide range of industries, including aerospace, automotive, consumer electronics, medical devices, and more. The company is well-positioned to serve the needs of clients in these sectors, delivering solutions that meet their specific requirements and standards.In addition to the expansion of its surface mount PCB assembly capabilities, [Company Name] continues to emphasize its commitment to quality, reliability, and customer satisfaction. The company adheres to strict quality control measures throughout the manufacturing process, ensuring that every product that leaves its facility meets the highest standards of excellence.Furthermore, [Company Name] takes a customer-centric approach to its services, working closely with clients to understand their unique needs and preferences. This collaborative approach allows [Company Name] to offer tailored solutions that address the specific challenges and goals of each customer, fostering strong and long-lasting partnerships.As [Company Name] continues to expand its surface mount PCB assembly capabilities, the company remains dedicated to staying at the forefront of electronic manufacturing. By investing in the latest technology and equipment, [Company Name] is well-equipped to meet the evolving demands of the industry and provide its customers with the most advanced and reliable solutions available.To learn more about [Company Name] and its electronic manufacturing services, visit [company website] or contact the company directly at [contact information].About [Company Name]:[Company Name] is a leading provider of electronic manufacturing services, specializing in PCB assembly, prototyping, testing, and more. With over [number] years of experience, [Company Name] is committed to delivering innovative and reliable solutions to meet the unique needs of its customers. The company's state-of-the-art facility and dedicated team of professionals ensure the highest levels of quality and customer satisfaction.

Gold Ribbon Bonding Supplier: Meeting Demands for Quality Bonding Services

[Company Introduction][Company Name] is a leading provider of innovative bonding solutions in the electronics industry. With a focus on research and development, our company is committed to supplying high-quality gold ribbon bonding products to manufacturers worldwide. As a trusted partner, we strive to meet the ever-evolving demands of our customers, enabling them to enhance the performance and reliability of their electronic devices.Our state-of-the-art manufacturing facilities, coupled with an experienced team of engineers and technicians, position us at the forefront of the industry. We take pride in our ability to deliver customized solutions tailored to our customers' specific requirements. Whether it is bonding wires for semiconductors, LED packages, or any other electronic component, our gold ribbon bonding products are designed to provide exceptional conductivity and stability, ensuring the longevity of electronic devices in diverse applications.With a strong emphasis on technological innovation, we constantly invest in research and development activities. Our dedicated team of engineers collaborates with industry experts and academic institutions to explore novel bonding techniques and materials. This commitment to innovation drives us to continuously improve our products and offer advanced bonding solutions that empower our customers to excel in a highly competitive market.In addition to our dedication to quality and innovation, we place great importance on sustainability and environmental responsibility. Our manufacturing processes adhere to stringent environmental regulations and best practices, striving to minimize the impact on the planet while maintaining the highest standards of product performance. We are committed to promoting sustainability across the industry and actively seek partnerships with like-minded organizations to drive positive change.[News][Date], [Company Name] announced its latest breakthrough in the field of gold ribbon bonding, revolutionizing the electronics industry with its advanced bonding products and techniques. The company's continued commitment to technological innovation has positioned it as a leading supplier of gold ribbon bonding solutions, catering to the diverse needs of manufacturers worldwide.The new range of gold ribbon bonding products introduced by [Company Name] offers improved conductivity, reliability, and ease of use. With enhanced performance characteristics, manufacturers can now improve the efficiency and functionality of their electronic devices, meeting the ever-increasing demands of consumers in today's digital age.One of the key highlights of the new product line is its compatibility with a wide range of electronic components. Whether it is bonding wires for semiconductors, LED packages, or other critical components, [Company Name]'s gold ribbon bonding products ensure seamless integration, providing manufacturers with a versatile solution suitable for various applications.The advanced bonding techniques developed by [Company Name] have also been met with great enthusiasm within the industry. By leveraging state-of-the-art manufacturing processes and materials, the company has significantly increased the bond strength and durability of its gold ribbon bonding products. This breakthrough not only enhances the lifespan of electronic devices but also improves their resistance to environmental factors such as temperature fluctuations and mechanical stress.Furthermore, [Company Name]'s commitment to sustainability has resulted in the development of eco-friendly gold ribbon bonding solutions. These products adhere to the highest environmental standards, without compromising on performance or reliability. As electronic waste continues to be a growing concern, [Company Name] aims to provide manufacturers with innovative bonding solutions that minimize environmental impact and promote a more sustainable electronics industry.As a leading bonding supplier, [Company Name]'s dedication to customer satisfaction remains unparalleled. The company's global network of experts ensures comprehensive technical support and reliable customer service, aiding manufacturers in every step of their bonding processes. By fostering long-term partnerships with clients, [Company Name] continually adapts its solutions to align with the evolving needs of the electronics industry.With its latest advancements in gold ribbon bonding, [Company Name] sets a new benchmark for excellence in the electronics industry. By combining innovation, sustainability, and customer-centricity, the company reaffirms its position as a trusted partner for manufacturers seeking cutting-edge bonding solutions. As the industry continues to evolve, [Company Name] remains committed to pushing the boundaries of gold ribbon bonding technology, empowering manufacturers to deliver high-performance electronic devices that shape the world we live in.

