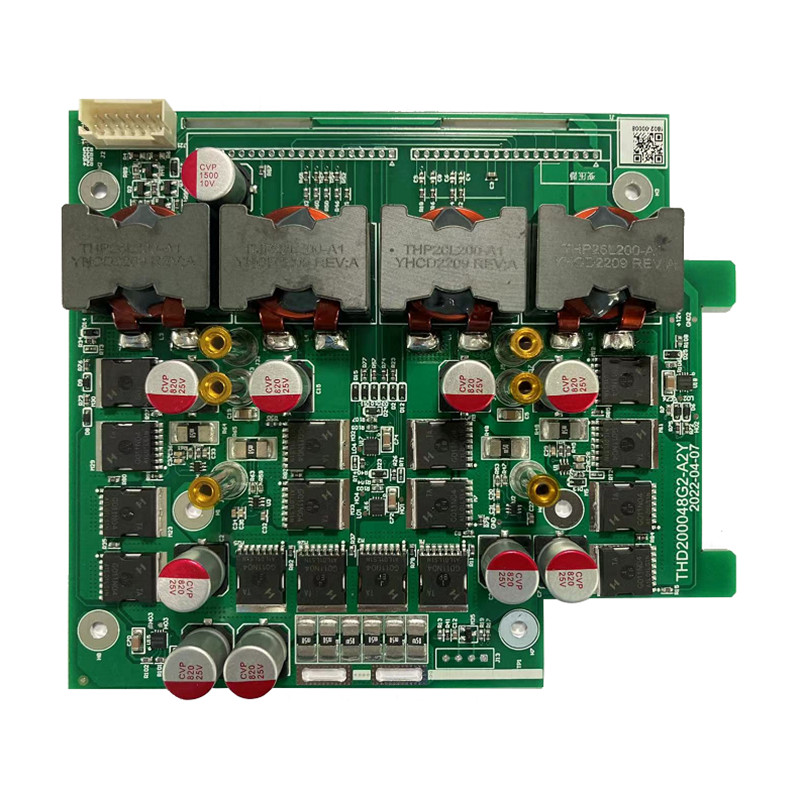

Top Quality PCB Assembly Factory for Main Assembly Components

By:Admin

[City], [Date] – [Main PCB Assembly Factory] is proud to announce its 20th anniversary as a leading provider of comprehensive PCB assembly solutions for a wide range of industries. Since its inception in [year], the company has been dedicated to delivering high-quality products and exceptional customer service, earning a reputation as a trusted and reliable partner in the electronics manufacturing industry.

With state-of-the-art facilities and a team of experienced professionals, [Main PCB Assembly Factory] has continuously innovated and adapted to meet the evolving needs of its clients. The company offers a complete range of services, including PCB assembly, surface mount technology (SMT), through-hole assembly, testing, and packaging. Whether it’s a prototype, low volume, or high volume production, [Main PCB Assembly Factory] has the capabilities to handle projects of any size and complexity.

One of the key factors behind the success of [Main PCB Assembly Factory] is its commitment to investing in the latest technology and equipment. The company’s manufacturing facilities are equipped with advanced machinery and tools, allowing for precision and efficiency in the assembly process. Additionally, [Main PCB Assembly Factory] adheres to strict quality control measures to ensure that all products meet the highest standards of performance and reliability.

Another crucial aspect of [Main PCB Assembly Factory]’s success is its focus on customer satisfaction. The company takes a collaborative approach with its clients, working closely with them to understand their specific requirements and deliver tailored solutions. Whether it’s a new product development or a redesign of an existing PCB, [Main PCB Assembly Factory] is dedicated to providing cost-effective and reliable services.

In addition to its technical capabilities, [Main PCB Assembly Factory] takes pride in its commitment to sustainability and environmental responsibility. The company adheres to strict environmental regulations and strives to minimize its impact on the environment through green manufacturing practices. This includes the use of eco-friendly materials, energy-efficient processes, and waste reduction initiatives.

