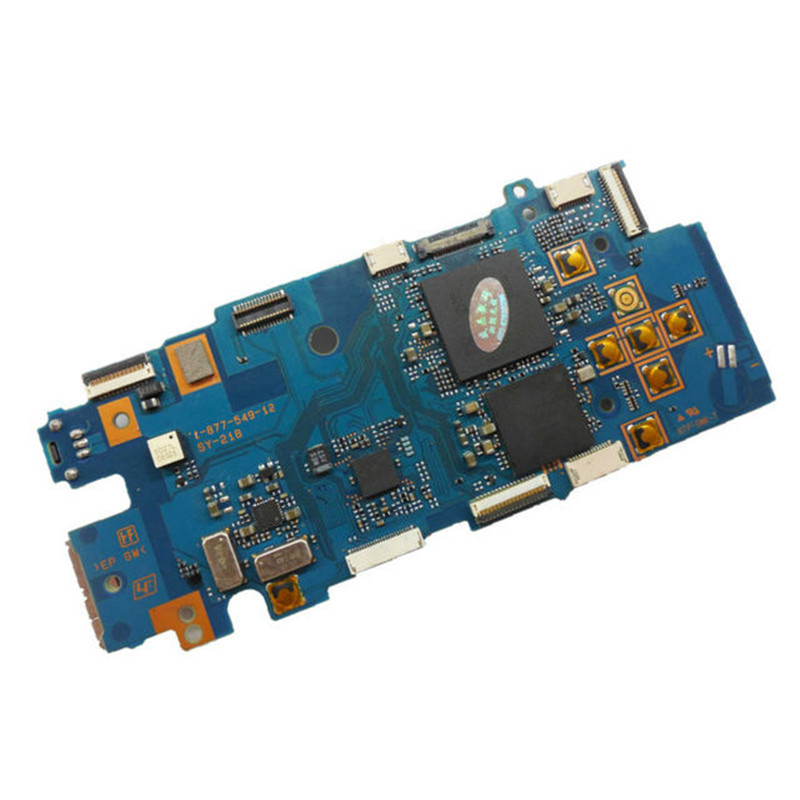

Quality Small Batch PCB Assembly Services at Competitive Prices

By:Admin

With a state-of-the-art facility equipped with the latest in PCB assembly technology, [Company Name] is able to offer a wide range of services to meet the needs of their customers. From prototype assembly to small batch production runs, they have the capabilities to handle projects of any size and complexity. Their team of experienced engineers and technicians work closely with clients to ensure that their unique requirements are met with precision and efficiency.

One of the key strengths of [Company Name] is their small batch PCB assembly services. They understand that not every project requires large production runs, and are able to offer cost-effective solutions tailored to the specific needs of their clients. This flexibility has made them a go-to partner for businesses looking to bring niche products to market, as well as those who are testing new designs and concepts.

In addition to their assembly services, [Company Name] also offers a range of other capabilities to support their clients throughout the product development process. These include PCB design, component sourcing, DFM (Design for Manufacturability) analysis, and testing services. By providing a comprehensive suite of solutions, they are able to streamline the production process and save their clients time and money.

[Company Name] is committed to maintaining the highest standards of quality and reliability in all of their services. They are ISO 9001 certified, and take pride in their rigorous quality control processes that ensure that every product that leaves their facility meets the strictest of standards. Their dedication to quality has earned them a reputation as a trusted partner for businesses in a wide range of industries, including medical, aerospace, automotive, and consumer electronics.

The team at [Company Name] is also dedicated to staying at the forefront of industry advancements, and regularly invests in new technologies and equipment to enhance their capabilities. This commitment to innovation has allowed them to continuously improve their services and offer their clients the most advanced solutions available.

With a proven track record of success and a commitment to excellence, [Company Name] has become a go-to partner for businesses looking for small batch PCB assembly services. Their combination of cutting-edge technology, experienced team, and unwavering commitment to quality has set them apart in the industry, and made them a trusted partner for businesses of all sizes.

As the demand for small batch PCB assembly services continues to grow, [Company Name] is well-positioned to meet the needs of businesses looking to bring innovative electronic products to market. With their focus on customer service, quality, and innovation, they are poised to remain a leader in the industry for years to come.

In conclusion, [Company Name] is a company that has solidified its position as a leading provider of small batch PCB assembly services, and their dedication to excellence and customer satisfaction has made them a trusted partner for businesses in a wide range of industries. With a commitment to quality, innovation, and flexibility, they are well-equipped to meet the evolving needs of their clients and remain at the forefront of the industry.

