Reliable PCB Assembly Services for Your Electronics Manufacturing Needs

By:Admin

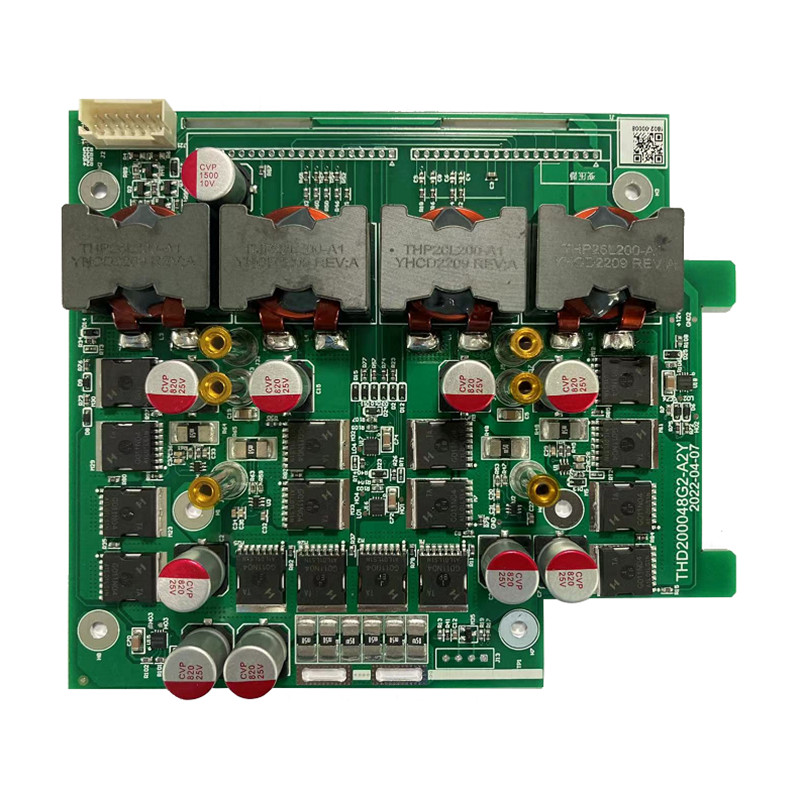

The company specializes in providing complete turnkey PCB assembly services, including PCB fabrication, component procurement, PCB assembly, testing, and packaging. With state-of-the-art facilities and a team of experienced engineers and technicians, One Stop Pcb Assembly has the capabilities to handle projects of any size and complexity.

One Stop Pcb Assembly is dedicated to meeting the unique requirements of each customer, offering flexible and customizable solutions to ensure that every project is completed to the highest standards. Whether it's a prototype, low-volume production, or high-volume production run, the company has the expertise and resources to deliver exceptional results.

One of the key advantages of partnering with One Stop Pcb Assembly is the company's commitment to quality and reliability. By leveraging the latest technologies and adhering to stringent quality control processes, the company ensures that every PCB assembly meets the highest industry standards. Additionally, One Stop Pcb Assembly is ISO 9001 certified, further demonstrating its dedication to delivering excellence in every aspect of its operations.

Furthermore, the company's dedication to customer satisfaction is evident in its responsive and proactive approach. From the initial consultation to the final delivery, the team at One Stop Pcb Assembly works closely with customers to understand their unique needs and provide tailored solutions that meet or exceed expectations. This customer-centric approach has earned the company a strong reputation for reliability, professionalism, and integrity.

In addition to its commitment to quality and customer satisfaction, One Stop Pcb Assembly is also focused on staying at the forefront of technological advancements in the PCB assembly industry. The company continually invests in research and development, as well as staff training, to ensure that it remains at the cutting edge of innovation and can effectively meet the evolving needs of its customers.

One Stop Pcb Assembly serves a diverse range of industries, including telecommunications, consumer electronics, automotive, aerospace, medical devices, and more. The company's ability to adapt to the unique requirements of each industry and provide specialized solutions has made it a preferred partner for businesses around the world.

To further support its global customer base, One Stop Pcb Assembly offers flexible shipping options and excellent post-sales support, ensuring that customers receive their PCB assemblies on time and are fully satisfied with the final product.

