High-Quality Wire Bonding Supplier for your Electronic Components

By:Admin

With over 20 years of experience in the industry, Al Wire Bonding Supplier has established itself as a trusted supplier of advanced wire bonding technology. The company prides itself on its ability to deliver innovative solutions that meet the ever-evolving needs of its customers.

The latest product line from Al Wire Bonding Supplier includes a range of cutting-edge wire bonding equipment and materials that are designed to offer unmatched performance and reliability. These products have been developed in response to the growing demand for more advanced wire bonding solutions, particularly in applications where precision and reliability are critical.

One of the flagship products in the new line is the Advanced Wire Bonder, a state-of-the-art machine that offers advanced features such as ultra-high-speed bonding, enhanced process control, and greater flexibility in wire bonding applications. This machine is designed to meet the needs of semiconductor manufacturers who require high-speed, high-precision bonding for their advanced semiconductor devices.

In addition to the Advanced Wire Bonder, Al Wire Bonding Supplier is also introducing a range of advanced wire bonding materials, including high-performance wire and bonding tools. These materials are specifically designed to work seamlessly with the new Advanced Wire Bonder, ensuring optimal performance and reliability in wire bonding applications.

"We are thrilled to introduce our latest product line, which represents a significant leap forward in wire bonding technology," said the spokesperson for Al Wire Bonding Supplier. "With the increasing demand for high-speed, high-precision wire bonding in the semiconductor industry, our new products are designed to help our customers stay ahead of the curve and deliver cutting-edge semiconductor devices with unmatched performance and reliability."

In addition to the new product line, Al Wire Bonding Supplier continues to offer a range of support and services to its customers, including training, technical support, and consulting services. This comprehensive approach to customer support is a key differentiator for Al Wire Bonding Supplier, as it ensures that customers receive the assistance they need to maximize the performance and reliability of their wire bonding equipment and materials.

As an established leader in the wire bonding industry, Al Wire Bonding Supplier is committed to driving innovation and delivering high-quality solutions that meet the evolving needs of its customers. With the release of its latest product line, the company is well-positioned to continue its legacy of excellence in the semiconductor industry and provide its customers with the advanced wire bonding solutions they require to succeed in a competitive market.

In conclusion, Al Wire Bonding Supplier's latest product line represents a significant advancement in wire bonding technology, offering advanced solutions that are designed to meet the increasing demand for high-speed, high-precision wire bonding in the semiconductor industry. With its extensive experience and commitment to innovation, Al Wire Bonding Supplier continues to be a trusted partner for semiconductor manufacturers seeking reliable and high-performance wire bonding solutions.

Company News & Blog

Top Welding Factories to Meet Your Industrial Needs

Welding Factories in need of a reliable and efficient welding solution can now turn to the innovative products and services offered by {}.{} is a leading provider of welding equipment and solutions for a wide range of industries and applications. With a strong commitment to quality, innovation, and customer satisfaction, the company has established a solid reputation as a trusted partner for welding factories around the world.One of the primary reasons why welding factories choose {} as their preferred welding solution provider is the company's extensive range of high-quality products. From welding machines and equipment to consumables, accessories, and safety gear, {} offers a comprehensive selection of products that are designed to meet the diverse needs of welding factories.In addition to its impressive product range, {} also prides itself on its ability to provide customized solutions for welding factories. The company's team of experienced engineers and technical specialists works closely with each client to understand their specific requirements and develop tailored solutions that meet their needs. This personalized approach sets {} apart from other welding equipment providers and ensures that clients receive the best possible solution for their welding applications.Moreover, {} is committed to staying at the forefront of welding technology and innovation. The company invests heavily in research and development to continuously improve its products and develop new, cutting-edge solutions for the welding industry. By staying ahead of the curve, {} ensures that its clients have access to the latest and most advanced welding technologies, helping them improve efficiency, productivity, and quality in their welding operations.In addition to its product offerings, {} is also known for its exceptional customer service and support. The company's team of dedicated professionals is always available to provide assistance, guidance, and technical support to welding factories. Whether it's helping clients select the right equipment, addressing technical issues, or providing training and education, {} is committed to being a reliable and responsive partner for its clients.Furthermore, {} is deeply committed to sustainability and environmental responsibility. The company recognizes the importance of minimizing its environmental impact and promoting sustainable practices within the welding industry. As such, {} has implemented various initiatives to reduce energy consumption, waste generation, and emissions, while also developing eco-friendly products and solutions for its clients.With its comprehensive product range, custom solutions, commitment to innovation, exceptional customer service, and sustainable practices, {} has firmly established itself as a global leader in the welding industry. Welding factories looking for a reliable and efficient welding solution can trust {} to meet their needs and help them achieve their welding objectives.To learn more about {} and its products and services, visit the company's website or contact their team directly for personalized assistance. With its unwavering dedication to quality, innovation, and customer satisfaction, {} is the ideal partner for welding factories seeking a trusted and reliable welding solution provider.

