High-Quality Wire Bonding Manufacturer - A Leader in the Industry

By:Admin

Founded in [year], Au Wire Bonding Manufacturer has quickly established itself as a trusted partner for semiconductor manufacturers around the world. The company's commitment to excellence and its relentless pursuit of innovation have set it apart from its competitors, earning it a reputation as a market leader in wire bonding solutions.

With a state-of-the-art manufacturing facility and a team of dedicated professionals, Au Wire Bonding Manufacturer has the capability to deliver a wide range of products to meet the diverse needs of its customers. From standard wire bonding solutions to customized options, the company has the expertise and resources to provide cutting-edge solutions that are tailored to the specific requirements of each client.

One of the key factors that sets Au Wire Bonding Manufacturer apart from its competitors is its unwavering commitment to quality. The company's rigorous quality control processes and strict adherence to industry standards ensure that every product that leaves its facility is of the highest quality. This dedication to excellence has earned Au Wire Bonding Manufacturer the trust and loyalty of its customers, who rely on the company to deliver reliable, high-performance products time and time again.

In addition to its focus on quality, Au Wire Bonding Manufacturer also prides itself on its customer-centric approach. The company works closely with its customers to understand their specific needs and challenges, and then leverages its expertise to develop tailored solutions that exceed their expectations. Whether it's providing technical support, offering custom solutions, or delivering products on time and on budget, Au Wire Bonding Manufacturer goes above and beyond to ensure its customers' success.

Another key strength of Au Wire Bonding Manufacturer is its investment in research and development. The company recognizes that continuous innovation is essential to staying ahead in the fast-paced semiconductor industry, and as such, it allocates significant resources to R&D. This investment has enabled the company to develop groundbreaking technologies and pioneering solutions that have redefined the wire bonding landscape.

Looking ahead, Au Wire Bonding Manufacturer is poised to continue its upward trajectory, as it remains committed to pushing the boundaries of what is possible in wire bonding technology. With a strong focus on innovation, quality, and customer satisfaction, the company is well-positioned to maintain its leadership in the semiconductor industry and to meet the evolving needs of its global customer base.

In conclusion, Au Wire Bonding Manufacturer has firmly established itself as a market leader in the semiconductor industry, thanks to its unwavering commitment to quality, customer-centric approach, and relentless pursuit of innovation. As the company continues to grow and evolve, it is poised to redefine the wire bonding landscape and set new standards for excellence in the industry.

Company News & Blog

Medical PCB Assembly Services in China

China Medical PCB Assembly Company Leads the Way in Advanced Medical TechnologyAs the medical field continues to advance at a rapid pace, the demand for high-quality medical PCB (Printed Circuit Board) assembly has never been higher. One company that is leading the way in this critical industry is [company name], a renowned manufacturer of advanced medical PCB assemblies in China. With their cutting-edge technology and unwavering commitment to quality, they are playing a crucial role in the development of innovative medical devices that are saving lives and improving patient care around the world.Founded in [year], [company name] has quickly established itself as a trusted partner for medical device manufacturers, thanks to their exceptional quality, unparalleled expertise, and dedication to customer satisfaction. The company specializes in the assembly of PCBs for a wide range of medical applications, including diagnostic equipment, patient monitors, imaging devices, and much more. Their state-of-the-art manufacturing facility is equipped with the latest technology and staffed by a team of highly skilled professionals, ensuring that each PCB assembly meets the strictest standards for reliability, performance, and safety.One of the key strengths of [company name] is their ability to provide customized solutions to meet the unique needs of their clients. With a focus on innovation and continuous improvement, they work closely with medical device manufacturers to develop PCB assemblies that are tailor-made for specific applications. Whether it is a complex multi-layer board or a high-density interconnect PCB, the company has the expertise and capabilities to deliver reliable and cost-effective solutions that meet the highest industry standards.In addition to their technical expertise, [company name] is also committed to upholding the highest standards of quality and compliance. The company is ISO [xx], [xx], and [xx] certified, and their manufacturing processes adhere to the strict regulations set forth by the FDA and other regulatory bodies. This commitment to quality and regulatory compliance ensures that the PCB assemblies produced by [company name] are not only reliable and high-performing but also safe for use in critical medical applications.Furthermore, [company name] takes pride in its ability to provide fast turnaround times and flexible manufacturing solutions to meet the dynamic needs of the medical industry. With a focus on lean manufacturing and continuous process improvement, they are able to streamline production processes and minimize lead times without compromising on quality. This agility and responsiveness have made [company name] a preferred partner for medical device manufacturers who are operating in a fast-paced and competitive market.Looking to the future, [company name] is poised to continue its leadership in the medical PCB assembly industry by staying at the forefront of technological advancements and industry trends. By investing in research and development, fostering strategic partnerships, and expanding their capabilities, the company is well-positioned to meet the evolving demands of the medical device market and contribute to the development of groundbreaking medical technologies.In conclusion, [company name] stands as a shining example of excellence in the field of medical PCB assembly. With their unwavering commitment to quality, technical expertise, and customer-focused approach, they are playing a vital role in advancing medical technology and improving patient care. As the medical industry continues to evolve, [company name] is well-equipped to meet the challenges and opportunities that lie ahead, and their innovative PCB assemblies will undoubtedly continue to shape the future of healthcare worldwide.

