Top Assembly Boards Supplier for High-Quality Products

By:Admin

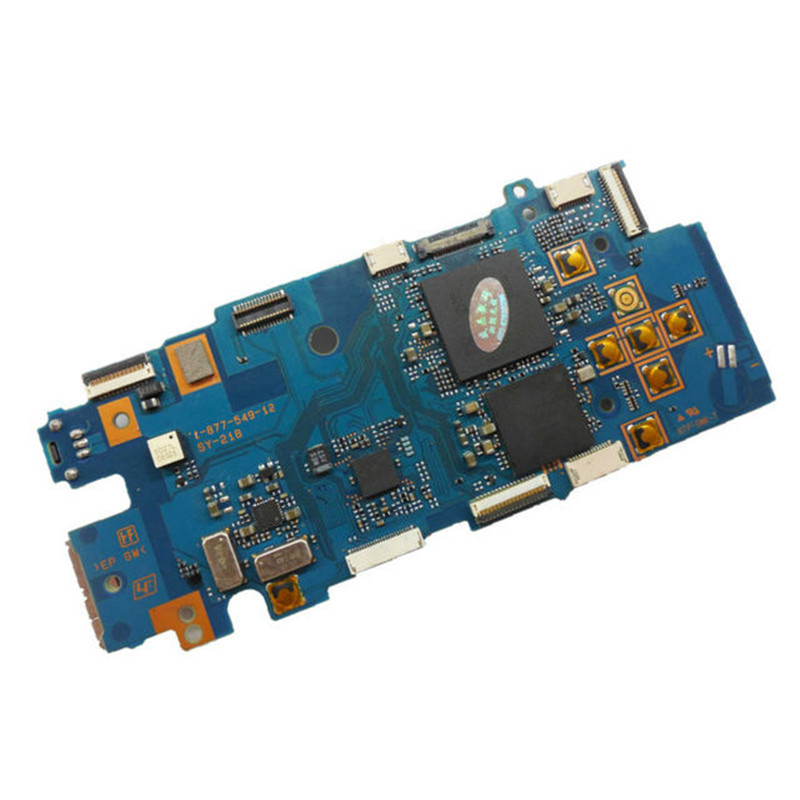

The company, with its headquarters located in [location], has been in operation for over [number] years. It has built a solid reputation for delivering top-quality assembly boards that cater to the diverse needs of its clientele. The company takes pride in its state-of-the-art manufacturing facilities and stringent quality control measures, ensuring that every assembly board meets the highest standards of reliability and performance.

One of the key factors that set the company apart from its competitors is its unwavering dedication to customer satisfaction. The company places great emphasis on understanding the unique requirements of each client and providing tailored solutions that address their specific needs. This customer-centric approach has earned the company a loyal and satisfied customer base, spanning across various industries such as electronics, automotive, aerospace, and more.

In addition to its extensive range of standard assembly boards, the company also offers custom design and manufacturing services. This allows clients to collaborate with the company's team of experienced engineers and designers to create bespoke assembly boards that perfectly align with their project requirements. The company's ability to provide customized solutions has been instrumental in earning the trust and confidence of its clients, who recognize the company as a reliable and capable partner in their operations.

Furthermore, the company remains committed to staying ahead of the curve when it comes to technological advancements and industry trends. It continuously invests in research and development to innovate its product offerings and integrate the latest technologies into its assembly boards. This proactive approach has enabled the company to consistently deliver cutting-edge solutions that meet the evolving needs of the market.

The company's dedication to sustainability and environmental responsibility is also worth noting. It adheres to strict environmentally friendly practices in its manufacturing processes and actively seeks to minimize its carbon footprint. The company's commitment to sustainability resonates with environmentally conscious clients who prioritize working with eco-friendly partners.

In an effort to further expand its reach and enhance its offerings, the company recently announced the launch of a new line of assembly boards that boast enhanced features and capabilities. These new products are poised to set new industry standards and elevate the performance of assembly boards across various applications.