Gold Ribbon Bonding Supplier: Meeting Demands for Quality Bonding Services

[Company Introduction][Company Name] is a leading provider of innovative bonding solutions in the electronics industry. With a focus on research and development, our company is committed to supplying high-quality gold ribbon bonding products to manufacturers worldwide. As a trusted partner, we strive to meet the ever-evolving demands of our customers, enabling them to enhance the performance and reliability of their electronic devices.Our state-of-the-art manufacturing facilities, coupled with an experienced team of engineers and technicians, position us at the forefront of the industry. We take pride in our ability to deliver customized solutions tailored to our customers' specific requirements. Whether it is bonding wires for semiconductors, LED packages, or any other electronic component, our gold ribbon bonding products are designed to provide exceptional conductivity and stability, ensuring the longevity of electronic devices in diverse applications.With a strong emphasis on technological innovation, we constantly invest in research and development activities. Our dedicated team of engineers collaborates with industry experts and academic institutions to explore novel bonding techniques and materials. This commitment to innovation drives us to continuously improve our products and offer advanced bonding solutions that empower our customers to excel in a highly competitive market.In addition to our dedication to quality and innovation, we place great importance on sustainability and environmental responsibility. Our manufacturing processes adhere to stringent environmental regulations and best practices, striving to minimize the impact on the planet while maintaining the highest standards of product performance. We are committed to promoting sustainability across the industry and actively seek partnerships with like-minded organizations to drive positive change.[News][Date], [Company Name] announced its latest breakthrough in the field of gold ribbon bonding, revolutionizing the electronics industry with its advanced bonding products and techniques. The company's continued commitment to technological innovation has positioned it as a leading supplier of gold ribbon bonding solutions, catering to the diverse needs of manufacturers worldwide.The new range of gold ribbon bonding products introduced by [Company Name] offers improved conductivity, reliability, and ease of use. With enhanced performance characteristics, manufacturers can now improve the efficiency and functionality of their electronic devices, meeting the ever-increasing demands of consumers in today's digital age.One of the key highlights of the new product line is its compatibility with a wide range of electronic components. Whether it is bonding wires for semiconductors, LED packages, or other critical components, [Company Name]'s gold ribbon bonding products ensure seamless integration, providing manufacturers with a versatile solution suitable for various applications.The advanced bonding techniques developed by [Company Name] have also been met with great enthusiasm within the industry. By leveraging state-of-the-art manufacturing processes and materials, the company has significantly increased the bond strength and durability of its gold ribbon bonding products. This breakthrough not only enhances the lifespan of electronic devices but also improves their resistance to environmental factors such as temperature fluctuations and mechanical stress.Furthermore, [Company Name]'s commitment to sustainability has resulted in the development of eco-friendly gold ribbon bonding solutions. These products adhere to the highest environmental standards, without compromising on performance or reliability. As electronic waste continues to be a growing concern, [Company Name] aims to provide manufacturers with innovative bonding solutions that minimize environmental impact and promote a more sustainable electronics industry.As a leading bonding supplier, [Company Name]'s dedication to customer satisfaction remains unparalleled. The company's global network of experts ensures comprehensive technical support and reliable customer service, aiding manufacturers in every step of their bonding processes. By fostering long-term partnerships with clients, [Company Name] continually adapts its solutions to align with the evolving needs of the electronics industry.With its latest advancements in gold ribbon bonding, [Company Name] sets a new benchmark for excellence in the electronics industry. By combining innovation, sustainability, and customer-centricity, the company reaffirms its position as a trusted partner for manufacturers seeking cutting-edge bonding solutions. As the industry continues to evolve, [Company Name] remains committed to pushing the boundaries of gold ribbon bonding technology, empowering manufacturers to deliver high-performance electronic devices that shape the world we live in.