Company News & Blog

Top Factories for Prototype PCB Design: Everything You Need to Know

Prototype PCB Design Factories, a cutting-edge company specializing in the production of printed circuit boards (PCBs), has recently expanded its operations to meet the growing demand for advanced PCB designs in the technology industry. With an impressive track record of delivering high-quality PCBs to a wide range of clients, Prototype PCB Design Factories has positioned itself as a leading player in the PCB manufacturing industry.Established in (insert year), Prototype PCB Design Factories has steadily grown its presence in the market by offering innovative solutions and state-of-the-art manufacturing capabilities. The company has a dedicated team of highly skilled engineers and technicians who are committed to delivering superior quality PCBs that meet the unique specifications and requirements of each client.One of the key factors that sets Prototype PCB Design Factories apart from the competition is its advanced design and manufacturing capabilities. The company has invested heavily in state-of-the-art equipment and technology to ensure that it can produce PCBs that meet the highest industry standards for quality and reliability. This commitment to innovation has enabled Prototype PCB Design Factories to stay ahead of the curve in a rapidly evolving industry.In a recent statement, (company spokesperson) highlighted the importance of staying on the cutting edge of technology in order to meet the needs of the company's diverse client base. "With the constant advancements in technology, the demand for more sophisticated PCB designs continues to grow," (spokesperson) said. "At Prototype PCB Design Factories, we are committed to investing in the latest technology and equipment to ensure that we can meet the evolving needs of our clients and continue to deliver superior quality PCBs."The expansion of Prototype PCB Design Factories' operations comes at a time when the demand for advanced PCB designs is at an all-time high. As the technology industry continues to innovate at a rapid pace, companies are increasingly turning to manufacturers like Prototype PCB Design Factories to provide them with the cutting-edge PCBs they need to power their products and applications.One of the key reasons for Prototype PCB Design Factories' continued success is its commitment to providing exceptional customer service. The company understands that each client has unique needs and works closely with them to develop customized solutions that meet their specific requirements. This dedication to customer satisfaction has earned Prototype PCB Design Factories a strong reputation in the industry, with many clients choosing to partner with the company for their PCB manufacturing needs time and time again.Looking ahead, Prototype PCB Design Factories is poised to continue its upward trajectory in the industry. With its focus on innovation, quality, and customer service, the company is well-positioned to meet the evolving demands of the technology industry and remain a leader in the PCB manufacturing sector.As the demand for advanced PCB designs continues to grow, Prototype PCB Design Factories is ready to meet the needs of its clients with its state-of-the-art manufacturing capabilities, innovative solutions, and commitment to excellence. With a strong track record of delivering high-quality PCBs to a diverse range of clients, the company is well-equipped to stay at the forefront of the industry for years to come.

Boost Your Electronics Manufacturing with High-Quality PCB Assembly Services

[Publication Name] – [Date]PCB Assembly Firm Enhances Production Capabilities to Meet Growing Demand[City, State] – With the increasing demand for advanced PCB assembly services, [PCB Assembly Firm] has expanded its production capabilities, allowing the company to better cater to the needs of its diverse clientele. As a leading provider of high-quality and reliable PCB assembly solutions, [PCB Assembly Firm] has established its position within the industry by combining cutting-edge technology, a skilled workforce, and a commitment to exceptional customer service.[PCB Assembly Firm] specializes in offering end-to-end PCB assembly services, including prototyping, component sourcing, assembly, testing, and quality control. Whether it's a small-scale project or a large-scale production run, the firm's state-of-the-art facility and experienced team ensure that each assembly meets the highest industry standards.Based in [City, State], [PCB Assembly Firm] has been serving a wide range of industries, including automotive, telecommunications, medical devices, consumer electronics, and more. The company's ability to adapt to evolving market trends and regulatory requirements has been instrumental in maintaining its strong clientele base and establishing itself as a trusted partner for businesses seeking reliable PCB assembly services.One of the primary reasons behind [PCB Assembly Firm]'s success is its continuous investment in advanced manufacturing equipment and technology. The firm recently upgraded its production facility, doubling its capacity and incorporating cutting-edge machinery. By doing so, [PCB Assembly Firm] ensures it remains at the forefront of technological advancements, guaranteeing the efficient and precise assembly of complex PCBs.The company's investment in new equipment has allowed it to meet the increased demand for high-density assemblies, incorporating smaller components while improving overall performance. As the industry continues to move towards miniaturization and improved functionality, [PCB Assembly Firm] is well-equipped to fulfill the evolving needs of its customers."We understand that our clients require not only high-quality PCB assembly services, but also timely deliveries," said [Spokesperson], the spokesperson for [PCB Assembly Firm]. "Our latest expansion enables us to maintain our commitment to quick turnaround times without compromising on quality. We take pride in our ability to fulfill our clients' assembly needs, no matter how complex."In addition to its investments in equipment, [PCB Assembly Firm] places significant importance on the expertise and skillset of its workforce. The company employs a team of highly trained technicians and engineers who are well-versed in the latest industry standards and best practices. This team is responsible for overseeing every step of the assembly process, ensuring that each product meets the stringent quality requirements expected by [PCB Assembly Firm]'s clients.Furthermore, [PCB Assembly Firm] is dedicated to unparalleled customer service. The company works closely with its clients, offering tailored solutions and project consultations to ensure that their specific requirements are met. By taking a collaborative approach, [PCB Assembly Firm] establishes long-term relationships with its clients, fostering a sense of trust and reliability.Looking ahead, [PCB Assembly Firm] aims to continue its growth trajectory by staying at the forefront of technological advancements in the PCB assembly industry. The company plans to invest further in research and development to better serve its clients' evolving needs and to expand its geographic reach.About [PCB Assembly Firm]:[PCB Assembly Firm] is a leading PCB assembly firm based in [City, State]. The company provides comprehensive PCB assembly services, utilizing cutting-edge technology, world-class equipment, and a skilled workforce to meet the diverse needs of its clientele. With a commitment to quality, efficiency, and customer satisfaction, [PCB Assembly Firm] has built a reputation as a trusted and reliable PCB assembly partner.Media Contact:[Person Name][Title][Company Name][Email Address][Phone Number]