“We are incredibly proud to celebrate 20 years of innovation and excellence in the PCB assembly industry,” said [Spokesperson], CEO of [Main PCB Assembly Factory]. “Since our inception, we have remained committed to delivering high-quality products and exceptional customer service to our clients. This milestone is a testament to the hard work and dedication of our team, as well as the trust and support of our valued customers.”

Looking ahead, [Main PCB Assembly Factory] is dedicated to furthering its position as a leader in the electronics manufacturing industry. The company continues to invest in research and development, exploring new technologies and methodologies to enhance its capabilities and offerings. Additionally, [Main PCB Assembly Factory] is focused on expanding its reach and establishing new partnerships to better serve its global customer base.

As [Main PCB Assembly Factory] looks to the future, the company remains steadfast in its commitment to excellence, innovation, and customer satisfaction. With a strong foundation built over the past two decades, [Main PCB Assembly Factory] is poised to continue its success and make significant contributions to the electronics manufacturing industry for years to come.

For more information about [Main PCB Assembly Factory] and its comprehensive PCB assembly solutions, please visit [website] or contact [contact information].

[Contact Information]

Company News & Blog

Exploring the Pros and Cons of Prototype PCB Board Factories

Title: Prototype PCB Board Factories Revolutionize Electronics Manufacturing IndustryIntroduction:In a rapidly evolving technology landscape, prototype PCB board factories have emerged as a crucial component of the electronics manufacturing sector. By facilitating the production of prototype printed circuit boards (PCBs), these factories are revolutionizing the industry by accelerating the product development cycle, reducing time-to-market, and bringing innovation within reach of entrepreneurs and small enterprises.The Role of Prototype PCB Board Factories:Prototype PCB board factories serve as a bridge between design and mass production. With state-of-the-art manufacturing capabilities and expertise, they transform innovative ideas into functional prototypes. Through an integrated approach that encompasses design optimization, material selection, and fast prototyping, these factories ensure the rapid realization of an idea into a physical, testable product. Simultaneously, they help identify potential design flaws, ensuring the final product is highly reliable and meets the desired specifications.The Manufacturing Process:Prototype PCB board factories employ cutting-edge technology, automated machinery, and precise quality control measures to streamline the manufacturing process. Surface-mount technology (SMT) allows for the mounting of electronic components directly onto the PCB, enhancing efficiency and minimizing manufacturing costs. Furthermore, the use of surface-mount technology enables the creation of smaller and more compact PCBs, ideal for modern electronic devices.Advanced software tools such as Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) enable seamless collaboration between design engineers and the factory. These tools ensure the accurate translation of design files into manufacturing instructions, guaranteeing a precise replication of the product envisioned by the designer.The Impact on Time-to-Market:Historically, developing a prototype PCB could be a lengthy and costly process, hindering innovation and delaying time-to-market. However, with the rise of prototype PCB board factories, this process has been significantly accelerated. From the initial design to manufacturing the first working PCB, the time required has been drastically reduced, allowing innovators to iterate and refine their designs rapidly. This shortened development cycle fosters innovation and enables companies to respond swiftly to market demands.Enabling Entrepreneurs and Small Enterprises:Prototype PCB board factories have leveled the playing field for entrepreneurs and small enterprises seeking to bring their innovative products to market. Traditionally, the cost associated with producing a prototype has been a significant barrier to entry for many aspiring innovators. However, the availability of affordable, high-quality prototype PCBs has empowered entrepreneurs, giving them the opportunity to transform their ideas into tangible products without having to make substantial upfront investments. This democratization of the manufacturing process has fueled the growth of start-ups and nurtured a vibrant ecosystem of innovators.Ensuring Quality and Reliability:Prototype PCB board factories prioritize the quality and reliability of the manufactured prototypes. These factories employ stringent quality control measures at every step of the manufacturing process. Automated optical inspection (AOI), X-ray inspection, and flying probe testing are just a few of the techniques employed to guarantee that the final product adheres to the highest industry standards. By conducting extensive testing and verification before the mass production phase, manufacturers can identify any potential issues, rectify them, and deliver reliable prototypes to their clients.Looking Towards the Future:The increasing demand for technologically advanced products, coupled with the emergence of disruptive technologies such as the Internet of Things (IoT), artificial intelligence (AI), and 5G, emphasizes the necessity for agile and efficient prototype PCB board factories. These factories are well-positioned to support the growth of industries spanning from healthcare to automotive and from smart cities to consumer electronics.In conclusion, prototype PCB board factories are playing a pivotal role in transforming the electronics manufacturing industry. By providing entrepreneurs and small enterprises with access to affordable and high-quality prototype PCBs, they are catalyzing innovation and streamlining the time-to-market. With their advanced manufacturing capabilities, seamless collaboration with designers, and commitment to quality, these factories are shaping the future of electronics manufacturing and propelling industries towards exponential growth.