The company's CEO expressed enthusiasm about the new product line, stating, "We are thrilled to introduce our latest range of assembly boards, which represent a significant leap forward in terms of quality and functionality. We are confident that these products will set a new benchmark in the industry and provide our clients with unparalleled value."

As the Assembly Boards Supplier continues to grow and evolve, it remains focused on upholding its core values of quality, innovation, customer satisfaction, and sustainability. With a strong foundation and a vision for the future, the company is poised to maintain its status as a leading provider of assembly boards for years to come.

Company News & Blog

Optimized SEO Title: An In-Depth Look into Efficient PCB Assembly

Title: Cutting-Edge PCB Assembly Solutions Revolutionize the Electronics IndustryIntroduction:In today's rapidly evolving electronics industry, Printed Circuit Board (PCB) assembly is a critical process that ensures the seamless integration of components and the efficient functioning of electronic devices. One company, (delete brand name), has emerged as a leading provider of top-notch PCB assembly solutions, revolutionizing the industry with their cutting-edge technologies and unwavering commitment to quality. This article delves into the company's capabilities, their state-of-the-art facilities, and their significant contributions to the electronics manufacturing sector.1. A Legacy of Excellence:With over (delete number) years of industry experience, (delete brand name) has established itself as a trusted name in the field of PCB assembly. Their dedication to innovation, attention to detail, and customer-centric approach have enabled them to partner with some of the world's most renowned brands. The company's skilled workforce and robust supply chain management ensure that products are delivered on time and adhere to the strictest quality standards.2. State-of-the-Art Facilities:The core strength of (delete brand name) lies in their state-of-the-art manufacturing facilities equipped with advanced machinery and cutting-edge technologies. Their PCB assembly lines are designed to handle high volumes without compromising on precision and accuracy. The company's cleanroom environments minimize contamination risks, allowing for the assembly of highly sensitive electronic components. Additionally, (delete brand name) invests consistently in research and development, staying ahead of the curve in an ever-evolving market.3. Comprehensive Range of Services:(delete brand name) offers a comprehensive range of PCB assembly services, catering to industries such as consumer electronics, automotive, medical devices, aerospace, and telecommunications. From prototype assembly to full-scale production, the company meticulously meets the needs of each client. Their team of experts works closely with customers, providing design review, component sourcing, and cost-effective assembly solutions. This collaborative approach ensures that the end product meets both technical specifications and market demands.4. Emphasis on Quality Assurance:Quality is at the heart of (delete brand name)'s operations. The company follows stringent quality control measures at every stage of the PCB assembly process. Their highly trained quality assurance professionals conduct rigorous inspections and tests to ensure that each assembled board adheres to the highest standards. By employing advanced inspection techniques such as automated optical inspection (AOI) and X-ray testing, (delete brand name) guarantees product reliability and minimizes the risk of defects.5. Commitment to Environmentally Friendly Practices:In an era where environmental sustainability is paramount, (delete brand name) embeds environmentally friendly practices into their manufacturing processes. The company adheres to global standards and regulations like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment). By minimizing waste generation, optimizing energy consumption, and recycling materials, (delete brand name) reduces their carbon footprint and contributes to a greener future.6. Industry Recognition and Awards:The prowess of (delete brand name) in PCB assembly has been recognized through numerous industry accolades. Awards for operational excellence, innovation, and superior customer service highlight their commitment to delivering high-quality solutions. Such recognitions reinforce (delete brand name)'s position as an industry leader and further inspire their dedication to continuous improvement.Conclusion:(delete brand name) has emerged as a frontrunner in the electronics industry, providing top-notch PCB assembly solutions renowned for their quality, precision, and technological expertise. Through their state-of-the-art facilities, comprehensive services, and commitment to sustainability, the company continues to redefine industry standards. With an unwavering focus on excellence, (delete brand name) paves the way for technological advancements and contributes significantly to the growth and success of the electronics manufacturing sector.