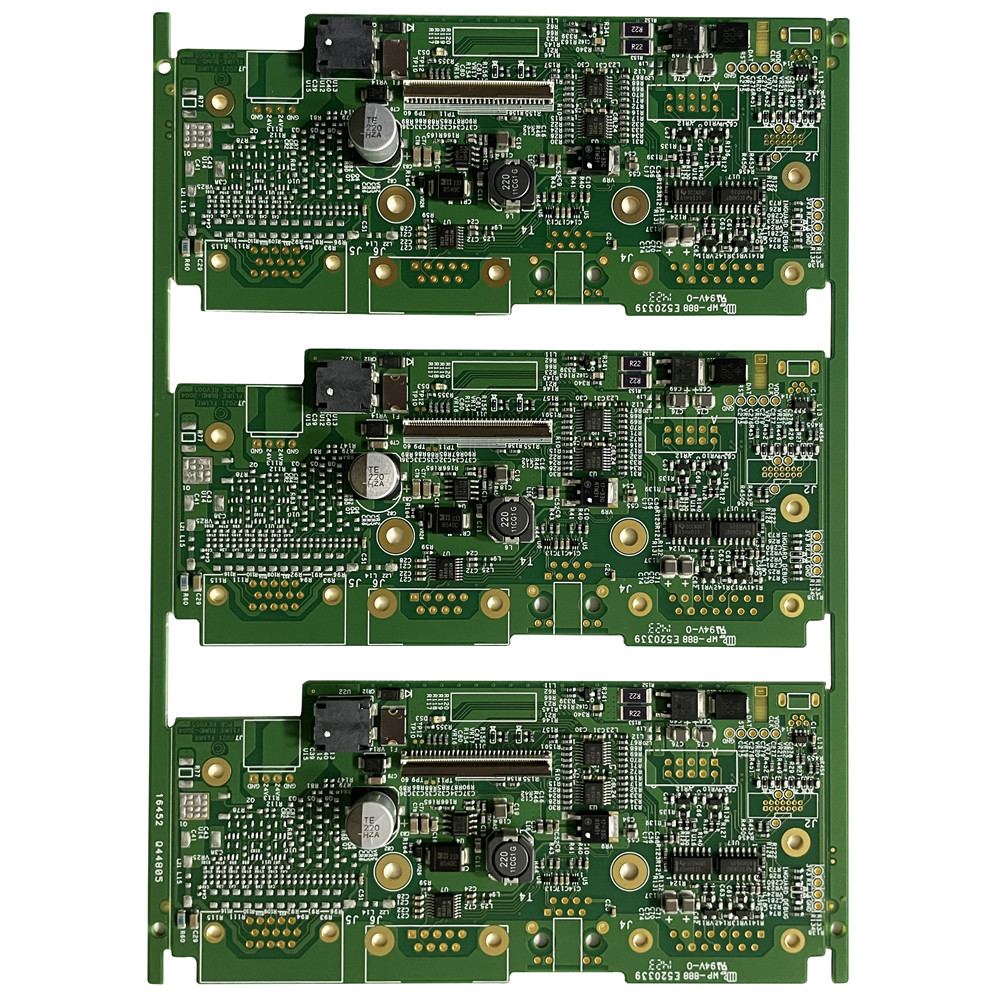

High-quality PCB assembly services for electronic products

Pcb Assembly Company, a leading provider of high-quality printed circuit board assemblies, has announced the expansion of its operations to meet the growing demands of the electronics industry. With state-of-the-art facilities and a team of experienced professionals, the company is well-positioned to provide top-notch PCB assembly services to its clients.With a strong focus on quality and customer satisfaction, Pcb Assembly Company has established itself as a trusted partner for a wide range of industries, including telecommunications, automotive, aerospace, and consumer electronics. The company's commitment to excellence is reflected in its ISO 9001 certification and adherence to strict quality control measures.In addition to its high-quality products, Pcb Assembly Company takes pride in its quick turnaround times and competitive pricing. By leveraging advanced manufacturing technologies and efficient processes, the company is able to deliver superior PCB assemblies while meeting tight deadlines and staying within budget constraints.Moreover, Pcb Assembly Company places a significant emphasis on innovation and continuous improvement. The company invests in ongoing research and development efforts to stay ahead of industry trends and technological advancements, ensuring that its clients have access to the latest and most advanced PCB assembly solutions.Furthermore, Pcb Assembly Company is dedicated to environmental sustainability and responsible manufacturing practices. The company complies with all applicable regulations and standards, and it actively seeks ways to minimize its environmental impact through efficient energy usage and waste reduction initiatives.With its expansion, Pcb Assembly Company is poised to further elevate its position in the PCB assembly industry and cater to the evolving needs of its clients. The company's continued investment in state-of-the-art equipment and training for its workforce ensures that it remains at the forefront of technological innovation and service excellence.In conclusion, Pcb Assembly Company's expansion is a testament to its unwavering commitment to delivering exceptional PCB assembly services to its clients. With a focus on quality, innovation, and customer satisfaction, the company is well-prepared to meet the demands of the electronics industry while upholding its reputation as a reliable and trusted partner.

Quality Electrical Components Manufacturing Factory: A Deep Dive into the Industry