In conclusion, One Stop Pcb Assembly is dedicated to providing comprehensive, high-quality PCB assembly solutions that meet the unique needs of its customers. With a focus on quality, reliability, innovation, and customer satisfaction, the company continues to be a leading player in the PCB assembly industry. Whether it's a small prototype project or a large-scale production run, businesses can trust One Stop Pcb Assembly to deliver exceptional results.

Company News & Blog

Top Welding Factories to Meet Your Industrial Needs

Welding Factories in need of a reliable and efficient welding solution can now turn to the innovative products and services offered by {}.{} is a leading provider of welding equipment and solutions for a wide range of industries and applications. With a strong commitment to quality, innovation, and customer satisfaction, the company has established a solid reputation as a trusted partner for welding factories around the world.One of the primary reasons why welding factories choose {} as their preferred welding solution provider is the company's extensive range of high-quality products. From welding machines and equipment to consumables, accessories, and safety gear, {} offers a comprehensive selection of products that are designed to meet the diverse needs of welding factories.In addition to its impressive product range, {} also prides itself on its ability to provide customized solutions for welding factories. The company's team of experienced engineers and technical specialists works closely with each client to understand their specific requirements and develop tailored solutions that meet their needs. This personalized approach sets {} apart from other welding equipment providers and ensures that clients receive the best possible solution for their welding applications.Moreover, {} is committed to staying at the forefront of welding technology and innovation. The company invests heavily in research and development to continuously improve its products and develop new, cutting-edge solutions for the welding industry. By staying ahead of the curve, {} ensures that its clients have access to the latest and most advanced welding technologies, helping them improve efficiency, productivity, and quality in their welding operations.In addition to its product offerings, {} is also known for its exceptional customer service and support. The company's team of dedicated professionals is always available to provide assistance, guidance, and technical support to welding factories. Whether it's helping clients select the right equipment, addressing technical issues, or providing training and education, {} is committed to being a reliable and responsive partner for its clients.Furthermore, {} is deeply committed to sustainability and environmental responsibility. The company recognizes the importance of minimizing its environmental impact and promoting sustainable practices within the welding industry. As such, {} has implemented various initiatives to reduce energy consumption, waste generation, and emissions, while also developing eco-friendly products and solutions for its clients.With its comprehensive product range, custom solutions, commitment to innovation, exceptional customer service, and sustainable practices, {} has firmly established itself as a global leader in the welding industry. Welding factories looking for a reliable and efficient welding solution can trust {} to meet their needs and help them achieve their welding objectives.To learn more about {} and its products and services, visit the company's website or contact their team directly for personalized assistance. With its unwavering dedication to quality, innovation, and customer satisfaction, {} is the ideal partner for welding factories seeking a trusted and reliable welding solution provider.