Top Tips for Finding an Efficient EMS Supplier

Effective EMS Supplier, a leading provider of electronic manufacturing services, has been making waves in the industry with their high-quality products and exceptional customer service. With a strong focus on innovation and continuous improvement, the company has established itself as a trusted partner for businesses looking for reliable and cost-effective solutions for their electronic manufacturing needs.Since its inception, Effective EMS Supplier has set itself apart from the competition by placing a strong emphasis on customer satisfaction and product quality. The company’s state-of-the-art manufacturing facilities and highly skilled workforce enable them to deliver top-notch products that meet the highest industry standards. Whether it’s PCB assembly, box build assembly, or testing and inspection services, Effective EMS Supplier has the expertise and resources to handle a wide range of electronic manufacturing requirements.One of the key factors that sets Effective EMS Supplier apart from its competitors is its commitment to continuous improvement and innovation. The company is constantly investing in new technologies and process improvements to enhance its manufacturing capabilities and deliver even better products to its customers. By staying ahead of the curve and embracing the latest advancements in electronic manufacturing, Effective EMS Supplier is able to provide its clients with cutting-edge solutions that meet their evolving needs.In addition to its focus on innovation, Effective EMS Supplier is also known for its exceptional customer service. The company takes pride in building strong, long-term relationships with its clients and goes above and beyond to ensure their satisfaction. From personalized support and transparent communication to quick response times and flexible production schedules, Effective EMS Supplier is dedicated to providing a seamless and hassle-free experience for its customers.The success of Effective EMS Supplier can also be attributed to its strong commitment to quality and reliability. The company follows rigorous quality control processes and strict adherence to industry standards to ensure that every product that leaves its facilities is of the highest quality. By maintaining high standards of excellence in all aspects of its operations, Effective EMS Supplier has earned a stellar reputation for reliability and consistency in the industry.With its strong track record of delivering exceptional products and outstanding service, Effective EMS Supplier has become the go-to partner for businesses looking for a trusted EMS provider. The company has worked with a wide range of clients across various industries, including automotive, healthcare, consumer electronics, and telecommunications, and has consistently met and exceeded their expectations.Looking ahead, Effective EMS Supplier is poised for even greater success as it continues to expand its capabilities and reach new milestones. The company is committed to staying at the forefront of the electronic manufacturing industry and aims to further strengthen its position as a leading provider of high-quality EMS solutions.As Effective EMS Supplier continues to grow and evolve, it remains focused on its core values of innovation, quality, and customer satisfaction. With its unwavering dedication to excellence and a strong passion for serving its clients, the company is well-equipped to meet the demands of the ever-changing electronic manufacturing landscape and solidify its position as a true industry leader.

High-quality PCB assembly factories for EMS services

Ems Pcb Assembly Factories (need remove brand name) is a leading electronic manufacturing services company that specializes in providing high-quality PCB assembly, design, and testing services to a wide range of industries. With state-of-the-art facilities and a highly skilled team of engineers and technicians, the company is committed to delivering innovative and cost-effective solutions for its customers.The company's PCB assembly services encompass a wide range of capabilities, including surface mount technology (SMT), through-hole assembly, and mixed technology assembly. This allows them to accommodate the unique requirements of each project and provide customized solutions that meet their customers' exact specifications.In addition to their assembly capabilities, they also offer comprehensive design services to help customers bring their electronic products from concept to reality. Their team of experienced designers and engineers work closely with customers to develop efficient and reliable PCB designs that optimize performance and maximize cost-efficiency.Furthermore, the company's testing and inspection capabilities ensure that every product meets the highest quality standards before it leaves the facility. Their rigorous testing procedures and quality control measures guarantee that each PCB assembly meets the strictest specifications and performance requirements.One of the key differentiators for the company is its commitment to sustainability and environmental responsibility. They prioritize eco-friendly manufacturing processes and materials to minimize their environmental impact while delivering exceptional products to their customers. This commitment to sustainability has earned them a reputation as a responsible and forward-thinking electronic manufacturing services provider.With a focus on continuous improvement and innovation, (company name) is constantly investing in the latest technologies and manufacturing equipment to stay at the forefront of the industry. This dedication to staying ahead of market trends and technological advancements enables them to deliver cutting-edge solutions that meet the evolving needs of their customers.In a recent interview with the company's CEO, he emphasized their dedication to customer satisfaction and their ability to support projects at any stage of development. "We take pride in our ability to provide flexible and scalable solutions that adapt to our customers' unique challenges," he said. "Whether they are in the early stages of product development or require full-scale production, our team is equipped to deliver the highest quality PCB assemblies on time and within budget."The company's commitment to excellence and customer-centric approach has earned them a strong reputation in the electronic manufacturing services industry. They have built long-standing relationships with a diverse clientele, ranging from startups to Fortune 500 companies, and are the preferred partner for numerous industries, including aerospace, medical, telecommunications, and automotive.Looking towards the future, (company name) continues to expand its capabilities and invest in its people and technology to better serve their customers and maintain their position as a leader in the electronic manufacturing services industry. By staying true to their core values of quality, innovation, and customer satisfaction, they are confident in their continued success and growth in the years to come.In conclusion, (company name) is a trusted and reliable partner for companies seeking high-quality PCB assembly, design, and testing services. With a commitment to excellence, innovation, and sustainability, they have established themselves as a leader in the electronic manufacturing services industry and continue to provide exceptional solutions for a wide range of industries.