Expert Guide to Pcb Assembly At Home: Everything You Need to Know

In recent years, there has been a growing trend in the electronics industry towards home-based PCB assembly. With the advancement of technology and the availability of DIY kits, individuals are now able to assemble their own PCBs from the comfort of their homes. This trend has been further fueled by the increasing demand for custom electronic projects and prototypes, as well as the desire for more control and flexibility in the assembly process.One company at the forefront of this movement is {}. With a long history of providing high-quality PCB assembly services to a wide range of industries, they have now expanded their offerings to include a line of products specifically designed for home-based assembly. These products include DIY assembly kits, step-by-step instructions, and all the necessary components to help individuals create their own electronic devices at home.The shift towards home-based PCB assembly has opened up a world of possibilities for electronics enthusiasts, hobbyists, and small businesses. It allows them to take their ideas from concept to reality without the need for expensive equipment or specialized knowledge. This democratization of the assembly process has empowered individuals to explore their creativity and bring their innovative ideas to life.Additionally, home-based assembly offers numerous benefits such as cost savings, convenience, and the ability to work at one's own pace. This can be particularly advantageous for small businesses and startups looking to reduce their overhead costs and speed up the prototyping process. It also provides individuals with a greater sense of ownership and satisfaction, knowing that they have personally assembled their electronic devices from start to finish.Furthermore, home-based assembly is environmentally friendly as it reduces the need for mass production and the associated waste. By allowing individuals to only produce the quantity they need, it helps to minimize excess inventory and resources. This aligns with the growing consumer demand for sustainable and eco-friendly products, making home-based PCB assembly a win-win for both individuals and the environment.{Company} is committed to supporting this growing trend by providing comprehensive resources and support for home-based PCB assembly. They have developed a user-friendly platform that guides individuals through the entire assembly process, from choosing the right components to soldering and testing the final product. Additionally, their team of experts is readily available to offer guidance and technical support to ensure a smooth and successful assembly experience.In conclusion, the rise of home-based PCB assembly represents a significant shift in the electronics industry. It has empowered individuals to take control of the assembly process, fostering creativity, cost savings, and environmental sustainability. With the support of companies like {}, home-based assembly is expected to continue growing and shaping the future of electronics manufacturing.