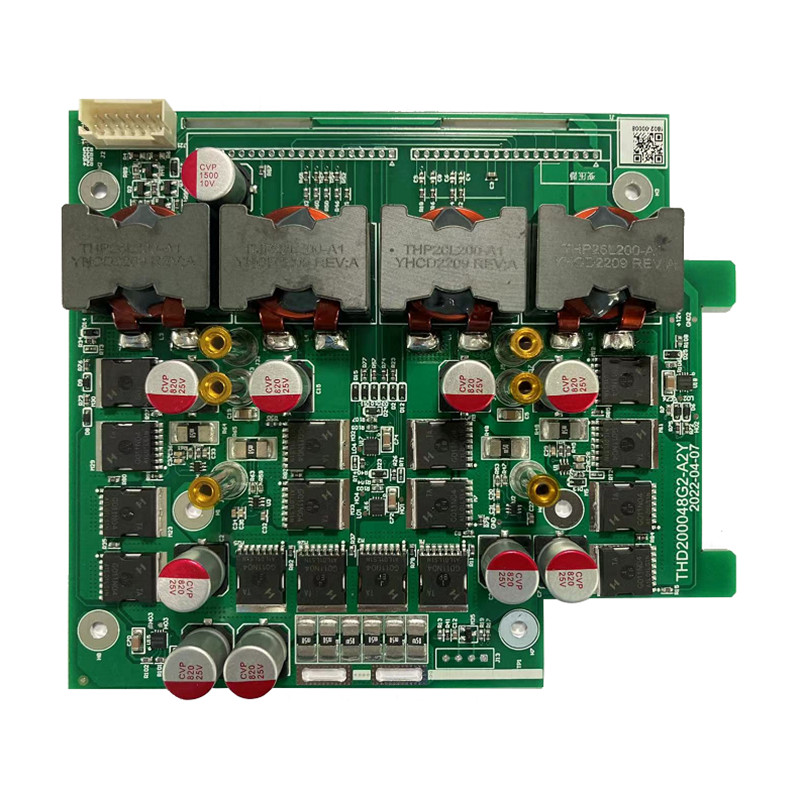

Complete Guide to PCB Assembly in a Factory Setting

Pcb Assembly Full Form Factory (PAFFF), a leading manufacturer in the electronics industry, is dedicated to providing high-quality PCB assembly services to its customers. With a state-of-the-art facility and a team of experienced professionals, PAFFF has established itself as a reliable and trusted partner for companies looking to outsource their PCB assembly needs.The company specializes in providing turnkey PCB assembly solutions, offering a full range of services including PCB fabrication, component sourcing, PCB assembly, testing, and packaging. PAFFF’s expertise in PCB assembly allows its customers to streamline their production processes and reduce time-to-market for their products.PAFFF’s commitment to quality is evident in its adherence to industry standards and regulations. The company’s facility is equipped with advanced equipment and technology to ensure precision and accuracy in every step of the assembly process. From automated pick-and-place machines to advanced inspection tools, PAFFF integrates the latest innovations to deliver superior quality PCB assemblies.Furthermore, PAFFF is dedicated to maintaining a high level of customer satisfaction through its responsive and flexible approach. The company works closely with its clients to understand their specific requirements and tailor its services to meet their needs. Whether it’s a prototype build or a full production run, PAFFF is committed to delivering reliable and cost-effective PCB assembly solutions.In addition to its manufacturing capabilities, PAFFF places a strong emphasis on sustainability and environmental responsibility. The company has implemented eco-friendly practices in its operations, including waste reduction, energy efficiency, and proper disposal of hazardous materials. PAFFF’s commitment to sustainability reflects its dedication to ethical business practices and corporate social responsibility.With a proven track record of delivering high-quality PCB assemblies, PAFFF has become a preferred partner for companies across various industries, including automotive, aerospace, telecommunications, consumer electronics, and medical devices. The company’s broad expertise, combined with its commitment to excellence, has positioned it as a trusted leader in the PCB assembly industry.As part of its continuous growth and expansion efforts, PAFFF recently announced plans to invest in the latest manufacturing technologies to further enhance its capabilities. The company aims to increase its production capacity, improve efficiency, and meet the evolving needs of its customers.“We are excited to embark on this new phase of expansion, as we continue to strengthen our position as a leading PCB assembly provider,” said the spokesperson for PAFFF. “Our investment in advanced technologies will allow us to better serve our customers and adapt to the rapidly changing demands of the industry.”PAFFF’s dedication to excellence, commitment to sustainability, and focus on customer satisfaction have set it apart as a top-tier PCB assembly provider. As the company continues to grow and innovate, it remains poised to meet the evolving needs of the electronics industry and exceed the expectations of its customers.