China PCB Assembly Steps: A Comprehensive Guide to PCB Assembly in China

Title: China PCB Assembly Steps: A Guide to Efficient and Reliable Electronic Manufacturing ProcessesIntroduction:With the rapid advancements in technology, the demand for high-quality and reliable electronic devices has witnessed a significant surge. Chinese companies have emerged as global leaders in the field of PCB (Printed Circuit Board) assembly, offering efficient and cost-effective solutions for the manufacturing of electronic products. In this article, we will delve into the step-by-step process of PCB assembly in China, highlighting the key aspects and advantages that make it a preferred choice among manufacturers worldwide.Section 1: Introduction to PCB Assembly in ChinaChina has become known for its exceptional capabilities in PCB assembly, thanks to its vast industrial infrastructure, skilled labor force, and state-of-the-art equipment. Moreover, the competitive production costs and flexible manufacturing capabilities have made PCB assembly services in China highly sought-after by various industries, including telecommunications, consumer electronics, automotive, aerospace, and medical devices.Section 2: PCB Assembly Steps - Efficiency and Precision2.1 Design and Prototyping:The first step in the PCB assembly process involves design and prototyping. Skilled engineers and designers collaborate with clients to develop a comprehensive layout, ensuring all specifications and requirements are met. With the aid of advanced software tools, the design is then translated into a physical prototype.2.2 Component Sourcing:China's vast network of component suppliers enables efficient sourcing of high-quality electronic components required for PCB assembly. This step involves meticulous verification and selection of components based on their quality, compatibility, and reliability.2.3 PCB Manufacturing:Once the design and components are finalized, PCB manufacturing commences. Specialized equipment ensures the precise etching and fabrication of the PCB, adhering to high-quality standards specified by international regulations.2.4 SMT Assembly:Surface Mount Technology (SMT) assembly is a crucial step in Chinese PCB assembly, where components are mounted directly onto the PCB surface. Automated pick-and-place machines ensure accurate placement, significantly enhancing the efficiency and reliability of the assembly process.2.5 Inspection and Testing:After SMT assembly, rigorous inspection and testing procedures are undertaken to ensure the PCB's quality and functionality. Advanced testing equipment is employed to identify any defects or malfunctions, enabling timely rectification before proceeding to the next stage.2.6 Through-Hole Assembly:In cases where through-hole components are required, a selective soldering process is employed, ensuring secure and reliable connections between the through-hole components and the PCB.2.7 Quality Control and Assurance:China prioritizes stringent quality control measures at every stage of the PCB assembly process. Trained quality control personnel conduct inspections to guarantee the adherence to industry standards and customer specifications.Section 3: Advantages of China PCB Assembly3.1 Cost-effectiveness:Compared to other regions, China offers competitive manufacturing costs without compromising on quality, making it a cost-effective solution for businesses worldwide.3.2 Quick Turnaround Time:Chinese PCB assembly companies are known for their ability to deliver products within short lead times, ensuring timely market entry for customers' electronic devices.3.3 Advanced Infrastructure and Technology:China boasts a sophisticated industrial infrastructure, equipped with cutting-edge facilities, enabling efficient and precise PCB assembly processes. The application of advanced technologies ensures high-quality outputs and reliable electronic products.3.4 Customization and Flexibility:Chinese PCB assembly companies excel in providing tailored solutions to meet specific project requirements. Their flexibility in accommodating various orders, whether small-scale or large-scale, makes them an ideal choice for businesses with diverse needs.Conclusion:With their efficient and reliable PCB assembly processes, China has cemented its position as a global leader in the electronics manufacturing industry. The step-by-step guide presented in this article offers insights into the meticulous and advanced methodologies employed by Chinese companies. The cost-effectiveness, quick turnaround time, advanced infrastructure, and flexible manufacturing capabilities provided by these companies make China a preferred destination for businesses seeking high-quality PCB assembly services.