A Comprehensive Guide to Au Wire Bonding in China: Everything You Need to Know

China's Advanced Ultrasonic Wire Bonding Technology Poised to Revolutionize the Electronics IndustryIn a rapidly evolving world of technology, China has once again showcased its prowess by introducing a groundbreaking innovation in the field of wire bonding. Developed by a prominent technological company, this new technology promises to revolutionize the electronics industry by enhancing the efficiency and reliability of wire bonding processes.Wire bonding plays a crucial role in the assembly of electronic components, serving as the backbone that connects semiconductors to various interconnects. The conventional wire bonding techniques have long been employed in the industry, but limitations in terms of speed and precision demanded a more advanced solution. This is where China Au Wire Bonding steps in, providing a cutting-edge approach to wire bonding that addresses these shortcomings.China Au Wire Bonding leverages advanced ultrasonic bonding technology, which utilizes high-frequency vibrations to create strong interconnections between wires and bonding surfaces. Unlike traditional methods, this innovative technique ensures a significant reduction in bonding time without compromising on quality. Through precise control and monitoring of ultrasonic waves, the bonding process is not only expedited but also guarantees superior reliability.With its technical superiority, China Au Wire Bonding is capable of bonding different types of wires, including gold wires, aluminum wires, and copper wires, all with exceptional accuracy. This versatility enables manufacturers to explore various options without being restricted by specific material requirements, thus pushing the boundaries of what is possible in the electronics industry.Furthermore, this disruptive technology addresses one of the industry's most persistent challenges – wire sag. Wire sag occurs when wires lose tension during the bonding process, resulting in compromised connection quality. China Au Wire Bonding boasts a unique adaptive bonding system that eliminates wire sag by continuously adjusting tension, ensuring consistent and reliable wire bonds.Beyond its technical capabilities, China Au Wire Bonding also presents a cost-effective solution for manufacturers. By significantly reducing bonding time, manufacturers can streamline their production processes, maximize output, and minimize operational costs. Additionally, the exceptional reliability of the wire bonds minimizes the need for post-assembly inspections, saving both time and resources.Chinese companies, such as {} (company name), have already embraced this innovative technology, which serves as a testament to its quality and effectiveness. With an uncompromising focus on research and development, {} has emerged as a pioneer in the field, leading the way for other players in the industry. Through continuous innovation and collaboration, China Au Wire Bonding is poised to become the gold standard for wire bonding technologies worldwide.The introduction of China Au Wire Bonding is a game-changer for the electronics industry, elevating wire bonding to new heights. Its advanced ultrasonic bonding technology brings unmatched speed, precision, and reliability, enabling manufacturers to stay at the forefront of technological advancements. With its cost-effectiveness and versatility, this technology is set to reshape the industry's landscape, opening up endless possibilities for the development of cutting-edge electronic devices.As China continues to solidify its position as a global technological powerhouse, advancements like China Au Wire Bonding highlight the nation's commitment to innovation and its relentless pursuit of excellence. With its immense potential, this groundbreaking technology is set to transform the electronics industry, accelerating the pace of technological advancement and propelling China to the forefront of global technological leadership.

Exploring the Latest Trends in Through Hole Manufacturing: An In-depth Analysis Reveals Impressive Growth Potential

Title: SMT Through Hole Manufacturers Revolutionizing PCB Manufacturing ProcessIntroduction:In today's fast-paced world, the electronic industry is evolving rapidly with the increasing demands for innovative solutions across various sectors. One crucial component that lays the foundation for electronic devices is the printed circuit board (PCB). As manufacturers strive to enhance the efficiency and reliability of PCBs, SMT (Surface Mount Technology) through-hole manufacturing companies are playing a pivotal role in transforming the manufacturing process. This article explores the significance of SMT through-hole manufacturers {} in revolutionizing the field of PCB manufacturing.I. Understanding SMT Through Hole Technology:SMT through-hole technology represents a groundbreaking manufacturing technique in the electronic industry. It involves the utilization of components mounted directly onto the surface of a PCB, eliminating the need for traditional through-hole connections. This innovative method offers several advantages, including improved efficiency, reduced costs, and enhanced electrical performance.II. The Role of SMT Through Hole Manufacturers:SMT through-hole manufacturers play a crucial role in the PCB manufacturing process. They specialize in producing high-quality, reliable, and cost-effective PCBs that meet the specific needs of various industries. Through advanced technologies, these manufacturers optimize the production process, leading to enhanced product performance and shortened delivery times.III. Advanced Manufacturing Techniques:SMT through-hole manufacturers capitalize on cutting-edge manufacturing techniques to ensure the highest standards of quality and precision. They employ state-of-the-art machinery and equipment, including automated assembly lines, precision soldering robots, and computer-controlled inspection systems. These technologies allow for high-volume production with exceptional consistency and accuracy, reducing the risk of errors and defects.IV. Quality Control and Certification:Recognizing the critical importance of quality control in PCB manufacturing, SMT through-hole manufacturers adhere to rigorous quality standards. They implement comprehensive testing procedures, such as automated optical inspection (AOI) and X-ray inspection, to identify and rectify any manufacturing issues. Additionally, these manufacturers often hold certifications such as ISO 9001, ISO 14001, and ISO/TS 16949, signifying their commitment to maintaining the highest quality benchmarks.V. Customization and Flexibility:SMT through-hole manufacturers understand that different industries require unique PCB designs to meet their specific requirements. With their technological expertise and experience, these manufacturers offer customized solutions tailored to the needs of individual clients. Whether it's designing specialized PCBs for automotive applications, aerospace systems, or consumer electronics, they can adapt to diverse specifications and deliver highly optimized solutions.VI. Environmental Sustainability:In today's environmentally conscious world, SMT through-hole manufacturers believe in sustainable manufacturing practices. They prioritize the use of eco-friendly materials and state-of-the-art waste management systems. By reducing waste, minimizing energy consumption, and adhering to strict environmental regulations, these manufacturers contribute to a greener future.VII. Future Perspectives and Innovation:SMT through-hole manufacturers continuously invest in research and development to stay at the forefront of technological advancements in the electronic industry. With the emergence of IoT devices, autonomous vehicles, and smart cities, these manufacturers are constantly adapting to the evolving needs of the market. They are exploring the potential of emerging technologies, such as 5G connectivity, artificial intelligence, and machine learning, to ensure their PCBs are equipped for the digital future.Conclusion:The contribution of SMT through-hole manufacturers in revolutionizing the PCB manufacturing process cannot be underestimated. Their focus on advanced manufacturing techniques, stringent quality control, customization, environmental sustainability, and innovation propels the electronic industry forward. As the demand for efficient and reliable electronic devices continues to grow, SMT through-hole manufacturers will undoubtedly play an integral role in shaping the future of PCB manufacturing.