Electrical Components Factory Celebrates Fifty Years of Innovation and GrowthFor over fifty years, Electrical Components Factory has been a leading manufacturer and supplier of high-quality electrical components and solutions. Located in the heart of the industrial district, the company has been a driving force in the development of technological advancements and has played a crucial role in shaping the future of the electrical industry.Founded in 1970 by a team of innovative engineers, Electrical Components Factory has grown from a small start-up to a globally recognized brand known for its dedication to quality, reliability, and customer satisfaction. With a strong focus on research and development, the company has continuously introduced groundbreaking products and technologies that have set new industry standards and have contributed to the advancement of the electrical sector.The factory's state-of-the-art facilities house cutting-edge machinery and equipment, enabling the production of a wide range of electrical components including circuit breakers, switches, relays, and connectors. The company's commitment to quality is reflected in its stringent quality control processes and certifications, ensuring that its products meet the highest industry standards and regulations.In addition to its manufacturing capabilities, Electrical Components Factory also boasts a highly skilled team of engineers, designers, and technicians who are dedicated to providing custom solutions and technical support to meet the specific needs of its customers. The company's comprehensive range of services includes product development, prototyping, testing, and customization, making it a trusted partner for businesses across various industries.To celebrate its fifty years of success, Electrical Components Factory announced plans to expand its production capacity and invest in the latest technology to further enhance its manufacturing processes. The company's commitment to innovation and growth is driven by a vision to continue leading the way in the electrical industry and to meet the evolving needs of its customers."We are proud to have reached this significant milestone and are excited about the future of Electrical Components Factory," said the company's CEO. "Our success over the past fifty years is a testament to the hard work and dedication of our team, as well as the trust and support of our customers. We remain committed to delivering excellence in all aspects of our business and look forward to continuing our legacy of innovation and quality for many years to come."As part of its anniversary celebrations, Electrical Components Factory also announced plans to launch a series of new products and initiatives that will further solidify its position as a leading player in the electrical industry. The company aims to continue its tradition of excellence and to build on its legacy to drive future growth and success.With a reputation for reliability, quality, and innovation, Electrical Components Factory has become a trusted partner for businesses seeking cutting-edge electrical solutions. As the company looks towards the future, it remains dedicated to advancing technological boundaries and delivering unmatched value to its customers, cementing its status as a leader in the electrical industry for years to come.