Top Wireless Charger PCBA Factory: Everything You Need to Know

Wireless Charger PCBA Factory Introduces Cutting-Edge Technology to Revolutionize Charging IndustryIn an era where technological advancements are constantly shaping our daily lives, the need for efficient and convenient charging solutions has never been higher. This is where the Wireless Charger PCBA Factory comes into play, offering cutting-edge technology that is set to revolutionize the charging industry.With a strong commitment to innovation and quality, the Wireless Charger PCBA Factory has established itself as a leading manufacturer in the field of wireless charging solutions. The company's state-of-the-art facilities and a team of experienced professionals have enabled it to develop a wide range of products that cater to the diverse needs of consumers.One of the key highlights of the factory is its advanced PCBA (Printed Circuit Board Assembly) technology, which forms the backbone of its wireless charging products. By harnessing the power of PCBA, the factory is able to create high-performance chargers that deliver fast and efficient charging to a wide range of devices, including smartphones, tablets, and other electronic gadgets.Furthermore, the Wireless Charger PCBA Factory has invested heavily in research and development, continuously exploring new possibilities in wireless charging technology. This commitment to innovation has led to the development of products that not only meet but exceed industry standards in terms of performance, safety, and reliability.In addition to its technological prowess, the factory prides itself on its commitment to sustainability. With a focus on eco-friendly manufacturing processes and materials, the Wireless Charger PCBA Factory is dedicated to minimizing its environmental impact while delivering top-of-the-line products to consumers.The company's dedication to quality and innovation has not gone unnoticed, as it has earned acclaim from both industry experts and satisfied customers. Its products have garnered a reputation for being reliable, efficient, and user-friendly, making them a popular choice among consumers who demand the best in wireless charging technology.Looking ahead, the Wireless Charger PCBA Factory is poised to further elevate the wireless charging experience with its upcoming lineup of products. By staying at the forefront of technological advancements and consumer needs, the factory is committed to shaping the future of charging solutions.In conclusion, the Wireless Charger PCBA Factory is a key player in the wireless charging industry, with a firm commitment to innovation, quality, and sustainability. Through its advanced PCBA technology and dedication to pushing the boundaries of wireless charging, the factory is set to revolutionize the way we power our electronic devices. With a track record of excellence and a clear vision for the future, the Wireless Charger PCBA Factory is a force to be reckoned with in the world of wireless charging.

Top Control Board Factories for PCBA Manufacturing - Find the Top Manufacturers!