Top Security 6410 Module Supplier Reveals Latest Trends in the Industry

Security 6410 Module Supplier Introduces Advanced Security Solutions[City, State] - In a move to revolutionize the security industry, a leading module supplier, renowned for its cutting-edge technology, proudly announces the launch of its latest product, the Security 6410 Module. This groundbreaking solution is set to redefine security standards, offering advanced features that ensure unparalleled protection against potential threats.With decades of experience in providing top-of-the-line security solutions, [Company Name] is a trusted name in the industry. The company's commitment to innovation and excellence has constantly pushed the boundaries of what is possible in the security field. With the Security 6410 Module, [Company Name] aims to further strengthen its presence and solidify its position as a market leader.The Security 6410 Module benefits from the combination of state-of-the-art hardware and intelligent software, resulting in a seamless and robust security system. Equipped with advanced detection algorithms, this solution provides reliable and accurate threat identification, enabling prompt response and mitigation.One of the standout features of the Security 6410 Module is its ability to seamlessly integrate with existing security systems. This allows for an easy transition and upgrade for businesses and organizations that are looking to enhance their security measures. Additionally, the module supports a wide range of connectivity options, ensuring compatibility with various security devices and protocols.Another key aspect that sets the Security 6410 Module apart is its cutting-edge encryption technology. With cyberthreats becoming increasingly sophisticated, data security has become a paramount concern for businesses. Recognizing this, [Company Name] has incorporated robust encryption protocols into the module, safeguarding sensitive information from unauthorized access.Alongside its numerous security features, the Security 6410 Module is designed to be user-friendly and accessible to both technical and non-technical users. With a sleek interface and intuitive controls, the module can be easily operated and managed, minimizing complexity and maximizing effectiveness.In addition to its security benefits, the Security 6410 Module offers valuable insights through its comprehensive data analytics capabilities. By leveraging machine learning algorithms, the module can detect patterns and trends within security data, empowering businesses to make informed decisions and take proactive measures to mitigate future risks.As demand for advanced security solutions continues to rise, [Company Name] is dedicated to ensuring the widespread availability of the Security 6410 Module. The company has established partnerships and distribution channels both locally and internationally, making the module accessible to businesses and organizations across the globe.Commenting on the launch, [Mr./Ms. Name], [Position] at [Company Name], expressed excitement about the Security 6410 Module and its potential impact on the industry. "We are thrilled to introduce the Security 6410 Module to the market. With its powerful features and advanced technology, we believe it will greatly enhance security operations and provide our customers with a comprehensive solution to combat emerging threats."[City, State] businesses and organizations can now take advantage of the Security 6410 Module to bolster their security infrastructure, safeguarding their assets, and ensuring the safety of their personnel.About [Company Name]:[Company Name] is a renowned module supplier specializing in advanced security solutions. With a focus on innovation and excellence, the company has consistently delivered cutting-edge products that redefine industry standards. By combining state-of-the-art hardware with intelligent software, [Company Name] continues to develop solutions that offer unmatched security and protection. With an extensive network of partners and distributors, [Company Name] serves customers globally, helping them stay ahead in an ever-evolving security landscape.Contact:[Company Name][Address][Phone][Email][Website]