Benefits of Using High-Quality Gold Wire Bonding for Electronics Applications

High-Quality Gold Wire Bonding Technology Revolutionizes Electronics IndustryGold wire bonding has long been a cornerstone of the electronics industry, providing a reliable and efficient method for connecting semiconductor chips to the packaging substrate. This critical process is essential for the production of a wide range of electronic devices, from smartphones and tablets to automotive electronics and medical devices. However, the demand for higher performance and reliability in electronic devices has driven the need for improvements in gold wire bonding technology. The introduction of high-quality gold wire bonding by {Company Name}, a leading provider of advanced packaging and interconnect solutions, is set to revolutionize the industry and meet these growing demands.{Company Name} has been at the forefront of innovation in the electronics industry for over 30 years, developing cutting-edge solutions to meet the ever-evolving needs of the market. With a strong focus on research and development, the company has continuously invested in advancing its wire bonding technology to deliver high-quality and high-performance solutions to its customers. The new high-quality gold wire bonding technology represents the latest achievement in this ongoing commitment to innovation.The key to {Company Name}'s high-quality gold wire bonding technology lies in its advanced manufacturing processes and materials. The company has developed proprietary techniques for producing ultra-fine gold wires with exceptional purity and consistency. These wires are then bonded to semiconductor chips with unparalleled precision and reliability, ensuring robust connectivity and signal integrity. This level of quality is essential for meeting the rigorous performance and reliability requirements of modern electronic devices.In addition to its superior performance, {Company Name}'s high-quality gold wire bonding technology also offers significant cost advantages. The company's advanced manufacturing processes allow for higher throughput and yield, resulting in lower production costs for its customers. Furthermore, the exceptional reliability of the bonding process minimizes the risk of in-field failures, reducing warranty and support costs for electronic device manufacturers.The impact of {Company Name}'s high-quality gold wire bonding technology is already being felt across the electronics industry. Leading semiconductor manufacturers have embraced this technology to enhance the performance and reliability of their products, giving them a competitive edge in the market. Electronic device manufacturers, in turn, are benefiting from the improved quality and cost-efficiency of their products, driving greater customer satisfaction and loyalty.Beyond its immediate impacts, {Company Name}'s high-quality gold wire bonding technology is also paving the way for the development of next-generation electronic devices. As the demand for smaller, faster, and more reliable electronics continues to grow, the need for advanced interconnect solutions becomes increasingly critical. The exceptional performance and reliability of {Company Name}'s gold wire bonding technology make it well-suited for meeting these future demands, opening up new possibilities for innovation in the electronics industry.Looking ahead, {Company Name} remains dedicated to pushing the boundaries of possibility in the electronics industry. With its high-quality gold wire bonding technology serving as a testament to its commitment to excellence, the company is poised to continue driving innovation and shaping the future of electronic devices. By delivering advanced packaging and interconnect solutions that exceed the expectations of its customers, {Company Name} is cementing its position as a leader in the industry and a driving force for progress.