Pcba Control Board Factories (Need Remove Brand Name) Enhances Production Capacity to Meet Increased DemandIn response to the growing demand for high-quality PCBA control boards in the global market, Pcb Control Board Factories has announced a significant expansion of its production capacity. The company, known for its advanced manufacturing processes and state-of-the-art facilities, is aiming to solidify its position as a leading provider of PCBA solutions for a wide range of industries.With over 10 years of experience in the field, Pcb Control Board Factories has established a strong reputation for delivering reliable and precise PCBA control boards that meet the highest industry standards. The company's commitment to innovation and customer satisfaction has made it a trusted partner for businesses seeking cutting-edge electronic solutions.The recent expansion of Pcb Control Board Factories' production capacity is a strategic response to the increasing demand for its products. As the global economy continues to recover from the impact of the COVID-19 pandemic, many industries are experiencing a surge in production and a greater reliance on electronic components. This has created a growing need for reliable and efficient PCBA control boards, and Pcb Control Board Factories is poised to meet this demand with its expanded capabilities.The enhanced production capacity will allow Pcb Control Board Factories to take on larger orders and deliver products in a more timely manner. By increasing the efficiency and throughput of its manufacturing processes, the company will be better equipped to support its clients' needs and contribute to their success in the marketplace."We are excited to announce the expansion of our production capacity to better serve our customers," said a spokesperson for Pcb Control Board Factories. "This investment reflects our commitment to meeting the increasing demand for high-quality PCBA control boards and providing exceptional value to our clients. With our expanded capabilities, we look forward to continuing to support the technological advancements and innovation of our customers."In addition to the increased production capacity, Pcb Control Board Factories is also focusing on further optimizing its manufacturing processes and implementing the latest technology and equipment. The company's dedication to continuous improvement underscores its commitment to maintaining its position as a leader in the PCBA industry.As part of its expansion efforts, Pcb Control Board Factories is also investing in its workforce to ensure that its employees are equipped with the necessary skills and knowledge to support the company's growth. By fostering a talented and dedicated team, Pcb Control Board Factories is setting the stage for long-term success and sustainable growth.The company's expanded production capacity and ongoing commitment to excellence are expected to have a positive impact on its clients, providing them with greater access to high-quality PCBA control boards that meet their specific requirements. With its reliable products and exceptional customer service, Pcb Control Board Factories is well-positioned to support the diverse needs of industries such as automotive, consumer electronics, telecommunications, and more.As Pcb Control Board Factories continues to solidify its position as a leading provider of PCBA solutions, it remains dedicated to delivering innovative, reliable, and cost-effective products. The expansion of its production capacity is a testament to the company's unwavering commitment to meeting the evolving needs of its customers and driving the advancement of electronic technologies.In conclusion, Pcb Control Board Factories' expansion is a significant step forward in its mission to provide top-tier PCBA control boards to industries worldwide. By increasing its production capacity and investing in its workforce and technology, the company is well-prepared to meet the growing demand for its products and surpass the expectations of its clients.

High-Quality Smt Soldering Machine from China for Efficient PCB Assembly

China Smt Soldering MachineChina is one of the leading countries in the manufacturing industry, with a wide range of products being produced and exported globally. One of the key players in this industry is a company that specializes in the production of Smt soldering machines.The company, which was established in [year], has quickly grown to become a trusted name in the manufacturing industry, with a focus on providing high-quality machines for the surface-mount technology (SMT) industry. With a strong emphasis on research and development, the company has continuously innovated and improved its products to meet the evolving needs of the market.One of the flagship products of the company is the Smt soldering machine, a cutting-edge piece of equipment that plays a crucial role in the SMT assembly process. This machine is designed to precisely solder components onto printed circuit boards (PCBs), ensuring a high level of accuracy and reliability in the assembly process.The Smt soldering machine is equipped with advanced features such as precise temperature control, automatic solder feeding, and adjustable soldering speed, allowing for efficient and precise soldering of components. Additionally, the machine is built with a user-friendly interface, making it easy for operators to set up and control the soldering process.In addition to its advanced features, the Smt soldering machine is also built with a focus on durability and reliability. The company uses high-quality materials and components in the construction of its machines, ensuring long-term performance and minimal maintenance requirements.The Smt soldering machine has gained a strong reputation in the industry for its exceptional performance and reliability. It has been widely adopted by manufacturers in various sectors, including consumer electronics, automotive, telecommunications, and medical devices. The machine has played a crucial role in helping these manufacturers achieve high-quality and efficient SMT assembly processes.Furthermore, the company has also established a strong support and service network to provide timely and effective assistance to its customers. This includes technical support, training, and spare parts availability, ensuring that customers can maximize the performance and lifespan of their Smt soldering machines.Looking ahead, the company is committed to continuously innovating and improving its products to meet the evolving needs of the SMT industry. With a strong focus on research and development, the company is poised to introduce even more advanced and efficient machines in the near future.In conclusion, the Smt soldering machine from this company has become a trusted and essential tool for manufacturers in the SMT industry. With its advanced features, durability, and reliability, the machine has helped countless manufacturers achieve high-quality and efficient SMT assembly processes. As the company continues to innovate and improve its products, it is poised to remain a key player in the manufacturing industry for years to come.