Discover the Latest Updates on PCB Assembly Factories for Flexible Electronics

Flex PCB Assembly Factory: A Leader in Cutting-Edge Electronics ManufacturingIn an era where technology advancements are taking place at an unprecedented pace, the demand for flexible printed circuit boards (PCBs) has skyrocketed. These PCBs are revolutionizing the electronics industry due to their ability to bend, twist, and conform to various shapes, providing unparalleled design freedom and space optimization. With the growing market, it is imperative to have a reliable and efficient Flex PCB Assembly Factory that can meet the demands of this evolving industry.Introducing {}, a trailblazer in the field of Flex PCB manufacturing and assembly. With their state-of-the-art facilities and expertise, they have cemented their position as a leader in the industry. Their commitment to high-quality products and superior customer service has made them the go-to choice for many renowned electronics brands.{}'s factory is equipped with cutting-edge machinery and automated assembly lines, ensuring precision and efficiency in every product. Their team of highly skilled engineers and technicians has an in-depth understanding of the nuances of Flex PCBs, enabling them to provide customized solutions tailored to meet the unique requirements of each client.The company's customer-centric approach is evident in their focus on building long-lasting relationships with their clients. They not only provide exemplary manufacturing services but also offer comprehensive support throughout the entire product development cycle. From prototyping to volume production, {}, assists their clients at every stage, ensuring a smooth and hassle-free experience.One of the key differentiators that sets {} apart from the competition is their commitment to innovation. They continually invest in research and development to stay at the forefront of technological advancements. Their team of experts actively collaborates with clients, providing valuable insights and suggestions to optimize their PCB designs. This synergy between {} and their clients ensures that the final products boast superior quality and functionality.{} takes quality control seriously, employing stringent testing procedures at every stage of the manufacturing process. They adhere to international standards and certifications to guarantee that every product leaving their factory meets the highest industry standards. This unwavering commitment to quality has earned them a reputation for providing reliable and durable Flex PCBs.Environmental sustainability is another essential aspect of {}'s operations. They prioritize eco-friendly practices and have implemented measures to minimize their carbon footprint. From reducing energy consumption to adopting recyclable materials, {} plays its part in protecting our planet.With a global clientele spanning various industries, {} has established itself as a trusted partner in flex PCB assembly. They cater to diverse sectors such as consumer electronics, automotive, medical, telecommunications, and more. Their ability to cater to a wide range of applications showcases their adaptability and expertise in this dynamic industry.In conclusion, {}'s Flex PCB Assembly Factory is a force to be reckoned with in the electronics manufacturing world. From their cutting-edge facilities to their commitment to innovation, quality control, and sustainability, they have become the go-to choice for companies seeking top-notch flex PCB assembly. With {} as their partner, businesses can bring their visionary electronic designs to life, confident in the product's durability, reliability, and superior performance.