Pcb Assembly Services for Surface Mount Technology

The demand for electronic devices continues to grow, with consumers seeking smaller, more powerful, and more efficient products. To meet this demand, {} has announced the launch of their new surface mount PCB assembly, providing customers with advanced technology and high-quality assembly services.{} is a leading provider of electronic manufacturing services, offering a wide range of solutions for businesses in various industries. With a focus on innovation and customer satisfaction, {} has established itself as a trusted partner for companies seeking reliable and cost-effective electronic manufacturing solutions.The new surface mount PCB assembly is designed to meet the growing demand for compact and high-performance electronic devices. By utilizing state-of-the-art technology and advanced assembly techniques, {} is able to deliver PCBs that are smaller, lighter, and more efficient than traditional through-hole assembly methods.One of the key advantages of surface mount PCB assembly is its ability to accommodate increasingly complex designs. With the growing trend towards miniaturization, electronic devices are becoming smaller and more compact. Surface mount technology allows for the placement of components directly onto the surface of the PCB, making it possible to create smaller and more densely populated circuit boards without sacrificing performance.In addition to its size advantages, surface mount PCB assembly also offers improved performance and reliability. By eliminating the need for drilled holes and the use of leads, surface mount technology reduces the risk of mechanical failures and improves the overall electrical performance of the PCB. This makes it an ideal choice for applications that require high-speed and high-frequency operation.Furthermore, {}'s surface mount PCB assembly process is highly automated, allowing for increased efficiency and cost savings. By utilizing advanced pick-and-place machines and reflow soldering techniques, {} is able to achieve higher levels of precision and consistency in the assembly process. This results in higher-quality PCBs with fewer defects, ultimately saving time and money for their customers.With the launch of their new surface mount PCB assembly, {} is well-positioned to meet the evolving needs of the electronic manufacturing industry. By leveraging their expertise and state-of-the-art facilities, {} is able to provide customers with cutting-edge assembly solutions that are tailored to their specific requirements.As a leading provider of electronic manufacturing services, {} is committed to delivering exceptional value to their customers. Whether it's through their advanced assembly capabilities, innovative solutions, or dedicated customer support, {} strives to exceed expectations and establish long-lasting partnerships with their clients.In conclusion, the launch of {}'s new surface mount PCB assembly represents a significant milestone in the company's commitment to innovation and excellence. By offering advanced technology, high-quality assembly services, and exceptional value, {} is poised to continue serving as a trusted partner for businesses in need of reliable electronic manufacturing solutions.