Master the Art of Surface Mounting Soldering Techniques for Exceptional Results

Surface Mounting Soldering Revolutionizes Electronic ManufacturingIn today's rapidly evolving world, technology plays an integral role in our daily lives. From smartphones to smart homes, the demand for advanced electronic devices continues to soar. Behind the scenes, electronic manufacturers strive to keep up with consumer expectations by constantly upgrading their manufacturing processes. One such breakthrough is surface mounting soldering, a technique that has revolutionized the industry by offering speed, precision, and efficiency.Surface mounting soldering, or SMT, is a method used to assemble electronic circuits where the components are directly mounted onto the surface of a printed circuit board (PCB). Unlike traditional through-hole soldering, which involves inserting leads through holes on the PCB, SMT eliminates the need for holes and allows for smaller, more compact devices. This technique has become increasingly popular due to its ability to meet the growing demand for smaller, smarter, and more portable electronic products.With the rise of SMT, manufacturers can now design and produce devices that are not only aesthetically appealing but also highly-functional. By eliminating the bulky components and minimizing the space required, SMT allows for the creation of sleek and lightweight products that fit seamlessly into our increasingly connected world. From wearables to Internet of Things (IoT) devices, the applications of SMT are virtually limitless.One of the key benefits of surface mounting soldering is its ability to improve the speed and efficiency of the manufacturing process. Traditional through-hole soldering involves manually soldering each component onto the PCB, a time-consuming and labor-intensive task. In contrast, SMT utilizes automated pick-and-place machines that can accurately place multiple components simultaneously, reducing the assembly time significantly. This results in faster production cycles, allowing manufacturers to meet consumer demands more efficiently and cost-effectively.Furthermore, SMT offers superior precision and reliability compared to through-hole soldering. The automated machines used in SMT ensure consistent component placement, guaranteeing a higher level of accuracy. The solder joints formed in SMT also tend to be smaller and more reliable, as the surface tension distributes the molten solder evenly and creates stronger connections. This ensures the long-term reliability of the electronic devices and reduces the risk of failures or malfunctions.In addition to its speed and precision, surface mounting soldering also promotes sustainability in electronic manufacturing. SMT allows manufacturers to minimize the amount of waste generated during the assembly process. With through-hole soldering, excess leads and wires are often cut off and discarded, leading to unnecessary material wastage. However, SMT's minimalistic design approach reduces the amount of material required and maximizes the utilization of resources, making it a greener option for the industry.{Company intro}: As a leading innovator in the electronics manufacturing industry, our company is at the forefront of adopting SMT technology. We understand the increasing demands of consumers for smaller, faster, and smarter devices, and aim to meet those demands through the integration of surface mounting soldering into our manufacturing processes. Our state-of-the-art facilities house the latest pick-and-place machines and cutting-edge SMT equipment, enabling us to deliver high-quality products with exceptional precision and reliability.With the advent of surface mounting soldering, the landscape of electronic manufacturing has been forever transformed. This advanced technique has not only improved the quality, performance, and aesthetics of electronic devices but has also enhanced the overall manufacturing process. By embracing the benefits of SMT, manufacturers can meet consumer demands more efficiently, reduce waste, and contribute to a more sustainable future in the industry. As technology continues to evolve, surface mounting soldering will undoubtedly remain a vital tool for innovators pushing the boundaries of what is possible in the electronic realm.

High-quality PCB assembly factories for EMS services

Ems Pcb Assembly Factories (need remove brand name) is a leading electronic manufacturing services company that specializes in providing high-quality PCB assembly, design, and testing services to a wide range of industries. With state-of-the-art facilities and a highly skilled team of engineers and technicians, the company is committed to delivering innovative and cost-effective solutions for its customers.The company's PCB assembly services encompass a wide range of capabilities, including surface mount technology (SMT), through-hole assembly, and mixed technology assembly. This allows them to accommodate the unique requirements of each project and provide customized solutions that meet their customers' exact specifications.In addition to their assembly capabilities, they also offer comprehensive design services to help customers bring their electronic products from concept to reality. Their team of experienced designers and engineers work closely with customers to develop efficient and reliable PCB designs that optimize performance and maximize cost-efficiency.Furthermore, the company's testing and inspection capabilities ensure that every product meets the highest quality standards before it leaves the facility. Their rigorous testing procedures and quality control measures guarantee that each PCB assembly meets the strictest specifications and performance requirements.One of the key differentiators for the company is its commitment to sustainability and environmental responsibility. They prioritize eco-friendly manufacturing processes and materials to minimize their environmental impact while delivering exceptional products to their customers. This commitment to sustainability has earned them a reputation as a responsible and forward-thinking electronic manufacturing services provider.With a focus on continuous improvement and innovation, (company name) is constantly investing in the latest technologies and manufacturing equipment to stay at the forefront of the industry. This dedication to staying ahead of market trends and technological advancements enables them to deliver cutting-edge solutions that meet the evolving needs of their customers.In a recent interview with the company's CEO, he emphasized their dedication to customer satisfaction and their ability to support projects at any stage of development. "We take pride in our ability to provide flexible and scalable solutions that adapt to our customers' unique challenges," he said. "Whether they are in the early stages of product development or require full-scale production, our team is equipped to deliver the highest quality PCB assemblies on time and within budget."The company's commitment to excellence and customer-centric approach has earned them a strong reputation in the electronic manufacturing services industry. They have built long-standing relationships with a diverse clientele, ranging from startups to Fortune 500 companies, and are the preferred partner for numerous industries, including aerospace, medical, telecommunications, and automotive.Looking towards the future, (company name) continues to expand its capabilities and invest in its people and technology to better serve their customers and maintain their position as a leader in the electronic manufacturing services industry. By staying true to their core values of quality, innovation, and customer satisfaction, they are confident in their continued success and growth in the years to come.In conclusion, (company name) is a trusted and reliable partner for companies seeking high-quality PCB assembly, design, and testing services. With a commitment to excellence, innovation, and sustainability, they have established themselves as a leader in the electronic manufacturing services industry and continue to provide exceptional solutions for a wide range of industries.