Industry Booms as Mass Production Takes Center Stage

[News Title][Company Name] Embarks on Mass Production to Meet Growing Demands[City, Date] - [Company Name], a leading global manufacturer in [industry], has recently announced its expansion plans for mass production, aimed towards meeting the increasing demands of customers worldwide. This strategic move comes in response to the thriving market and the need to streamline operations and optimize production capabilities.With its inception in [year], [Company Name] has steadily established itself as a pioneer in the [industry] sector. The company's commitment to quality, innovation, and customer satisfaction has earned it a reputable position in the market. Through continuous investment in research and development, [Company Name] has achieved remarkable breakthroughs, allowing it to introduce cutting-edge technology, products, and solutions.Acknowledging the need to keep up with the ever-evolving demands of industries such as [industry] and cater to the global markets, [Company Name] has decided to ramp up its mass production capabilities. The expansion plans involve strategic partnerships, investments in advanced machinery and technology, and the establishment of additional production facilities in key locations.Speaking with optimism about this expansion, [Company Name]'s CEO, [CEO's Name], mentioned, "We are thrilled to announce our ambitious mass production plans. As one of the market leaders in [industry], it is our responsibility to meet the increasing demands of our customers while maintaining the highest standards of quality and efficiency. This strategic move will enable us to stay competitive, satisfy market needs, and strengthen our global presence."The decision to embark on mass production is backed by extensive market research and detailed analysis of industry trends. With numerous successful pilot projects and early adopter programs, [Company Name] has received positive response and reassurance from key customers and stakeholders. The company's commitment to environmental sustainability is also reflected in the implementation of energy-efficient processes and the usage of eco-friendly materials throughout the production cycle.[Company Name]'s mass production plans are set to bring numerous benefits to both the company and its customers. The increased production capacity will lead to shorter lead times and faster delivery of products. Moreover, it will allow for better cost management and improved economies of scale, thereby offering customers competitive pricing options.In addition to meeting the growing demands of existing markets, the expansion will also enable [Company Name] to explore new business opportunities. With enhanced production capabilities, the company aims to expand its reach into untapped markets and cater to emerging customer needs. The increased output will create new employment opportunities, providing a boost to local economies and fostering economic growth.Looking towards the future, [Company Name]'s mass production strategy lays a solid foundation for sustained growth and continued success. The company is committed to maintaining its reputation as a reliable and innovative industry leader by staying at the forefront of technological advancements and constantly improving its manufacturing processes.About [Company Name]:[Company Name] is a global leader in the [industry] sector, specializing in the manufacturing of [products]. With a rich history dating back to [year], the company has continuously strived for excellence through innovation and quality. [Company Name] holds a strong commitment to its customers, sustainability, and social responsibility, making it a preferred choice for businesses worldwide. For more information, please visit [Company Website].Press Contact:[Media Relations Contact Name][Title][Email][Phone Number]

Pcb Assembly Services for Surface Mount Technology

The demand for electronic devices continues to grow, with consumers seeking smaller, more powerful, and more efficient products. To meet this demand, {} has announced the launch of their new surface mount PCB assembly, providing customers with advanced technology and high-quality assembly services.{} is a leading provider of electronic manufacturing services, offering a wide range of solutions for businesses in various industries. With a focus on innovation and customer satisfaction, {} has established itself as a trusted partner for companies seeking reliable and cost-effective electronic manufacturing solutions.The new surface mount PCB assembly is designed to meet the growing demand for compact and high-performance electronic devices. By utilizing state-of-the-art technology and advanced assembly techniques, {} is able to deliver PCBs that are smaller, lighter, and more efficient than traditional through-hole assembly methods.One of the key advantages of surface mount PCB assembly is its ability to accommodate increasingly complex designs. With the growing trend towards miniaturization, electronic devices are becoming smaller and more compact. Surface mount technology allows for the placement of components directly onto the surface of the PCB, making it possible to create smaller and more densely populated circuit boards without sacrificing performance.In addition to its size advantages, surface mount PCB assembly also offers improved performance and reliability. By eliminating the need for drilled holes and the use of leads, surface mount technology reduces the risk of mechanical failures and improves the overall electrical performance of the PCB. This makes it an ideal choice for applications that require high-speed and high-frequency operation.Furthermore, {}'s surface mount PCB assembly process is highly automated, allowing for increased efficiency and cost savings. By utilizing advanced pick-and-place machines and reflow soldering techniques, {} is able to achieve higher levels of precision and consistency in the assembly process. This results in higher-quality PCBs with fewer defects, ultimately saving time and money for their customers.With the launch of their new surface mount PCB assembly, {} is well-positioned to meet the evolving needs of the electronic manufacturing industry. By leveraging their expertise and state-of-the-art facilities, {} is able to provide customers with cutting-edge assembly solutions that are tailored to their specific requirements.As a leading provider of electronic manufacturing services, {} is committed to delivering exceptional value to their customers. Whether it's through their advanced assembly capabilities, innovative solutions, or dedicated customer support, {} strives to exceed expectations and establish long-lasting partnerships with their clients.In conclusion, the launch of {}'s new surface mount PCB assembly represents a significant milestone in the company's commitment to innovation and excellence. By offering advanced technology, high-quality assembly services, and exceptional value, {} is poised to continue serving as a trusted partner for businesses in need of reliable electronic manufacturing solutions.