Exploring the Pros and Cons of Prototype PCB Board Factories

Title: Prototype PCB Board Factories Revolutionize Electronics Manufacturing IndustryIntroduction:In a rapidly evolving technology landscape, prototype PCB board factories have emerged as a crucial component of the electronics manufacturing sector. By facilitating the production of prototype printed circuit boards (PCBs), these factories are revolutionizing the industry by accelerating the product development cycle, reducing time-to-market, and bringing innovation within reach of entrepreneurs and small enterprises.The Role of Prototype PCB Board Factories:Prototype PCB board factories serve as a bridge between design and mass production. With state-of-the-art manufacturing capabilities and expertise, they transform innovative ideas into functional prototypes. Through an integrated approach that encompasses design optimization, material selection, and fast prototyping, these factories ensure the rapid realization of an idea into a physical, testable product. Simultaneously, they help identify potential design flaws, ensuring the final product is highly reliable and meets the desired specifications.The Manufacturing Process:Prototype PCB board factories employ cutting-edge technology, automated machinery, and precise quality control measures to streamline the manufacturing process. Surface-mount technology (SMT) allows for the mounting of electronic components directly onto the PCB, enhancing efficiency and minimizing manufacturing costs. Furthermore, the use of surface-mount technology enables the creation of smaller and more compact PCBs, ideal for modern electronic devices.Advanced software tools such as Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) enable seamless collaboration between design engineers and the factory. These tools ensure the accurate translation of design files into manufacturing instructions, guaranteeing a precise replication of the product envisioned by the designer.The Impact on Time-to-Market:Historically, developing a prototype PCB could be a lengthy and costly process, hindering innovation and delaying time-to-market. However, with the rise of prototype PCB board factories, this process has been significantly accelerated. From the initial design to manufacturing the first working PCB, the time required has been drastically reduced, allowing innovators to iterate and refine their designs rapidly. This shortened development cycle fosters innovation and enables companies to respond swiftly to market demands.Enabling Entrepreneurs and Small Enterprises:Prototype PCB board factories have leveled the playing field for entrepreneurs and small enterprises seeking to bring their innovative products to market. Traditionally, the cost associated with producing a prototype has been a significant barrier to entry for many aspiring innovators. However, the availability of affordable, high-quality prototype PCBs has empowered entrepreneurs, giving them the opportunity to transform their ideas into tangible products without having to make substantial upfront investments. This democratization of the manufacturing process has fueled the growth of start-ups and nurtured a vibrant ecosystem of innovators.Ensuring Quality and Reliability:Prototype PCB board factories prioritize the quality and reliability of the manufactured prototypes. These factories employ stringent quality control measures at every step of the manufacturing process. Automated optical inspection (AOI), X-ray inspection, and flying probe testing are just a few of the techniques employed to guarantee that the final product adheres to the highest industry standards. By conducting extensive testing and verification before the mass production phase, manufacturers can identify any potential issues, rectify them, and deliver reliable prototypes to their clients.Looking Towards the Future:The increasing demand for technologically advanced products, coupled with the emergence of disruptive technologies such as the Internet of Things (IoT), artificial intelligence (AI), and 5G, emphasizes the necessity for agile and efficient prototype PCB board factories. These factories are well-positioned to support the growth of industries spanning from healthcare to automotive and from smart cities to consumer electronics.In conclusion, prototype PCB board factories are playing a pivotal role in transforming the electronics manufacturing industry. By providing entrepreneurs and small enterprises with access to affordable and high-quality prototype PCBs, they are catalyzing innovation and streamlining the time-to-market. With their advanced manufacturing capabilities, seamless collaboration with designers, and commitment to quality, these factories are shaping the future of electronics manufacturing and propelling industries towards exponential growth.