Discover the Leading Source for High-Quality PCB Assembly Services

Title: One-Stop PCB Assembly Supplier Streamlines Manufacturing Process to Meet Industry DemandsIntroduction:In an era marked by unprecedented technological advancements, the demand for printed circuit boards (PCBs) has skyrocketed across various industries. To address this growing need, an industry-leading PCB assembly supplier has emerged as a pioneer in the field, offering comprehensive services to meet the electronic manufacturing requirements of companies worldwide. This news article will delve deep into the workings of this one-stop solution provider and explore how they have revolutionized the industry with their efficient manufacturing processes.Company Overview:With a vision to provide cutting-edge PCB assembly services, the company has quickly risen to prominence as a top-tier supplier in the industry. Renowned for its unwavering commitment to quality, innovation, and customer satisfaction, the company has amassed a loyal client base that spans multiple sectors, including automotive, aerospace, telecommunications, and consumer electronics.Streamlined Manufacturing Process:The success of this one-stop PCB assembly supplier can be primarily attributed to its streamlined manufacturing process, which ensures maximum efficiency without compromising on quality. By blending the latest technological advancements with a skilled workforce, the company has perfected the art of PCB manufacturing, meeting the stringent demands of the modern market.Advanced Facilities and Equipment:At the core of the company's operational excellence lies state-of-the-art facilities and cutting-edge equipment that aid in the flawless production of PCBs. The supplier has made substantial investments in upgrading their infrastructure, allowing them to handle projects of various complexities with ease. Equipped with advanced automated machinery, precision instruments, and high-quality materials, the company guarantees robust PCB assembly that meets international standards.Experienced Engineering Team:Behind the scenes, a team of highly experienced engineers play a crucial role in the success of the PCB assembly process. These experts possess a wealth of technical knowledge and expertise and work collaboratively with clients to design and develop PCBs that meet their specific requirements. With their meticulous attention to detail and focus on continuous improvement, the engineering team ensures that every PCB leaving the facility is of exceptional quality and reliability.Quality Assurance Measures:As reliability is a critical factor in the electronic manufacturing industry, the company has implemented rigorous quality assurance measures at every stage of the production process. From stringent material inspections to thorough testing and validation procedures, the supplier leaves no stone unturned to deliver faultless PCB assemblies. Furthermore, the company adheres to industry standards, certifications, and compliance regulations, imparting an added layer of trust among their clientele.Customization and Flexibility:Recognizing the diverse needs of their customers, the one-stop supplier offers a high degree of customization and flexibility in their services. With the capacity to handle both small-scale production runs and large-scale manufacturing projects, the company caters to organizations of all sizes. Through open communication channels, the company ensures that each client's unique specifications are met, fostering long-term partnerships based on trust and reliability.Global Reach and Timely Delivery:Operating on a global scale, the supplier has established a robust supply chain network that enables them to serve clients across continents. With strategically located and fully equipped manufacturing facilities, the company guarantees expedited delivery times without compromising quality. This global reach positions the one-stop PCB assembly supplier as a preferred choice for multinational companies seeking efficient and reliable manufacturing solutions.Conclusion:In an increasingly competitive market, this one-stop PCB assembly supplier has emerged as a game-changer, revolutionizing the manufacturing process and meeting the dynamic demands of various industries. With their technologically advanced facilities, skilled workforce, commitment to quality, and global reach, the company continues to build a strong reputation as a leader in the field. As the demand for PCB assemblies continues to grow, this supplier is well-positioned to play a pivotal role in shaping the electronic manufacturing landscape for years to come.