China PCB Assembly Steps: A Comprehensive Guide to PCB Assembly in China

Title: China PCB Assembly Steps: A Guide to Efficient and Reliable Electronic Manufacturing ProcessesIntroduction:With the rapid advancements in technology, the demand for high-quality and reliable electronic devices has witnessed a significant surge. Chinese companies have emerged as global leaders in the field of PCB (Printed Circuit Board) assembly, offering efficient and cost-effective solutions for the manufacturing of electronic products. In this article, we will delve into the step-by-step process of PCB assembly in China, highlighting the key aspects and advantages that make it a preferred choice among manufacturers worldwide.Section 1: Introduction to PCB Assembly in ChinaChina has become known for its exceptional capabilities in PCB assembly, thanks to its vast industrial infrastructure, skilled labor force, and state-of-the-art equipment. Moreover, the competitive production costs and flexible manufacturing capabilities have made PCB assembly services in China highly sought-after by various industries, including telecommunications, consumer electronics, automotive, aerospace, and medical devices.Section 2: PCB Assembly Steps - Efficiency and Precision2.1 Design and Prototyping:The first step in the PCB assembly process involves design and prototyping. Skilled engineers and designers collaborate with clients to develop a comprehensive layout, ensuring all specifications and requirements are met. With the aid of advanced software tools, the design is then translated into a physical prototype.2.2 Component Sourcing:China's vast network of component suppliers enables efficient sourcing of high-quality electronic components required for PCB assembly. This step involves meticulous verification and selection of components based on their quality, compatibility, and reliability.2.3 PCB Manufacturing:Once the design and components are finalized, PCB manufacturing commences. Specialized equipment ensures the precise etching and fabrication of the PCB, adhering to high-quality standards specified by international regulations.2.4 SMT Assembly:Surface Mount Technology (SMT) assembly is a crucial step in Chinese PCB assembly, where components are mounted directly onto the PCB surface. Automated pick-and-place machines ensure accurate placement, significantly enhancing the efficiency and reliability of the assembly process.2.5 Inspection and Testing:After SMT assembly, rigorous inspection and testing procedures are undertaken to ensure the PCB's quality and functionality. Advanced testing equipment is employed to identify any defects or malfunctions, enabling timely rectification before proceeding to the next stage.2.6 Through-Hole Assembly:In cases where through-hole components are required, a selective soldering process is employed, ensuring secure and reliable connections between the through-hole components and the PCB.2.7 Quality Control and Assurance:China prioritizes stringent quality control measures at every stage of the PCB assembly process. Trained quality control personnel conduct inspections to guarantee the adherence to industry standards and customer specifications.Section 3: Advantages of China PCB Assembly3.1 Cost-effectiveness:Compared to other regions, China offers competitive manufacturing costs without compromising on quality, making it a cost-effective solution for businesses worldwide.3.2 Quick Turnaround Time:Chinese PCB assembly companies are known for their ability to deliver products within short lead times, ensuring timely market entry for customers' electronic devices.3.3 Advanced Infrastructure and Technology:China boasts a sophisticated industrial infrastructure, equipped with cutting-edge facilities, enabling efficient and precise PCB assembly processes. The application of advanced technologies ensures high-quality outputs and reliable electronic products.3.4 Customization and Flexibility:Chinese PCB assembly companies excel in providing tailored solutions to meet specific project requirements. Their flexibility in accommodating various orders, whether small-scale or large-scale, makes them an ideal choice for businesses with diverse needs.Conclusion:With their efficient and reliable PCB assembly processes, China has cemented its position as a global leader in the electronics manufacturing industry. The step-by-step guide presented in this article offers insights into the meticulous and advanced methodologies employed by Chinese companies. The cost-effectiveness, quick turnaround time, advanced infrastructure, and flexible manufacturing capabilities provided by these companies make China a preferred destination for businesses seeking high-quality PCB assembly services.