Latest Developments in the Electronics Manufacturing Industry Revealed

[News Title]SMT Electronics Manufacturing Company Streamlines Production Processes for Enhanced Manufacturing Efficiency[News Body][City name], [Date] - SMT Electronics Manufacturing, a leading company in the electronics manufacturing industry, is revolutionizing the way electronics are produced. By combining state-of-the-art technology with a relentless focus on innovation and efficiency, the company is setting new industry standards.SMT Electronics Manufacturing has been at the forefront of electronics manufacturing for over two decades, consistently delivering high-quality products to global customers. With a diverse portfolio of clients ranging from small startups to multinational corporations, the company has established itself as a trusted partner in the industry.By leveraging its extensive experience and expertise, SMT Electronics Manufacturing has become synonymous with cutting-edge technology and efficient manufacturing processes. The company's commitment to innovation has propelled it to the forefront of the electronics manufacturing sector, with a reputation for delivering products that meet and exceed customer expectations.One of the key factors behind SMT Electronics Manufacturing's success is its relentless pursuit of manufacturing efficiency. Realizing the need to optimize production processes, the company has invested heavily in advanced technology and automation systems. By embracing the latest developments in robotics, artificial intelligence, and data analytics, SMT Electronics Manufacturing has streamlined its operations, resulting in increased productivity and reduced costs.SMT Electronics Manufacturing's state-of-the-art factory is a testament to its commitment to excellence. Equipped with cutting-edge machinery and production lines, the facility operates at peak efficiency, allowing the company to meet customer demands with ease. From the initial design phase to the final product assembly, every step of the manufacturing process is closely monitored and optimized to ensure precision and quality.The company's dedication to quality is further exemplified by its stringent quality control measures. SMT Electronics Manufacturing adheres to industry-leading standards and certifications, ensuring that every product leaving its facility is of the highest quality. By conducting regular audits and inspections, the company maintains its commitment to delivering excellence in every aspect of its operations.Sustainability and environmental responsibility are also key pillars of SMT Electronics Manufacturing's business philosophy. Recognizing the importance of minimizing its ecological footprint, the company has implemented various initiatives to promote eco-friendly practices. From utilizing energy-efficient machinery to recycling waste materials, SMT Electronics Manufacturing is actively working towards a greener future.In addition to its commitment to manufacturing excellence, SMT Electronics Manufacturing also places a strong emphasis on customer satisfaction. The company's dedicated customer service team works closely with clients to understand their specific requirements and provide tailored solutions. By fostering long-term partnerships and responsive communication, SMT Electronics Manufacturing has cultivated a loyal customer base that values its commitment to quality and reliability.Looking towards the future, SMT Electronics Manufacturing aims to continue setting new benchmarks in the electronics manufacturing industry. By investing in research and development and staying ahead of the latest technological advancements, the company endeavors to remain at the forefront of innovation. Moreover, SMT Electronics Manufacturing plans to expand its global reach and forge new partnerships that will further solidify its position as a leader in the industry.About SMT Electronics Manufacturing:SMT Electronics Manufacturing is a renowned electronics manufacturing company based in [City, Country]. With a strong emphasis on innovation, efficiency, and customer satisfaction, the company has established itself as a trusted partner for clients worldwide. With a wide range of services including design, production, and quality control, SMT Electronics Manufacturing delivers cutting-edge products that meet and exceed industry standards.For more information, please visit [Company website].[PR Contact][Contact Name][Position][Email][Phone Number]