China Assembled PCBs: Expertly Crafted Components for Optimal Performance

China Components Assembled PCB: Revolutionizing the Electronics IndustryIntroduction:In today's rapidly evolving world, the electronics industry is facing constant pressure to manufacture smaller, faster, and more advanced devices. A critical component of this industry is the Printed Circuit Board (PCB), which acts as the backbone for electronic circuits. With the rise of smart devices, IoT, and autonomous technologies, the demand for electronic components and PCBs has never been greater.China, with its vast manufacturing capabilities and technological advancements, has become a dominant player in the global PCB market. Chinese companies are leveraging their expertise in PCB assembly to provide cutting-edge solutions that address the evolving needs of industries.China Components Assembled PCB (Company Name), founded in (year), is at the forefront of this revolution. With their commitment to innovation, product quality, and customer service, they have emerged as a leading player in the Chinese PCB assembly market.Market Position:China Components Assembled PCB has positioned itself as a reliable and cost-effective PCB assembly solution provider. By leveraging advanced technologies and automated manufacturing processes, the company delivers high-quality PCBs at competitive prices. Their commitment to customer satisfaction has earned them a strong reputation among both domestic and international clients.Manufacturing Capability:China Components Assembled PCB operates state-of-the-art manufacturing facilities equipped with industry-leading machinery and automated production lines. These facilities enable them to meet the increasing demand for complex and technologically advanced PCBs. The company's manufacturing processes adhere to stringent quality standards, ensuring defect-free products.Product Range:The company offers a wide range of PCB assembly services for various industries, including consumer electronics, automotive, aerospace, telecommunications, and medical devices. They are capable of manufacturing single-sided, double-sided, and multi-layered PCBs with varying complexities.China Components Assembled PCB's engineering team works closely with customers to understand their specific requirements and design custom PCB solutions. They provide support throughout the entire production process, from initial design to the final assembly, ensuring a seamless experience for their clients.Quality Assurance:Quality is a top priority for China Components Assembled PCB. They employ rigorous quality control measures at every stage of production, including raw material inspection, assembly, and testing. The company is ISO certified, further underscoring their commitment to delivering superior products.Their testing procedures include automated optical inspection (AOI), X-ray inspection, functional testing, and reliability testing. These measures guarantee that every PCB leaving their facility meets the highest quality standards.Global Reach:China Components Assembled PCB has a strong global presence, catering to clients from around the world. Their ability to deliver high-quality products within tight deadlines has positioned them as a trusted partner for many international businesses.Market Outlook:The demand for PCBs is expected to grow significantly in the coming years. With the rise of emerging technologies such as 5G, artificial intelligence, and electric vehicles, the electronics industry is poised for unprecedented growth. China Components Assembled PCB is well-equipped to capitalize on this market boom by consistently delivering innovative and reliable PCB assembly solutions.Conclusion:China Components Assembled PCB's commitment to quality, cutting-edge technology, and customer satisfaction has propelled them to the forefront of the Chinese PCB assembly industry. Their ability to manufacture complex and advanced PCBs at competitive prices has attracted a wide range of clients from various sectors. As the electronics industry continues to evolve, China Components Assembled PCB's dedication to innovation positions them for further success in the global market.

What Is Chip On Board Technology and How Does It Impact Electronics?