High-Quality PCB Assembly Services for Your Electronics Needs

Pcb Assembly House is a renowned electronic manufacturing service provider that has been at the forefront of delivering high-quality PCB assembly solutions to its customers for over a decade. With a strong focus on precision, efficiency, and customer satisfaction, Pcb Assembly House has earned a reputation as a trusted partner for businesses looking to outsource their electronic manufacturing needs.The company specializes in providing comprehensive PCB assembly services, including surface mount technology (SMT) assembly, through-hole assembly, and mixed technology assembly. Equipped with state-of-the-art equipment and a team of experienced technicians, Pcb Assembly House is capable of handling complex PCB assembly projects with utmost precision and attention to detail.One of the key factors that sets Pcb Assembly House apart from its competitors is its commitment to quality assurance. The company adheres to strict quality control measures at every stage of the assembly process, ensuring that each PCB assembly meets the highest industry standards. From initial design verification to final assembly inspection, Pcb Assembly House leaves no stone unturned in its pursuit of excellence.In addition to its commitment to quality, Pcb Assembly House also places a strong emphasis on efficiency and cost-effectiveness. By leveraging advanced manufacturing technologies and streamlined processes, the company is able to offer quick turnaround times without compromising on the quality of the end product. This combination of speed and precision gives Pcb Assembly House a competitive edge in the electronic manufacturing industry.Furthermore, Pcb Assembly House is dedicated to building strong and lasting relationships with its clients. The company takes a collaborative approach to project management, working closely with customers to understand their unique requirements and provide tailored solutions that meet their specific needs. This personalized approach, coupled with the company's unwavering commitment to customer satisfaction, has earned Pcb Assembly House the trust and loyalty of a diverse range of clients across various industries.In recent news, Pcb Assembly House has announced the expansion of its production capabilities to meet the growing demand for its services. The company has invested in new equipment and technology upgrades, enabling it to take on larger and more complex PCB assembly projects. This expansion is a testament to Pcb Assembly House's continued dedication to staying ahead of industry trends and exceeding customer expectations."We are thrilled to announce the expansion of our production capabilities," said [Spokesperson], [Position] at Pcb Assembly House. "This investment allows us to not only increase our capacity but also enhance our ability to deliver high-quality PCB assembly solutions to our clients. We are confident that this expansion will enable us to better serve the evolving needs of the electronic manufacturing industry."The expansion of Pcb Assembly House's production capabilities comes at a time when the demand for reliable and efficient electronic manufacturing services is on the rise. With an increasing number of businesses turning to outsourcing for their PCB assembly needs, Pcb Assembly House is well-positioned to meet this demand and continue its track record of excellence in the industry.As Pcb Assembly House looks towards the future, the company remains committed to upholding its core values of quality, efficiency, and customer satisfaction. By staying at the forefront of technological advancements and investing in its capabilities, Pcb Assembly House is poised to remain a leader in the electronic manufacturing sector for years to come.