Complete Guide to Surface Mount PCB Assembly Services

[Company Name] Announces Expansion of Surface Mount PCB Assembly[City, State] – [Date] – [Company Name], a leading provider of electronic manufacturing services, is excited to announce the expansion of its surface mount PCB assembly capabilities. With the investment in state-of-the-art equipment and technology, [Company Name] is poised to meet the growing demand for high-quality, reliable PCB assembly services.[Company Name] has been at the forefront of electronic manufacturing for over [number] years, specializing in offering innovative solutions to meet the evolving needs of its customers. The expansion of its surface mount PCB assembly capabilities is a testament to the company's commitment to staying ahead of the curve and providing its clients with the latest and most advanced manufacturing capabilities.The new equipment and technology introduced by [Company Name] will allow for precision placement of surface mount components on PCBs, resulting in improved accuracy, reliability, and efficiency. This will enable [Company Name] to offer a wider range of PCB assembly services to its customers, catering to a diverse set of needs and requirements."We are thrilled to announce the expansion of our surface mount PCB assembly capabilities," said [Spokesperson] of [Company Name]. "This investment represents our dedication to providing our customers with the highest quality manufacturing services. With the latest equipment and technology at our disposal, we can ensure that our PCB assembly processes are more advanced than ever, resulting in superior products for our clients."The expanded surface mount PCB assembly capabilities at [Company Name] will benefit a wide range of industries, including aerospace, automotive, consumer electronics, medical devices, and more. The company is well-positioned to serve the needs of clients in these sectors, delivering solutions that meet their specific requirements and standards.In addition to the expansion of its surface mount PCB assembly capabilities, [Company Name] continues to emphasize its commitment to quality, reliability, and customer satisfaction. The company adheres to strict quality control measures throughout the manufacturing process, ensuring that every product that leaves its facility meets the highest standards of excellence.Furthermore, [Company Name] takes a customer-centric approach to its services, working closely with clients to understand their unique needs and preferences. This collaborative approach allows [Company Name] to offer tailored solutions that address the specific challenges and goals of each customer, fostering strong and long-lasting partnerships.As [Company Name] continues to expand its surface mount PCB assembly capabilities, the company remains dedicated to staying at the forefront of electronic manufacturing. By investing in the latest technology and equipment, [Company Name] is well-equipped to meet the evolving demands of the industry and provide its customers with the most advanced and reliable solutions available.To learn more about [Company Name] and its electronic manufacturing services, visit [company website] or contact the company directly at [contact information].About [Company Name]:[Company Name] is a leading provider of electronic manufacturing services, specializing in PCB assembly, prototyping, testing, and more. With over [number] years of experience, [Company Name] is committed to delivering innovative and reliable solutions to meet the unique needs of its customers. The company's state-of-the-art facility and dedicated team of professionals ensure the highest levels of quality and customer satisfaction.

Introduction to Chip On Board Wire Bonding: All You Need to Know

Chip On Board Wire Bonding Technology Advancing in Semiconductor ManufacturingIn the fast-paced world of semiconductor manufacturing, innovative technologies are constantly emerging to enhance efficiency, reduce costs, and improve performance. One such advancement is Chip On Board (COB) wire bonding, a cutting-edge method that is revolutionizing the industry. This technology, combined with the expertise and experience of {Company Name}, is poised to make a significant impact on the semiconductor market.{Company Name}, a leading provider of semiconductor packaging and testing solutions, is at the forefront of the COB wire bonding revolution. With over {number} years of experience in the industry and a track record of delivering high-quality solutions, {Company Name} is well-positioned to leverage COB wire bonding technology to meet the evolving needs of semiconductor manufacturers.COB wire bonding is a process that involves directly connecting a semiconductor die to a substrate without the use of a package. This method offers numerous advantages over traditional packaging methods, including a smaller form factor, improved thermal performance, and lower overall cost. As the demand for smaller, more powerful electronic devices continues to grow, COB wire bonding is becoming increasingly important in meeting these demands.One of the key strengths of {Company Name} is its extensive experience in developing and implementing advanced packaging technologies. With a dedicated team of engineers and technicians, {Company Name} has the expertise to take full advantage of COB wire bonding and maximize its benefits for clients. By utilizing state-of-the-art equipment and cutting-edge processes, {Company Name} can offer superior COB wire bonding solutions that meet the highest standards of quality and reliability.The application of COB wire bonding extends across a wide range of industries, including consumer electronics, automotive, aerospace, and medical devices. As these industries continue to demand more compact and efficient electronic components, the importance of COB wire bonding will only continue to grow. By partnering with {Company Name}, semiconductor manufacturers can access the expertise and capabilities needed to stay ahead of the curve in this rapidly evolving market.In addition to its technical capabilities, {Company Name} is committed to providing exceptional customer service and support. The company works closely with its clients to understand their specific requirements and develop tailored solutions that address their unique needs. Whether it's optimizing the design of a COB wire bonding layout or ensuring the highest levels of quality control, {Company Name} is dedicated to delivering the best possible outcomes for its customers.As the semiconductor industry continues to push the boundaries of performance and miniaturization, innovative technologies like COB wire bonding will play a crucial role in driving progress. With its deep expertise and commitment to excellence, {Company Name} is well-equipped to lead the way in adopting and advancing COB wire bonding technology. By leveraging the benefits of COB wire bonding, semiconductor manufacturers can achieve greater efficiency, lower costs, and higher performance, ultimately gaining a competitive edge in the market.Moving forward, {Company Name} will continue to invest in research and development to further enhance its COB wire bonding capabilities. By staying at the forefront of technological advancements, {Company Name} aims to support its clients in meeting the ever-evolving demands of the semiconductor industry. With a strong focus on innovation and customer satisfaction, {Company Name} is poised to be a key player in shaping the future of semiconductor manufacturing through COB wire bonding technology.