Chip On Board (COB) technology has been making waves in the electronics industry, and now, a leading company in the field is ready to revolutionize the market with their latest COB products. With their innovative approach to manufacturing and dedication to quality, the company is set to become a key player in the COB market.Established in [year], the company has been at the forefront of electronic component manufacturing for over a decade. Their commitment to research and development has led to several breakthroughs in COB technology, positioning them as a go-to source for high-quality COB products. With a state-of-the-art manufacturing facility and a team of skilled engineers and technicians, the company has the capability to produce COB products that meet the highest industry standards.COB technology has emerged as a game-changer in the electronics industry, offering a compact and efficient solution for various applications. By directly mounting the LED chip on a substrate, COB technology eliminates the need for traditional LED packaging, resulting in a more compact and lightweight design. This technology also enables higher light output and improved thermal management, making COB products a popular choice for lighting, automotive, and display applications.The company's latest line of COB products is set to raise the bar for COB technology. With a focus on performance, reliability, and versatility, these products are designed to meet the demanding requirements of various applications. Whether it's for indoor or outdoor lighting, automotive headlights, or electronic displays, the company's COB products are engineered to deliver superior performance and efficiency.One of the key advantages of the company's COB products is their advanced thermal management system. By efficiently dissipating heat from the LED chip, these products are able to maintain optimal performance and extend their lifespan. This makes them a cost-effective solution for customers, as they require minimal maintenance and replacement.In addition to their robust performance, the company's COB products also boast a compact and lightweight design, making them easy to integrate into various applications. With their high-density integration and uniform light distribution, these products offer a versatile solution for designers and engineers looking to optimize the performance of their products.Furthermore, the company's commitment to quality and reliability is evident in their rigorous testing and quality control processes. Every COB product undergoes comprehensive testing to ensure that it meets the company's strict standards for performance and durability. This dedication to quality has earned the company a reputation for delivering COB products that customers can rely on.As the demand for COB technology continues to grow across various industries, the company is poised to capitalize on this trend with their exceptional COB products. With a focus on innovation, quality, and customer satisfaction, the company is well-positioned to emerge as a leader in the COB market.In conclusion, the company's latest line of COB products represents a significant leap forward in COB technology. With their advanced thermal management, compact design, and exceptional performance, these products are poised to set new standards in the industry. As the company continues to push the boundaries of COB technology, they are set to solidify their position as a key player in the rapidly evolving COB market.

Pcb Assembly Services for Surface Mount Technology

The demand for electronic devices continues to grow, with consumers seeking smaller, more powerful, and more efficient products. To meet this demand, {} has announced the launch of their new surface mount PCB assembly, providing customers with advanced technology and high-quality assembly services.{} is a leading provider of electronic manufacturing services, offering a wide range of solutions for businesses in various industries. With a focus on innovation and customer satisfaction, {} has established itself as a trusted partner for companies seeking reliable and cost-effective electronic manufacturing solutions.The new surface mount PCB assembly is designed to meet the growing demand for compact and high-performance electronic devices. By utilizing state-of-the-art technology and advanced assembly techniques, {} is able to deliver PCBs that are smaller, lighter, and more efficient than traditional through-hole assembly methods.One of the key advantages of surface mount PCB assembly is its ability to accommodate increasingly complex designs. With the growing trend towards miniaturization, electronic devices are becoming smaller and more compact. Surface mount technology allows for the placement of components directly onto the surface of the PCB, making it possible to create smaller and more densely populated circuit boards without sacrificing performance.In addition to its size advantages, surface mount PCB assembly also offers improved performance and reliability. By eliminating the need for drilled holes and the use of leads, surface mount technology reduces the risk of mechanical failures and improves the overall electrical performance of the PCB. This makes it an ideal choice for applications that require high-speed and high-frequency operation.Furthermore, {}'s surface mount PCB assembly process is highly automated, allowing for increased efficiency and cost savings. By utilizing advanced pick-and-place machines and reflow soldering techniques, {} is able to achieve higher levels of precision and consistency in the assembly process. This results in higher-quality PCBs with fewer defects, ultimately saving time and money for their customers.With the launch of their new surface mount PCB assembly, {} is well-positioned to meet the evolving needs of the electronic manufacturing industry. By leveraging their expertise and state-of-the-art facilities, {} is able to provide customers with cutting-edge assembly solutions that are tailored to their specific requirements.As a leading provider of electronic manufacturing services, {} is committed to delivering exceptional value to their customers. Whether it's through their advanced assembly capabilities, innovative solutions, or dedicated customer support, {} strives to exceed expectations and establish long-lasting partnerships with their clients.In conclusion, the launch of {}'s new surface mount PCB assembly represents a significant milestone in the company's commitment to innovation and excellence. By offering advanced technology, high-quality assembly services, and exceptional value, {} is poised to continue serving as a trusted partner for businesses in need of reliable electronic manufacturing solutions.