Circuit Card Assembly Factory: A Hub of Advanced Electronics Manufacturing

[Company Name] Opens State-of-the-Art Circuit Card Assembly Factory[City, State] - [Company Name], a leading provider of cutting-edge technology solutions, has recently unveiled its new state-of-the-art circuit card assembly factory in [City, State]. The facility marks a significant milestone in the company's expansion plans and is set to revolutionize the production and assembly of circuit cards.Spanning over [number] square feet, the newly built circuit card assembly factory is equipped with the latest cutting-edge technologies and advanced machinery. With a production capacity of [number] circuit cards per day, the facility is designed to meet the increasing demand for high-quality circuit card assembly solutions in various industries, including automotive, telecommunications, aerospace, and consumer electronics.[Company Name] has always been at the forefront of innovation and aims to deliver superior products that exceed customer expectations. The new factory is a testament to the company's commitment to excellence and its persistent efforts to provide best-in-class circuit card assembly services.The facility boasts a highly trained and skilled workforce, consisting of engineers, technicians, and quality control professionals who ensure the seamless assembly of circuit cards. Equipped with expertise in the latest manufacturing techniques and utilizing advanced equipment, the team guarantees the highest level of quality and reliability.The circuit card assembly process in the factory follows a meticulous and robust procedure to ensure maximum efficiency and accuracy. From component placement and solder paste printing to inspection and testing, each stage is executed with precision and attention to detail. The factory adheres to stringent quality standards and complies with all applicable industry regulations to deliver products that are unmatched in their quality and performance.By investing in state-of-the-art machinery and automated systems, [Company Name] can achieve enhanced precision, increased production speed, and reduced costs. The factory is equipped with cutting-edge robotics and computerized systems that optimize the assembly process, enabling quicker turnaround times without compromising on quality.One of the key features of the facility is its commitment to environmental sustainability. [Company Name] has incorporated green practices throughout the factory, focusing on minimizing waste, conserving energy, and adopting eco-friendly manufacturing processes. The company's dedication to sustainability aligns with its vision to create a greener future while providing innovative circuit card assembly solutions to its customers.The inauguration of the circuit card assembly factory reinforces [Company Name]'s position as a trusted partner for businesses looking for high-quality circuit cards. With the capacity to scale production based on customer requirements, the company is well-positioned to cater to the growing market demand for reliable and technologically advanced circuit cards.The new factory also signifies the company's commitment to local job creation and economic growth. By setting up the facility in [City, State], [Company Name] has created numerous employment opportunities, contributing to the growth of the local economy and fostering innovation within the region.As [Company Name] continues its expansion plans, the circuit card assembly factory empowers the company to further strengthen its market position and expand its reach globally. The facility is poised to drive innovation, provide exceptional products, and deliver unparalleled customer experiences.About [Company Name]:[Company Name] is a leading global provider of cutting-edge technology solutions for various industries. With a focus on innovation, quality, and customer satisfaction, the company is committed to delivering superior products and services that shape the future. [Company Name] operates in [number] countries and caters to a diverse range of clients, including multinational corporations and small businesses.

High-Quality Wire Bonding Supplier for your Electronic Components

Al Wire Bonding Supplier, a leading provider of advanced wire bonding solutions, has announced the release of their latest product line designed to meet the increasing demand for high-quality wire bonding in the semiconductor industry.With over 20 years of experience in the industry, Al Wire Bonding Supplier has established itself as a trusted supplier of advanced wire bonding technology. The company prides itself on its ability to deliver innovative solutions that meet the ever-evolving needs of its customers.The latest product line from Al Wire Bonding Supplier includes a range of cutting-edge wire bonding equipment and materials that are designed to offer unmatched performance and reliability. These products have been developed in response to the growing demand for more advanced wire bonding solutions, particularly in applications where precision and reliability are critical.One of the flagship products in the new line is the Advanced Wire Bonder, a state-of-the-art machine that offers advanced features such as ultra-high-speed bonding, enhanced process control, and greater flexibility in wire bonding applications. This machine is designed to meet the needs of semiconductor manufacturers who require high-speed, high-precision bonding for their advanced semiconductor devices.In addition to the Advanced Wire Bonder, Al Wire Bonding Supplier is also introducing a range of advanced wire bonding materials, including high-performance wire and bonding tools. These materials are specifically designed to work seamlessly with the new Advanced Wire Bonder, ensuring optimal performance and reliability in wire bonding applications."We are thrilled to introduce our latest product line, which represents a significant leap forward in wire bonding technology," said the spokesperson for Al Wire Bonding Supplier. "With the increasing demand for high-speed, high-precision wire bonding in the semiconductor industry, our new products are designed to help our customers stay ahead of the curve and deliver cutting-edge semiconductor devices with unmatched performance and reliability."In addition to the new product line, Al Wire Bonding Supplier continues to offer a range of support and services to its customers, including training, technical support, and consulting services. This comprehensive approach to customer support is a key differentiator for Al Wire Bonding Supplier, as it ensures that customers receive the assistance they need to maximize the performance and reliability of their wire bonding equipment and materials.As an established leader in the wire bonding industry, Al Wire Bonding Supplier is committed to driving innovation and delivering high-quality solutions that meet the evolving needs of its customers. With the release of its latest product line, the company is well-positioned to continue its legacy of excellence in the semiconductor industry and provide its customers with the advanced wire bonding solutions they require to succeed in a competitive market.In conclusion, Al Wire Bonding Supplier's latest product line represents a significant advancement in wire bonding technology, offering advanced solutions that are designed to meet the increasing demand for high-speed, high-precision wire bonding in the semiconductor industry. With its extensive experience and commitment to innovation, Al Wire Bonding Supplier continues to be a trusted partner for semiconductor manufacturers seeking reliable and high-performance wire bonding solutions.