Leading Manufacturer of High-Quality PCBA Circuit Boards for Various Industries

Title: Leading PCBA Circuit Board Factory Revolutionizes Electronics ManufacturingIntroduction:(Date, Place) - As the demand for advanced electronic devices continues to soar, the technology industry relies heavily on the production of high-quality printed circuit board assemblies (PCBAs) to enable the seamless functioning of these devices. Breaking new ground in the field, the renowned PCBA Circuit Board Factory leverages state-of-the-art technology and a commitment to innovation to deliver unparalleled PCBAs. Operating under the guidance of their visionary CEO (), this factory guarantees optimal performance, reliability, and affordability in every product they manufacture.Paragraph 1:Founded on the principle of innovation, the PCBA Circuit Board Factory has quickly emerged as a leading player in the electronics manufacturing market. Their cutting-edge facilities, located in (), boast an exceptional combination of advanced machinery, extensive research and development labs, and a highly skilled workforce. These resources, combined with stringent quality control measures, enable the company to consistently deliver top-of-the-line PCBAs that meet the ever-evolving needs of the industry.Paragraph 2:With a commitment to technological advancement, the factory employs an eco-friendly manufacturing process that adheres to international standards for responsible production. The factory's management places great emphasis on sustainability, ensuring that energy consumption is optimized across all stages of production. By minimizing waste and implementing recycling measures, the company maintains its dedication to reducing its ecological footprint.Paragraph 3:In addition to adhering to environmental standards, the PCBA Circuit Board Factory prioritizes its employees' well-being. By offering comprehensive training programs and competitive salaries, the factory attracts and retains a highly skilled workforce. The employees are trained in the latest technologies and industry practices, guaranteeing that each PCBA manufactured is of the highest quality. Furthermore, the factory fosters a dynamic and inclusive work environment that encourages collaboration and innovation.Paragraph 4:The PCBA Circuit Board Factory's dedication to research and development remains one of its key differentiating factors. Investing heavily in R&D, the factory constantly seeks ways to improve its manufacturing processes and enhance product performance. This commitment ensures that the factory stays at the forefront of technological advancements, enabling it to meet customer demands for increasingly complex, versatile, and efficient PCBAs.Paragraph 5:The factory's reputation for exceptional quality has resulted in successful partnerships with renowned electronic device manufacturers across the globe. By consistently delivering reliable and high-performing PCBAs, the factory has built a solid client base that spans industries such as telecommunications, automotive, medical devices, and consumer electronics.Paragraph 6:Looking toward the future, the PCBA Circuit Board Factory aims to expand its global reach and further diversify its product portfolio. By exploring emerging technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and 5G connectivity, the factory positions itself as an industry leader capable of meeting tomorrow's demands. Their commitment to R&D ensures that they are prepared to take on the challenges of new technologies and embrace the opportunities they present.Conclusion:With its state-of-the-art facilities, commitment to quality, and a dedication to innovation, the PCBA Circuit Board Factory has revolutionized the electronics manufacturing industry. By consistently delivering high-quality PCBAs while adhering to environmental and ethical standards, the factory has earned a reputation synonymous with excellence. As the demand for advanced electronic devices continues to grow, this factory is well-positioned to meet and exceed the industry's evolving expectations, cementing their status as a global leader in the field.