Important Features to Consider in a Medical Device Motherboard

Medical Device Motherboard, in collaboration with industry leader in medical technology, {} has announced the launch of a breakthrough medical device motherboard that promises to revolutionize the healthcare industry. The new motherboard, which is the result of extensive research and development, is designed to provide unparalleled performance and reliability for a wide range of medical devices and equipment.The medical device motherboard is a critical component in medical devices such as patient monitoring systems, diagnostic equipment, and imaging devices. It serves as the central hub for processing and communicating data, and its performance and reliability are crucial for the accurate and timely delivery of healthcare services.The new medical device motherboard from {} and {}, offers several key improvements over existing solutions. It is built on the latest technology, utilizing state-of-the-art components and advanced manufacturing processes to ensure optimal performance and durability. This means that medical devices equipped with this motherboard will operate more efficiently and reliably, leading to better patient care and outcomes.The motherboard also incorporates advanced security features to protect sensitive patient data and ensure compliance with healthcare regulations. This is crucial in today’s increasingly connected healthcare environment, where cybersecurity threats pose a significant risk to patient safety and data privacy.Furthermore, the new medical device motherboard is designed to be highly customizable, allowing medical device manufacturers to tailor it to their specific requirements. This flexibility enables the development of innovative and specialized medical devices that can address the unique needs of healthcare providers and patients.In addition to its technical capabilities, the medical device motherboard also benefits from the extensive expertise and support of {}. As a leading provider of medical technology solutions, {} has a proven track record of delivering innovative and reliable products to the healthcare industry. Its deep understanding of the unique challenges and requirements of the healthcare sector makes it an ideal partner for the development and commercialization of the new medical device motherboard.The collaboration between {} and {} underscores the commitment of both companies to advancing healthcare technology and improving patient care. By combining their respective strengths and resources, they have been able to create a cutting-edge medical device motherboard that sets a new standard for performance, reliability, and security in medical devices.“We are thrilled to introduce this game-changing medical device motherboard in partnership with {}. This new technology represents a significant advancement in the field of medical devices, and we believe it will have a transformative impact on healthcare delivery,” said a spokesperson from {}.The launch of the new medical device motherboard comes at a time when the healthcare industry is undergoing rapid transformation, driven by technological advancements and evolving patient needs. With the increasing demand for connected and data-driven healthcare solutions, the availability of high-performance and secure medical device components is more important than ever.The new medical device motherboard from {} and {} is poised to address these evolving needs, offering a reliable and adaptable platform for the next generation of medical devices. Its availability is expected to catalyze the development of innovative healthcare solutions that can enhance patient care and support the efforts of healthcare providers.In conclusion, the launch of the new medical device motherboard from {} and {} represents a significant milestone in the advancement of medical technology. With its superior performance, reliability, and security features, this motherboard is set to positively impact the healthcare industry and contribute to improved patient outcomes. As healthcare technology continues to evolve, collaborations like this will play a crucial role in driving innovation and shaping the future of healthcare delivery.