Top Tips for Designing a PCB Prototype

Pcb Prototype Design Factory, a leading provider of innovative PCB prototype design and manufacturing services, has been making waves in the electronics industry. With its state-of-the-art facilities and experienced team, the company has established itself as a go-to destination for businesses looking to bring their electronic products to life.Established in [year], Pcb Prototype Design Factory has quickly risen to prominence, thanks to its commitment to delivering high-quality, cost-effective solutions to its clients. The company specializes in providing comprehensive PCB prototype design and manufacturing services, catering to a wide range of industries, including aerospace, automotive, consumer electronics, telecommunications, and more.What sets Pcb Prototype Design Factory apart from its competitors is its relentless focus on innovation and customer satisfaction. The company has invested heavily in cutting-edge technology and equipment, enabling it to stay ahead of the curve and deliver superior products to its clients. Moreover, Pcb Prototype Design Factory employs a team of highly skilled engineers and designers who work tirelessly to bring their clients' visions to life.Furthermore, Pcb Prototype Design Factory is renowned for its fast turnaround times and competitive pricing. The company understands the importance of speed and efficiency in today's fast-paced business environment, and it has honed its processes to ensure that clients receive their prototypes in a timely manner, without sacrificing quality. Additionally, Pcb Prototype Design Factory prides itself on its transparent pricing structure, ensuring that clients receive exceptional value for their investment.In addition to its technical prowess, Pcb Prototype Design Factory places a strong emphasis on customer service. The company’s team of dedicated professionals goes above and beyond to provide personalized support and guidance to its clients throughout the design and manufacturing process. From the initial concept development to the final product delivery, Pcb Prototype Design Factory is committed to ensuring that its clients' needs are met with the utmost care and attention.Pcb Prototype Design Factory has also been steadfast in its commitment to sustainability and environmental responsibility. The company adheres to strict environmental standards and consistently seeks out ways to minimize its ecological footprint. By utilizing eco-friendly materials and processes, Pcb Prototype Design Factory aims to be a force for good in the electronics industry, demonstrating its dedication to a cleaner, greener future.Looking ahead, Pcb Prototype Design Factory is poised for continued success and growth. The company’s unwavering dedication to excellence, coupled with its innovative approach to PCB prototype design and manufacturing, sets it apart as a trailblazer in the industry. Pcb Prototype Design Factory remains committed to pushing the boundaries of what is possible, and it looks forward to continuing to serve as a trusted partner for businesses seeking top-tier PCB prototype solutions.With its proven track record, dedication to quality and innovation, and unwavering commitment to customer satisfaction, Pcb Prototype Design Factory is well-positioned to remain a dominant force in the electronics industry for years to come. If you are in need of cutting-edge PCB prototype design and manufacturing services, Pcb Prototype Design Factory is the partner of choice.