Discover the Advantages of High-Quality Wire Bonding for Au

Title: Revolutionizing Wire Bonding Technology: Unleashing High-Quality Au Wire BondingIntroduction (111 words):As technology continues to advance at an unprecedented pace, the need for cutting-edge wire bonding solutions is more significant than ever before. Today, we present an innovative breakthrough in the field of wire bonding that promises high-quality results and exceptional performance. In collaboration with a leading industry player, we are pleased to introduce a groundbreaking wire bonding technique that maximizes productivity and achieves unparalleled precision. This revolutionary technology, referred to as High-Quality Au Wire Bonding, holds the potential to disrupt existing norms and redefine industry standards. Read on to explore the extraordinary capabilities of this game-changing technology and its potential implications in various sectors.Section 1: The Deterioration of Conventional Wire Bonding (175 words):Conventional wire bonding techniques have long been the standard in the industry, helping to establish reliable electrical connections between integrated circuits (ICs) and the substrate. However, in recent years, the limitations of these traditional methods have become increasingly evident. Challenges associated with wire stability, wire-bond interconnects, and overall performance have prompted the need for a transformative solution.Section 2: Introducing High-Quality Au Wire Bonding (183 words):Responding to the shortcomings of conventional wire bonding, the collaboration between our company and a key industry partner has paved the way for High-Quality Au Wire Bonding. By incorporating cutting-edge materials and advanced manufacturing processes, this new technique offers a host of advantages over its predecessors.The utilization of gold wire, renowned for its superior conductivity and stability, ensures optimal electrical performance of the wire-bond interconnects. Furthermore, the refined manufacturing process lends itself to better control over wire looping, resulting in excellent wire-bond reliability.Section 3: Unleashing Unrivaled Performance and Durability (180 words):High-Quality Au Wire Bonding offers a range of impressive benefits, including enhanced electrical conductivity, superior mechanical strength, and improved long-term reliability. The utilization of gold wire eliminates concerns related to oxidation and corrosion, which are often encountered with alternative wire bonding materials. This ensures stable performance and durability, even under challenging environmental conditions.The precise control and consistency achieved during the manufacturing process also enable a reduction in defects and yield losses. Consequently, this groundbreaking technology provides manufacturers with significant cost savings and increased productivity.Section 4: Applications in Various Sectors (150 words):The adaptability and exceptional performance of High-Quality Au Wire Bonding provide immense opportunities for various sectors. Industries such as automotive, telecommunications, aerospace, and consumer electronics can benefit greatly from this cutting-edge wire bonding solution.New developments in electric vehicles (EVs) and autonomous driving technologies require highly reliable electrical connections, making High-Quality Au Wire Bonding an ideal choice. In the telecommunications sector, the need for high-speed data transfer necessitates robust wire bonding techniques, and this new technology excels in meeting these demands.Conclusion (101 words):High-Quality Au Wire Bonding represents a significant leap forward in the realm of wire bonding technology. Its unique advantages, including excellent electrical conductivity, enhanced mechanical strength, and increased durability, make it an invaluable tool for many industries. As we look towards the future, the potential implications and endless possibilities of this game-changing wire bonding technique are undeniably exciting. By embracing this revolutionary technology, manufacturers can achieve unparalleled precision, reliability, and productivity, ushering in a new era of wire bonding excellence.

Revolutionizing Manufacturing: The Benefits of High Volume Production

[Headline]: Major Company Achieves High Volume Production, Demonstrating Commitment to Industry Growth[Sub-heading]: Introduction of the Company and its Contributions to the Industry[Date]: [Insert Date][CITY], [STATE] - [Company Name], a leading player in the [industry/sector], has recently achieved remarkable success with its high-volume production process. The company's commitment to continuous improvement, technological advancements, and the pursuit of excellence has solidified its position as a trailblazer in the industry. With a focus on innovation and unmatched production capabilities, [Company Name] has become a benchmark for efficiency and reliability.[Company Name] has a rich history of serving the [industry/sector] for over [number] years. Founded in [year], the company has grown exponentially through its dedication to superior quality, customer satisfaction, and sustainable practices. From modest beginnings, [Company Name] has transformed into a global powerhouse, boasting an extensive network of production facilities and customers worldwide.Central to [Company Name]'s success is its commitment to high-volume production. This process enables the company to meet ever-increasing demand while maintaining consistent quality and competitive pricing. By leveraging advanced technologies, automation, and streamlined workflows, [Company Name] has revolutionized the industry's approach to large-scale manufacturing.To support its high-volume production capabilities, [Company Name] has made substantial investments in cutting-edge machinery, state-of-the-art equipment, and research and development initiatives. The company's commitment to innovation places it at the forefront of the industry, consistently introducing groundbreaking solutions that enhance productivity, reduce waste, and improve overall efficiency.The benefits of high-volume production are not limited to [Company Name] alone; the industry as a whole stands to gain from this achievement. By setting new benchmarks for efficiency and productivity, [Company Name] paves the way for increased competitiveness, supply chain optimization, and overall sector growth. Moreover, the company's commitment to sustainable practices ensures that high-volume production is achieved without compromising environmental responsibility.[Company Name]'s dedication to sustainable production is evident in its adoption of renewable energy sources, waste reduction strategies, and responsible sourcing. By aligning profitability with environmental stewardship, the company sets an example for others in the industry and serves as a catalyst for positive change. High-volume production, when executed responsibly, can drive economic growth while minimizing the ecological footprint associated with manufacturing processes.The success of [Company Name]'s high-volume production process has garnered praise from industry experts and customers alike. The ability to consistently deliver large quantities of products while maintaining quality and adhering to tight timelines is a testament to the company's prowess. In an ever-evolving market, where customer demands are on the rise, [Company Name] stands as a reliable partner that can meet and exceed expectations.Looking ahead, [Company Name] intends to further enhance its high-volume production capabilities by embracing emerging technologies such as artificial intelligence, data analytics, and predictive modeling. These investments will facilitate even greater efficiency, reliability, and scalability, cementing the company's position as an industry leader.In conclusion, [Company Name]'s recent achievement in high-volume production underscores its unwavering commitment to industry growth, innovation, and sustainability. By combining advanced technologies, state-of-the-art production facilities, and a dedicated workforce, the company sets new industry standards and showcases the immense potential of large-scale manufacturing. As [Company Name] continues to push boundaries, the industry will undoubtedly benefit, fostering progress and prosperity for all involved.