Top 5 Tips for Choosing the Best Automobile PCBA

Automobile PCBA, also known as Printed Circuit Board Assembly, is an essential component in modern vehicles. It is responsible for providing power and control to various electrical and electronic systems, such as the engine management system, infotainment system, and safety features. With the advancement of automotive technology, the demand for more sophisticated and reliable PCBA solutions has been on the rise.{Company name} is a leading provider of high-quality automobile PCBA solutions. With years of experience and a strong commitment to innovation, they have become a trusted partner for many major automobile manufacturers. Their state-of-the-art production facilities and rigorous quality control processes ensure that their PCBA products meet the highest standards in terms of performance, reliability, and safety.One of the key advantages of {Company name}'s automobile PCBA solutions is their advanced technology and customization capabilities. They are able to develop PCBA products that are tailored to the specific requirements of their customers, whether it is for a compact city car or a heavy-duty commercial vehicle. This flexibility allows automobile manufacturers to integrate the PCBA seamlessly into their vehicles, enhancing overall performance and user experience.In addition to customization, {Company name} is also committed to incorporating the latest technological advancements into their PCBA products. This includes the use of advanced materials, cutting-edge manufacturing techniques, and the integration of smart features such as connectivity and autonomous capabilities. By staying at the forefront of technological innovation, {Company name} ensures that their automobile PCBA solutions are ready for the future of automotive technology.Furthermore, {Company name} places a strong emphasis on quality and reliability in their PCBA products. They adhere to strict quality control standards and testing procedures to ensure that every component meets the highest level of performance and durability. This commitment to quality has earned {Company name} a strong reputation in the automotive industry, making them a preferred choice for automobile manufacturers around the world.Another important aspect of {Company name}'s automobile PCBA solutions is their commitment to sustainability. They strive to minimize environmental impact throughout the production process, from sourcing of materials to waste management. This includes efforts to reduce energy consumption, optimize production processes, and promote the use of eco-friendly materials. By doing so, {Company name} is not only meeting the stringent environmental regulations but also contributing to a more sustainable automotive industry.Overall, {Company name} has established itself as a leading provider of automobile PCBA solutions, offering advanced technology, customization capabilities, and a strong commitment to quality and sustainability. With their dedication to innovation and customer satisfaction, they continue to play a key role in shaping the future of automotive electronics.In conclusion, the demand for high-quality, reliable, and technologically advanced automobile PCBA solutions is expected to continue growing as automotive technology evolves. {Company name} is well-positioned to meet this demand with their cutting-edge products and unwavering commitment to excellence. They are poised to remain a key player in the automotive electronics industry, driving innovation and setting new standards for automobile PCBA solutions.