Pioneering PCB Chip-On-Board Factory Streamlines Electronics Manufacturing Process

Title: PCB Chip-On-Board Factory Pioneers Advanced Manufacturing TechniquesIntroduction:In the world of electronics manufacturing, PCB (Printed Circuit Board) production is a crucial component that enables the smooth functioning of various electronic devices. One leading player in the field, a cutting-edge and innovative PCB Chip-On-Board factory, is revolutionizing the industry by combining advanced manufacturing techniques with top-notch expertise. With a commitment to quality and excellence, this factory has gained a stellar reputation for producing high-performance PCBs used in diverse industries. Let's delve into the company's profile and explore their approach to achieving manufacturing excellence.Company Profile:The PCB Chip-On-Board factory's core foundations are built upon years of experience and expertise in PCB manufacturing. Founded by a team of industry veterans, the factory has evolved into a top player known for its comprehensive product range, advanced technology, and exceptional customer service. With a state-of-the-art production facility equipped with cutting-edge machinery, the factory has achieved unmatched operational efficiency while ensuring compliance with international quality standards.Advanced Manufacturing Techniques:The PCB Chip-On-Board factory prides itself on its commitment to embracing the latest manufacturing techniques to meet the ever-evolving demands of the electronics industry. Utilizing advanced machinery and processes, the factory employs a combination of automation, machine learning, and artificial intelligence to streamline operations and minimize errors.1. Precision Placement Technology: The factory employs high-precision placement machines that can handle miniaturized components with utmost accuracy. This technology allows for the creation of densely packed PCBs, enabling circuitry designs that are both space-efficient and high-performing.2. Automated Optical Inspection (AOI): To ensure the highest quality standards, the factory employs AOI systems that use sophisticated cameras and intelligent algorithms to detect any defects or abnormalities during the manufacturing process. This advanced inspection technique guarantees that only flawless PCBs make their way to the customers.3. Surface Mount Technology (SMT): The factory excels in producing PCBs using surface mount technology, which involves mounting components directly onto the PCB's surface, eliminating the need for separate wiring. This technique enables higher component density, better electrical performance, and reduced assembly costs.4. Environmental Sustainability: The factory places immense emphasis on environmental sustainability by implementing eco-friendly manufacturing practices. They employ lead-free soldering techniques, utilize energy-efficient equipment, and promote recycling and responsible waste disposal methodologies. By reducing their carbon footprint, the factory demonstrates its commitment to preserving the environment.Customer-focused Approach:The PCB Chip-On-Board factory is renowned for its strong customer-centric approach. The highly skilled team consistently works closely with clients to understand their specific requirements and provide tailored solutions. Whether for industries such as automotive, consumer electronics, or telecommunications, the factory's engineers and technicians offer expertise and support throughout the product development process.Research and Development:Being at the forefront of technological advancements, the factory invests extensively in research and development to continually improve its products and processes. The team collaborates closely with clients, academia, and industry experts to explore emerging trends in design, materials, and testing methodologies. Through this commitment to innovation, the factory ensures it stays ahead in a competitive market.Conclusion:The PCB Chip-On-Board factory sets a benchmark in the electronics manufacturing industry by seamlessly integrating cutting-edge technologies with extensive expertise. Its commitment to advanced manufacturing techniques, environmental sustainability, and customer-focused approach has earned the factory a reputable standing in the market. With an unwavering dedication to quality and continual improvement, the factory is primed to remain a leader in producing high-performance PCBs for an array of industries worldwide.