Gold Ribbon Bonding Supplier: Meeting Demands for Quality Bonding Services

[Company Introduction][Company Name] is a leading provider of innovative bonding solutions in the electronics industry. With a focus on research and development, our company is committed to supplying high-quality gold ribbon bonding products to manufacturers worldwide. As a trusted partner, we strive to meet the ever-evolving demands of our customers, enabling them to enhance the performance and reliability of their electronic devices.Our state-of-the-art manufacturing facilities, coupled with an experienced team of engineers and technicians, position us at the forefront of the industry. We take pride in our ability to deliver customized solutions tailored to our customers' specific requirements. Whether it is bonding wires for semiconductors, LED packages, or any other electronic component, our gold ribbon bonding products are designed to provide exceptional conductivity and stability, ensuring the longevity of electronic devices in diverse applications.With a strong emphasis on technological innovation, we constantly invest in research and development activities. Our dedicated team of engineers collaborates with industry experts and academic institutions to explore novel bonding techniques and materials. This commitment to innovation drives us to continuously improve our products and offer advanced bonding solutions that empower our customers to excel in a highly competitive market.In addition to our dedication to quality and innovation, we place great importance on sustainability and environmental responsibility. Our manufacturing processes adhere to stringent environmental regulations and best practices, striving to minimize the impact on the planet while maintaining the highest standards of product performance. We are committed to promoting sustainability across the industry and actively seek partnerships with like-minded organizations to drive positive change.[News][Date], [Company Name] announced its latest breakthrough in the field of gold ribbon bonding, revolutionizing the electronics industry with its advanced bonding products and techniques. The company's continued commitment to technological innovation has positioned it as a leading supplier of gold ribbon bonding solutions, catering to the diverse needs of manufacturers worldwide.The new range of gold ribbon bonding products introduced by [Company Name] offers improved conductivity, reliability, and ease of use. With enhanced performance characteristics, manufacturers can now improve the efficiency and functionality of their electronic devices, meeting the ever-increasing demands of consumers in today's digital age.One of the key highlights of the new product line is its compatibility with a wide range of electronic components. Whether it is bonding wires for semiconductors, LED packages, or other critical components, [Company Name]'s gold ribbon bonding products ensure seamless integration, providing manufacturers with a versatile solution suitable for various applications.The advanced bonding techniques developed by [Company Name] have also been met with great enthusiasm within the industry. By leveraging state-of-the-art manufacturing processes and materials, the company has significantly increased the bond strength and durability of its gold ribbon bonding products. This breakthrough not only enhances the lifespan of electronic devices but also improves their resistance to environmental factors such as temperature fluctuations and mechanical stress.Furthermore, [Company Name]'s commitment to sustainability has resulted in the development of eco-friendly gold ribbon bonding solutions. These products adhere to the highest environmental standards, without compromising on performance or reliability. As electronic waste continues to be a growing concern, [Company Name] aims to provide manufacturers with innovative bonding solutions that minimize environmental impact and promote a more sustainable electronics industry.As a leading bonding supplier, [Company Name]'s dedication to customer satisfaction remains unparalleled. The company's global network of experts ensures comprehensive technical support and reliable customer service, aiding manufacturers in every step of their bonding processes. By fostering long-term partnerships with clients, [Company Name] continually adapts its solutions to align with the evolving needs of the electronics industry.With its latest advancements in gold ribbon bonding, [Company Name] sets a new benchmark for excellence in the electronics industry. By combining innovation, sustainability, and customer-centricity, the company reaffirms its position as a trusted partner for manufacturers seeking cutting-edge bonding solutions. As the industry continues to evolve, [Company Name] remains committed to pushing the boundaries of gold ribbon bonding technology, empowering manufacturers to deliver high-performance electronic devices that shape the world we live in.