Exploring the Pros and Cons of Prototype PCB Board Factories

Title: Prototype PCB Board Factories Revolutionize Electronics Manufacturing IndustryIntroduction:In a rapidly evolving technology landscape, prototype PCB board factories have emerged as a crucial component of the electronics manufacturing sector. By facilitating the production of prototype printed circuit boards (PCBs), these factories are revolutionizing the industry by accelerating the product development cycle, reducing time-to-market, and bringing innovation within reach of entrepreneurs and small enterprises.The Role of Prototype PCB Board Factories:Prototype PCB board factories serve as a bridge between design and mass production. With state-of-the-art manufacturing capabilities and expertise, they transform innovative ideas into functional prototypes. Through an integrated approach that encompasses design optimization, material selection, and fast prototyping, these factories ensure the rapid realization of an idea into a physical, testable product. Simultaneously, they help identify potential design flaws, ensuring the final product is highly reliable and meets the desired specifications.The Manufacturing Process:Prototype PCB board factories employ cutting-edge technology, automated machinery, and precise quality control measures to streamline the manufacturing process. Surface-mount technology (SMT) allows for the mounting of electronic components directly onto the PCB, enhancing efficiency and minimizing manufacturing costs. Furthermore, the use of surface-mount technology enables the creation of smaller and more compact PCBs, ideal for modern electronic devices.Advanced software tools such as Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) enable seamless collaboration between design engineers and the factory. These tools ensure the accurate translation of design files into manufacturing instructions, guaranteeing a precise replication of the product envisioned by the designer.The Impact on Time-to-Market:Historically, developing a prototype PCB could be a lengthy and costly process, hindering innovation and delaying time-to-market. However, with the rise of prototype PCB board factories, this process has been significantly accelerated. From the initial design to manufacturing the first working PCB, the time required has been drastically reduced, allowing innovators to iterate and refine their designs rapidly. This shortened development cycle fosters innovation and enables companies to respond swiftly to market demands.Enabling Entrepreneurs and Small Enterprises:Prototype PCB board factories have leveled the playing field for entrepreneurs and small enterprises seeking to bring their innovative products to market. Traditionally, the cost associated with producing a prototype has been a significant barrier to entry for many aspiring innovators. However, the availability of affordable, high-quality prototype PCBs has empowered entrepreneurs, giving them the opportunity to transform their ideas into tangible products without having to make substantial upfront investments. This democratization of the manufacturing process has fueled the growth of start-ups and nurtured a vibrant ecosystem of innovators.Ensuring Quality and Reliability:Prototype PCB board factories prioritize the quality and reliability of the manufactured prototypes. These factories employ stringent quality control measures at every step of the manufacturing process. Automated optical inspection (AOI), X-ray inspection, and flying probe testing are just a few of the techniques employed to guarantee that the final product adheres to the highest industry standards. By conducting extensive testing and verification before the mass production phase, manufacturers can identify any potential issues, rectify them, and deliver reliable prototypes to their clients.Looking Towards the Future:The increasing demand for technologically advanced products, coupled with the emergence of disruptive technologies such as the Internet of Things (IoT), artificial intelligence (AI), and 5G, emphasizes the necessity for agile and efficient prototype PCB board factories. These factories are well-positioned to support the growth of industries spanning from healthcare to automotive and from smart cities to consumer electronics.In conclusion, prototype PCB board factories are playing a pivotal role in transforming the electronics manufacturing industry. By providing entrepreneurs and small enterprises with access to affordable and high-quality prototype PCBs, they are catalyzing innovation and streamlining the time-to-market. With their advanced manufacturing capabilities, seamless collaboration with designers, and commitment to quality, these factories are shaping the future of electronics manufacturing and propelling industries towards exponential growth.

Top Single PCB Assembly Factories: What You Need to Know

Single PCB Assembly Factories (need to remove brand name) has made a significant impact in the PCB assembly industry with their state-of-the-art facilities and commitment to quality. The company, which was established in (need to remove the year), has quickly become a leader in the industry due to its advanced technology and dedication to providing high-quality PCB assembly services to their customers. With a focus on innovation and customer satisfaction, Single PCB Assembly Factories has been able to distinguish themselves from their competitors.The company's PCB assembly facilities are equipped with the latest machinery and technology, allowing them to meet the demands of their customers with precision and efficiency. Their team of highly skilled engineers and technicians are committed to delivering top-notch services, ensuring that every project is completed to the highest standard.Single PCB Assembly Factories specializes in single PCB assembly, offering a wide range of services such as PCB design, PCB fabrication, PCB assembly, and PCB testing. Their expertise and comprehensive services have made them a reliable partner for businesses in various industries, including telecommunications, medical devices, consumer electronics, automotive, and more.The company's commitment to quality is evident in their stringent quality control processes, ensuring that every PCB assembly meets the highest industry standards. With a focus on continuous improvement, Single PCB Assembly Factories strives to optimize their processes and stay at the forefront of technological advancements in the industry.In addition to their cutting-edge facilities and services, Single PCB Assembly Factories also places a high importance on environmental responsibility. The company adheres to strict environmental standards in their manufacturing processes, ensuring that their operations are sustainable and environmentally friendly.Furthermore, Single PCB Assembly Factories is dedicated to providing exceptional customer service, working closely with their clients to understand their specific requirements and deliver customized solutions. Their efficient project management and communication ensure that every project is executed seamlessly, meeting deadlines and exceeding expectations.As a testament to their excellence in the industry, Single PCB Assembly Factories has received various certifications and accreditations, highlighting their commitment to quality and performance. The company is also continuously investing in research and development to stay ahead of the curve and provide innovative solutions to their customers.With a strong dedication to quality, innovation, and customer satisfaction, Single PCB Assembly Factories has solidified its position as a leading PCB assembly provider. Their unwavering commitment to excellence and continuous improvement sets them apart in the industry, making them the go-to partner for businesses seeking reliable and high-quality PCB assembly services.In conclusion, Single PCB Assembly Factories has established itself as a frontrunner in the PCB assembly industry, delivering top-notch services, advanced technology, and unparalleled customer satisfaction. With a focus on quality, innovation, and environmental responsibility, the company continues to set new standards in the industry and remains a trusted partner for businesses seeking superior PCB assembly solutions.