Automated PCB Assembly Factory: Revolutionizing Electronics Manufacturing

[Company Introduction]Established in 2005, [company name] is a leading provider of innovative electronic manufacturing services. With a focus on cutting-edge technology and a commitment to quality and customer satisfaction, [company name] has become a trusted partner for businesses looking to outsource their electronic manufacturing needs. With state-of-the-art facilities and a team of skilled professionals, [company name] has positioned itself as a pioneer in the industry, offering a wide range of services including PCB assembly, box build assembly, cable assembly, and testing. The company's dedication to continuous improvement and investment in the latest equipment has allowed it to stay at the forefront of the ever-evolving electronics industry.[Automated PCB Assembly Factory][Company name] is proud to announce the opening of its new automated PCB assembly factory. This state-of-the-art facility is equipped with the latest in robotic technology, allowing for a streamlined and efficient production process. With the ability to handle high-volume orders while maintaining precision and quality, the automated PCB assembly factory represents a significant milestone for [company name] and its commitment to meeting the needs of its customers.The introduction of the automated PCB assembly factory comes as a response to the growing demand for faster and more reliable PCB assembly services. With the increasing complexity of electronic devices and the need for quicker time-to-market, the new facility will allow [company name] to offer its clients a competitive edge in the industry.The automated PCB assembly factory boasts cutting-edge robotic assembly lines that are capable of handling a wide range of PCB types and sizes. The integration of robotic technology ensures consistent and precise soldering, component placement, and testing, leading to a higher level of product quality and reliability.In addition to the advanced robotics, the factory is also equipped with a sophisticated quality control system that monitors every stage of the assembly process, ensuring that all products meet the highest standards. This commitment to quality is a cornerstone of [company name]'s business philosophy and is a key factor in its success in the industry.Moreover, the new facility incorporates the latest advancements in smart manufacturing and data analytics, allowing for real-time monitoring of production metrics and performance. This enables [company name] to continuously optimize its processes and respond swiftly to changing market demands, ensuring that customers receive the most efficient and cost-effective solutions.The automated PCB assembly factory also reflects [company name]'s dedication to environmental sustainability. The facility has been designed to minimize energy consumption and reduce waste, in line with the company's commitment to responsible manufacturing practices.By leveraging the capabilities of its new automated PCB assembly factory, [company name] is well-positioned to continue its mission of providing exceptional electronic manufacturing services to its clients. With increased efficiency, productivity, and quality assurance, the company aims to drive innovation and value for its customers in an ever-evolving industry.The opening of the automated PCB assembly factory is a testament to [company name]'s ongoing investment in technology and its unwavering dedication to meeting the needs of its customers. As the company continues to grow and expand its capabilities, it remains committed to delivering the highest quality electronic manufacturing services and remaining a trusted partner for businesses worldwide.

High-Quality PCB Assembly Testing Supplier for Your Business Needs

In today's fast-paced and technology-driven world, the demand for high-quality printed circuit board (PCB) assembly testing suppliers is on the rise. With the increasing complexity of electronic products, it is crucial for companies to have reliable and efficient PCB assembly testing solutions in place. This is where a leading PCB assembly testing supplier comes into play.When it comes to reliable and efficient PCB assembly testing, one company that stands out among the rest is {}. With a proven track record of delivering top-notch PCB assembly testing solutions, {} has established itself as a trusted partner for companies looking to ensure the quality and reliability of their electronic products.{} is a leading provider of PCB assembly testing solutions, offering a comprehensive range of services to meet the diverse needs of its clients. The company's state-of-the-art facilities and cutting-edge technology allow them to perform a wide range of tests with precision and accuracy, ensuring that every product meets the highest quality standards.One of the key strengths of {} lies in its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of the curve and provide its clients with the most advanced PCB assembly testing solutions available. This dedication to innovation has enabled {} to develop cutting-edge testing techniques and methodologies, setting new benchmarks for quality and reliability in the industry.In addition to its technological prowess, {} is also known for its exceptional customer service. The company takes a customer-centric approach to business, working closely with its clients to understand their specific needs and deliver tailored solutions that meet or exceed their expectations. Whether it's a small-scale project or a large-scale production run, {} is dedicated to providing the highest level of service and support at every step of the process.Furthermore, {} maintains a strong focus on quality and compliance, adhering to the strictest industry standards and regulations. The company's commitment to excellence has earned it a reputation for reliability and trustworthiness, making {} the go-to choice for companies looking for a PCB assembly testing supplier they can rely on.With a solid reputation for quality, innovation, and customer service, it's no wonder that {} is a trusted name in the PCB assembly testing industry. As the demand for high-quality PCB assembly testing solutions continues to grow, {} remains at the forefront, delivering cutting-edge services and exceeding client expectations.In conclusion, a reliable and efficient PCB assembly testing supplier is crucial for companies looking to ensure the quality and reliability of their electronic products. With its state-of-the-art facilities, commitment to innovation, exceptional customer service, and unwavering dedication to quality and compliance, {} has solidified its position as a leader in the PCB assembly testing industry. As the company continues to push the boundaries of excellence, it is well-positioned to meet the evolving needs of its clients and maintain its reputation as a trusted partner for high-quality PCB assembly testing solutions.