China's Dip in Economic Growth Raises Concerns for Global Market

China Dip Faces Challenges as It Expands Into the Global MarketWith the rapid growth of the global economy, more and more Chinese companies are striving to expand their presence in the international market. One such company is China Dip, a leading manufacturer of electronic components and consumer electronics. As China Dip establishes itself as a global player, it faces several challenges in terms of competition, market penetration, and brand recognition.China Dip, headquartered in Shenzhen, China, has been a major player in the electronics industry for over two decades. The company has built a strong reputation for producing high-quality products at competitive prices, making it a trusted partner for many businesses around the world. With a wide range of electronic components and consumer electronics, China Dip has successfully served various industries, including telecommunications, automotive, and consumer technology.As the company expands into the global market, it faces stiff competition from established international players. Many of these competitors have already established strong brand recognition and customer loyalty, making it challenging for China Dip to gain a significant market share. Additionally, the company must also navigate complex international trade regulations and standards, which vary from one market to another.To address these challenges, China Dip has been actively pursuing strategic partnerships and collaborations with global technology companies. By leveraging the expertise and resources of its partners, China Dip aims to enhance its product offerings, improve its market access, and build a stronger brand presence in the global market. Furthermore, the company has been investing in research and development to innovate new products that meet the specific needs of international customers.In addition to competition and market access, China Dip also faces the challenge of brand recognition in the global market. While the company has established a strong presence in China and other Asian markets, it is relatively unknown in many parts of the world. Building brand recognition and trust among international customers requires a significant investment in marketing, advertising, and customer engagement.To overcome this challenge, China Dip has been actively promoting its brand through various channels, including trade shows, industry events, and digital marketing. The company has also been collaborating with international distributors and retailers to expand its reach and visibility in key markets. By consistently delivering high-quality products and customer service, China Dip aims to earn the trust and loyalty of customers around the world.Despite these challenges, China Dip remains optimistic about its prospects in the global market. The company's strong track record of innovation, quality, and customer satisfaction positions it as a competitive player in the international arena. With a clear focus on strategic partnerships, product innovation, and brand promotion, China Dip is well-positioned to overcome the challenges and establish itself as a global leader in the electronics industry.

Understanding the SMT Assembly Process in Factories

Smt Assembly Process Factories, a leading global electronics manufacturing company with a focus on high-quality, precision electronic components and assemblies, has continued to expand its operations and capabilities in response to the increasing demand for advanced electronics across various industries.The company has been at the forefront of providing innovative solutions for the assembly and manufacturing of surface mount technology (SMT) products. SMT is a key process in electronics manufacturing, as it allows for the creation of smaller, lighter, and more efficient electronic devices. With the increasing focus on miniaturization and the integration of advanced functionalities into electronic products, the demand for SMT assembly services has been on the rise.Smt Assembly Process Factories has established itself as a reliable and trusted partner for companies in need of high-quality SMT assembly services. The company offers a wide range of capabilities, including SMT assembly, through-hole assembly, box build assembly, and testing services. This comprehensive range of services has enabled Smt Assembly Process Factories to cater to the diverse needs of its customers, from small startups to large corporations.In addition to its advanced assembly capabilities, Smt Assembly Process Factories has also invested in state-of-the-art equipment and manufacturing facilities to ensure the highest level of precision and quality control. The company's commitment to quality is evident in its adherence to strict manufacturing standards and its implementation of industry-leading quality management systems.One of the key strengths of Smt Assembly Process Factories is its focus on innovation and continuous improvement. The company's dedicated team of engineers and technical experts are constantly exploring new technologies and processes to enhance the efficiency and capabilities of its assembly operations. This commitment to innovation has allowed Smt Assembly Process Factories to stay ahead of the competition and provide its customers with cutting-edge solutions.As part of its expansion efforts, Smt Assembly Process Factories has recently announced the opening of a new manufacturing facility in a strategic location to better serve its global customer base. This new facility is equipped with the latest SMT assembly equipment and is designed to meet the growing demand for high-volume production of electronic components and assemblies.Furthermore, Smt Assembly Process Factories has also expanded its workforce to include a team of highly skilled and experienced professionals who are dedicated to delivering exceptional service and support to customers. The company's workforce consists of individuals with diverse backgrounds and expertise, including engineers, technicians, quality control specialists, and customer service personnel.With its strong focus on quality, innovation, and customer satisfaction, Smt Assembly Process Factories is well-positioned to address the evolving needs of the electronics manufacturing industry. The company's commitment to delivering high-quality products and services has earned it a reputation as a preferred partner for businesses seeking reliable and cost-effective SMT assembly solutions.As the demand for advanced electronics continues to grow, Smt Assembly Process Factories remains committed to staying at the forefront of technological advancements and delivering value-added solutions to its customers. The company's dedication to excellence and its ability to adapt to the changing industry landscape make it a key player in the global electronics manufacturing sector.