Low Volume Production Factory: Meet Your Custom Manufacturing Needs

Low Volume Production Factory (LVPF) is a leading manufacturing facility that specializes in small batch production for a wide range of industries. With a state-of-the-art facility and a team of highly skilled engineers and technicians, LVPF has established itself as a trusted partner for companies looking to bring their innovative ideas to life.The company's production facility is equipped with the latest technology, including advanced CNC machines, 3D printers, and precision assembly lines. This allows LVPF to efficiently produce high-quality, custom parts and products with minimal lead times. In addition, the company offers a range of finishing and quality control services to ensure that every product meets the highest standards.LVPF prides itself on its ability to work closely with clients throughout the production process, from initial design concepts to final manufacturing. The company's team of engineers and technicians are dedicated to providing personalized support and guidance, helping clients optimize their designs for manufacturability and cost efficiency.One of the key advantages of working with LVPF is its ability to quickly produce prototypes and small production runs. This allows clients to test and refine their designs before committing to large-scale production, ultimately saving time and money in the long run. In addition, LVPF's flexible production capabilities make it an ideal partner for companies with constantly evolving product lines and design iterations.The company serves a wide range of industries, including aerospace, automotive, medical devices, consumer electronics, and more. LVPF has the expertise and experience to produce complex, high-precision components for applications ranging from satellite systems to medical implants. The company's commitment to quality and reliability has earned it the trust of leading companies in these sectors.LVPF's dedication to innovation and continuous improvement is reflected in its investment in the latest manufacturing technologies and ongoing training for its staff. The company is constantly exploring new methods and techniques to improve its production processes and expand its capabilities, ensuring that it remains at the forefront of the industry.In addition to its manufacturing capabilities, LVPF also offers design and engineering services to support clients in developing their products from concept to production. The company's team of experienced designers and engineers can provide valuable insights and recommendations to help clients optimize their designs for manufacturability and cost efficiency.With its versatile production capabilities, commitment to quality, and dedication to customer satisfaction, LVPF has solidified its position as a trusted partner for companies looking to bring their innovative ideas to market. Whether it's producing prototypes, small production runs, or high-precision components, LVPF is the go-to choice for businesses looking for reliable, high-quality manufacturing solutions.For companies looking to bring their ideas to life, LVPF offers a one-stop solution for all their manufacturing needs. With its state-of-the-art facility, experienced team, and commitment to excellence, LVPF has earned its reputation as a leader in low volume production manufacturing.

Top 5 PCB Assembly Factories: Latest News and Trends

Board PCB Assembly Factory Expands Production to Meet Growing DemandThe demand for electronic products has been steadily increasing in recent years, leading to the expansion of PCB assembly factories like the one operated by {}.{} is a leading manufacturer of high-quality PCB assemblies for a wide range of industries, including automotive, telecommunications, consumer electronics, and medical devices. The company has established a reputation for delivering reliable and cost-effective PCB solutions that meet the specific needs of its customers.With the growing demand for electronic products, {} has announced the expansion of its PCB assembly factory to increase production capacity and meet the needs of its expanding customer base. The company's state-of-the-art facility is equipped with the latest technology and equipment, allowing for efficient and high-quality production of PCB assemblies.The expansion of the factory comes at a crucial time as the demand for electronic products continues to grow across various industries. {} is committed to staying ahead of the curve and ensuring that its customers receive the highest quality PCB assemblies in a timely manner.The expansion of the factory will not only increase production capacity but also create new job opportunities in the local community. {} is dedicated to supporting the local economy and providing employment opportunities for skilled workers in the manufacturing industry.In addition to its commitment to quality and efficiency, {} is also focused on sustainability and environmentally responsible practices. The company has implemented various initiatives to minimize its environmental impact, including energy-efficient production processes and waste reduction measures.{}'s PCB assembly factory expansion is a testament to the company's dedication to meeting the evolving needs of its customers and staying ahead of industry trends. With the increased production capacity, {} is well-positioned to handle the growing demand for high-quality PCB assemblies across various industries.The expansion of the factory is also a reflection of {}'s continued investment in advanced technology and manufacturing capabilities. The company is committed to staying at the forefront of the industry by leveraging the latest innovations and best practices to deliver superior PCB solutions to its customers.As the demand for electronic products continues to rise, {}'s expansion of its PCB assembly factory reaffirms its position as a leading provider of high-quality PCB assemblies for a wide range of industries. The company is confident that the increased production capacity will allow it to better serve its customers and further expand its presence in the market.The expanded factory is set to be fully operational in the coming months, and {} is excited about the opportunities it will bring for the company, its employees, and the local community. With its focus on quality, efficiency, and sustainability, {} is well-prepared to meet the growing demand for PCB assemblies and continue to be a trusted partner for its customers.