Pioneering PCB Prototype Factories: A Comprehensive Study Unveils Key Insights

Title: Pioneering PCB Prototype Factories Revolutionize Electronics ManufacturingIntroduction:In today's fast-paced world, the demand for high-quality electronic devices and components is on the rise. To meet this ever-increasing demand, (company name) has emerged as a leader in PCB prototype manufacturing, spearheading a revolutionary change in the electronics manufacturing industry. With state-of-the-art facilities and a commitment to cutting-edge technology, (company name) is setting new standards in PCB production, enhancing efficiency, and delivering top-of-the-line products to consumers worldwide.Section 1: Bridging the Gap between Prototyping and Mass Production (150 words)Traditional PCB manufacturing often faced challenges when transitioning from prototyping to mass production due to compatibility issues and lack of streamlined processes. However, (company name) aims to bridge this gap by offering a seamless transition from prototype to final product. Utilizing advanced technologies, such as automated assembly lines and precision printing, (company name) ensures that the design specifications of the prototype are replicated accurately during mass production. This not only saves time and reduces costs but also minimizes errors and enhances overall production efficiency.Section 2: Cutting-Edge Facilities and Technology (200 words)(Company name)'s success lies in its commitment to maintaining cutting-edge facilities and embracing the latest technological advancements. Its state-of-the-art manufacturing units are equipped with advanced machinery capable of producing high-quality PCB prototypes that meet the most stringent industry standards. The company's research and development team continuously explores innovative techniques to enhance the manufacturing process further.One such breakthrough technology is the use of automated optical inspection (AOI) systems that meticulously examine each PCB prototype for defects, ensuring flawless craftsmanship. Additionally, (company name) employs advanced soldering techniques, such as reflow soldering and surface mount technology, to achieve precision connections and high component density.Section 3: Customization and Flexibility (200 words)Recognizing that each client has unique requirements, (company name) offers unparalleled customization and flexibility in its PCB prototype manufacturing. Whether it's a small-scale project or a large-scale venture, the company can adapt to various specifications and timelines. Through close collaboration with clients, (company name) understands their needs and provides tailored solutions, ensuring complete client satisfaction.Furthermore, (company name)'s prototyping capabilities extend beyond traditional PCB designs. The company specializes in flexible printed circuit boards (FPCBs), rigid-flex PCBs, and multi-layer PCBs. This versatility positions (company name) as a preferred partner for diverse industries, including aerospace, automotive, medical, telecommunications, and consumer electronics.Section 4: Quality Assurance and Certifications (150 words)Maintaining unwavering commitment to quality, (company name) adheres to rigorous quality control processes at every stage. The company has obtained relevant certifications, such as ISO 9001 and UL certification, further reinforcing its dedication to meeting international quality standards. From the sourcing of raw materials to the final inspection, (company name) ensures stringent checks to guarantee reliable, durable, and safe products.Conclusion (100 words)With its cutting-edge facilities, advanced technology, customizability, and unwavering commitment to quality, (company name) is revolutionizing the electronics manufacturing industry. By bridging the gap between prototyping and mass production, the company is empowering businesses to bring their innovative ideas to life swiftly and efficiently. In an era driven by technological advancements, (company name) continues to push the boundaries of what is possible in PCB prototype manufacturing, providing a solid foundation for the development of superior electronic devices that transform the future.