Easily Perform PCB Assembly at Home: Step-by-Step Guide and Tips

Title: Pioneering PCB Assembly at Home Solution Revolutionizes Electronics ManufacturingIntroduction:In a groundbreaking move, an innovative electronics manufacturing company has introduced a transformative Printed Circuit Board (PCB) assembly solution that allows users to assemble PCBs from the comfort of their homes. This breakthrough has the potential to revolutionize the electronics industry, providing an accessible and user-friendly solution for electronics enthusiasts, DIYers, and even small-scale manufacturers.Offering a range of impressive features and capabilities, the PCB Assembly at Home solution redefines traditional manufacturing processes and elevates them to a whole new level. The advent of this technology is set to bring about tremendous opportunities for creativity, convenience, and cost-effectiveness.Revolutionizing the Industry:With the introduction of the PCB Assembly at Home solution, the electronics manufacturing industry is on the cusp of a technological revolution. This cutting-edge system enables individuals to assemble PCBs without the need for expensive manufacturing facilities or specialized equipment. The convenience of manufacturing PCBs at home highlights the democratization of electronics production, empowering both professionals and enthusiasts to bring their ideas to life.The Unique Features and Benefits:Powered by state-of-the-art software, the PCB Assembly at Home solution provides a user-friendly interface that guides users through the entire assembly process. The platform seamlessly integrates design, prototyping, and assembly, ensuring a streamlined experience. This breakthrough system eliminates the need for complex manual assembly, reducing the risk of human error and ultimately enhancing the overall quality of the PCBs produced.The versatility of this solution is another aspect that sets it apart. Users can assemble a wide range of PCB types, from simple designs to complex multi-layer boards, catering to diverse needs. The flexibility of this approach fosters innovation, allowing users to experiment with various components, test new designs, and refine their products swiftly.Furthermore, the ability to assemble PCBs at home significantly cuts down on logistics costs and time-consuming processes. Gone are the days of relying on external manufacturers and facing prolonged waiting periods. With this new solution, users save both time and money, giving them the freedom to let their creativity and problem-solving skills flourish.Application in various Industries:The PCB Assembly at Home solution opens up new avenues across multiple sectors, including consumer electronics, IoT devices, robotics, and automotive industries. This innovative approach not only benefits professional electronics manufacturers but also empowers individual entrepreneurs, allowing them to manufacture their own products with ease.Small-scale manufacturers, start-ups, and research laboratories can particularly benefit from this technology. By eliminating the need for outsourcing, they can significantly reduce production costs, accelerate time to market, and gain a competitive edge.Future Implications:The introduction of the PCB Assembly at Home solution brings us one step closer to a future where individuals and small-scale businesses have full control over the entire product development lifecycle. As this technology advances, we can expect further enhancements, such as increased automation, integration with AI algorithms, and connectivity with other manufacturing systems.This revolutionary solution has the potential to spark a wave of innovation, empower individuals, and reshape the current landscape of electronics manufacturing. PCB Assembly at Home ushers in a new era of accessibility, convenience, and cost-effectiveness, cementing its position as a game-changer in the industry.Conclusion:The PCB Assembly at Home solution signifies a monumental shift in the electronics manufacturing industry. With its groundbreaking features, user-friendly interface, and endless possibilities, it holds the promise of democratizing product development, lowering costs, and accelerating innovation. As this technology gains popularity, it is set to transform the way we perceive and drive electronics manufacturing, bringing the future of assembly directly into our homes.