Top Wire Bonding Manufacturer Providing High-Quality Products

Al Wire Bonding Manufacturer, a leading provider of wire bonding solutions, has announced its latest innovation in wire bonding technology. With over 20 years of experience in the industry, Al Wire Bonding Manufacturer has established itself as a reliable and innovative partner for companies in the semiconductor and electronics manufacturing sector.The company specializes in the development and production of wire bonding equipment and materials, offering a comprehensive range of solutions to meet the diverse needs of its customers. From high-speed wire bonders to advanced bonding materials, Al Wire Bonding Manufacturer is dedicated to delivering cutting-edge technology and superior performance to its clients.In line with its commitment to continuous improvement and innovation, Al Wire Bonding Manufacturer has recently introduced a new generation of wire bonding equipment that promises to revolutionize the industry. The latest technology features state-of-the-art automation and precision engineering, allowing for faster production speeds and higher bonding accuracy. This advancement is expected to significantly improve the efficiency and quality of wire bonding processes, ultimately benefiting manufacturers and end-users alike.Moreover, Al Wire Bonding Manufacturer has also expanded its range of bonding materials to include innovative alloys and compositions that offer enhanced conductivity and reliability. These advanced materials are designed to meet the evolving demands of modern electronics, ensuring optimal performance and longevity in various applications.Furthermore, Al Wire Bonding Manufacturer places a strong emphasis on customer satisfaction, providing comprehensive technical support and training programs to assist its clients in maximizing the value of its solutions. The company’s team of experienced engineers and industry experts are dedicated to delivering personalized service and expert guidance to address specific challenges and requirements.With a global presence and a commitment to sustainability, Al Wire Bonding Manufacturer aims to be a trusted partner for companies seeking reliable and high-performance wire bonding solutions. The company’s focus on research and development, as well as its investment in state-of-the-art manufacturing facilities, demonstrates its dedication to delivering exceptional products and services to its customers.In addition to its technological advancements, Al Wire Bonding Manufacturer is also committed to corporate social responsibility, implementing environmentally friendly practices and ethical business standards throughout its operations. The company’s dedication to sustainability and social responsibility is reflected in its commitment to reducing its environmental impact and supporting local communities.As the demand for advanced wire bonding solutions continues to grow in the semiconductor and electronics manufacturing industry, Al Wire Bonding Manufacturer remains at the forefront of innovation and excellence. With its latest technology and comprehensive range of products and services, the company is well-positioned to meet the evolving needs of its customers and contribute to the advancement of the industry.In conclusion, Al Wire Bonding Manufacturer continues to set new standards in the wire bonding industry, leveraging its expertise and dedication to innovation to deliver superior solutions to its customers. With its latest advancements and commitment to customer satisfaction, the company is poised to drive further growth and success in the global market.

High-Quality Chip On Board Factory: A Look into the Cutting-Edge Technology

Chip On Board Factory (COB) has recently announced the opening of its new state-of-the-art facility, marking a significant milestone for the company as it continues to expand its operations and meet the growing demand for advanced semiconductor solutions.The new facility, located in the heart of the technology hub, is equipped with the latest in manufacturing equipment and cutting-edge processes to enable the production of high-performance chips with superior reliability and efficiency. With a focus on the rapidly evolving needs of the industry, COB is committed to delivering innovative solutions that will help drive the next wave of technological advancements across multiple sectors.COB has built a solid reputation for its ability to deliver high-quality chips that are tailored to meet the specific requirements of its customers. By leveraging its extensive R&D capabilities and deep industry expertise, the company has consistently pushed the boundaries of what is possible in semiconductor technology, and the new facility is poised to significantly strengthen its ability to bring game-changing solutions to market."As the demand for advanced chips continues to surge across a wide range of industries, it is essential for us to expand our manufacturing capabilities to keep pace with this rapid growth," said the CEO of COB. "Our new facility represents a significant investment in our future and underscores our unwavering commitment to delivering the highest quality semiconductor solutions to our customers."The new facility is strategically located to take advantage of the robust ecosystem of suppliers, partners, and talent in the area, further enhancing COB's ability to drive innovation and collaboration within the semiconductor industry. By fostering close partnerships with key players in the ecosystem, COB aims to accelerate the development and adoption of cutting-edge technologies that will power the next generation of smart devices, automotive systems, and industrial applications.In addition to serving as a center for high-volume chip manufacturing, the new facility will also house a dedicated research and development lab, where COB's team of engineers and scientists will work on pioneering new semiconductor technologies. This will facilitate rapid prototyping and testing of new chip designs, allowing COB to stay ahead of industry trends and customer demands.The opening of the new facility comes at a time of great momentum for COB, as the company has recently secured several key partnerships and contracts with leading global technology companies. These collaborations will further solidify COB's position as a trusted partner for advanced semiconductor solutions and open up new opportunities for growth in key markets around the world.As COB continues to push the boundaries of what is possible in semiconductor technology, the new facility will play a critical role in enabling the company to scale its operations and meet the increasing demand for high-quality chips. By investing in cutting-edge manufacturing capabilities and fostering a culture of innovation, COB is well-positioned to drive the next wave of technological advancements and deliver value to its customers for years to come.