Customized PCB Box Build Services for Your Electronics Needs

Pcb Box Build (name removed) is a leading provider of innovative and high-quality solutions for the electronics industry. With a focus on PCB assembly and box build services, the company has been at the forefront of technological advancements and has earned a reputation for excellence in the industry.The company's expertise in PCB assembly and box build services is unmatched, and they have a track record of delivering superior products to their customers. Their state-of-the-art manufacturing facilities and a team of highly skilled professionals have enabled them to consistently meet the evolving needs of the electronics industry.In a recent development, Pcb Box Build has announced the launch of a new range of box build services that are set to revolutionize the industry. The company is known for its commitment to innovation and has once again proven to be a pioneer in the field. The new box build services are designed to cater to the diverse needs of the electronics industry and offer a wide range of options for customers.The new range of box build services includes custom assembly, testing, and integration of electronic components. Pcb Box Build has leveraged its extensive experience and expertise to develop these services, with a focus on delivering cost-effective and efficient solutions that meet the highest standards of quality. The company is confident that these new services will provide an edge to their customers and help them stay ahead in the ever-changing electronics market.One of the key features of this new offering is the company's ability to handle complex assembly and integration processes. Pcb Box Build has invested in advanced technology and equipment to ensure that they have the capabilities to handle the most challenging projects. This includes the ability to work with a wide range of electronic components and ensure that they are seamlessly integrated into the final product.Furthermore, Pcb Box Build has also placed a strong emphasis on quality control and testing. The company is committed to ensuring that all products meet the highest standards of performance and reliability. Their rigorous testing and inspection processes are designed to identify and rectify any issues before the final product is delivered to the customer. This ensures that customers can have full confidence in the products they receive from Pcb Box Build.In addition to their technical capabilities, Pcb Box Build is also known for its customer-centric approach. The company takes pride in its ability to understand and respond to the unique needs of each customer. Their team of experts works closely with clients to develop tailored solutions that meet their specific requirements. This personalized approach has been a key factor in the company's success and has led to long-term partnerships with many leading companies in the electronics industry.The launch of the new range of box build services is a testament to Pcb Box Build's ongoing commitment to excellence and innovation. The company continues to push the boundaries of what is possible in the electronics industry and is dedicated to creating value for its customers. With a focus on quality, efficiency, and customer satisfaction, Pcb Box Build is well-positioned to continue its leadership in the industry for years to come.

Top Medical PCB Assembly Suppliers: A In-Depth Look

Medical PCB Assembly Suppliers and [Company Name]'s Expertise in Meeting the Demands of Medical Device IndustryIn today's fast-paced world, the demand for advanced medical devices and equipment is constantly on the rise. As a result, medical PCB assembly suppliers play a crucial role in the development and production of these devices. [Company Name] is a leading PCB assembly supplier that specializes in meeting the specific needs of the medical device industry, offering top-quality, reliable, and efficient solutions for the production of medical electronics.[Company Name] has a long-standing reputation for excellence and innovation in the field of PCB assembly. With a commitment to quality, precision, and customer satisfaction, the company has established itself as a trusted partner for medical device manufacturers. By leveraging cutting-edge technology and industry expertise, [Company Name] is able to provide customized PCB assembly solutions that meet the stringent requirements of the medical device industry.The medical device industry has unique and demanding specifications that require precision and reliability in PCB assembly. [Company Name] understands these requirements and has developed an extensive portfolio of services and capabilities to address these specific needs. From prototype development to full-scale production, the company offers a comprehensive range of PCB assembly services that are tailored to the stringent regulatory and quality standards of the medical device industry.The company's state-of-the-art manufacturing facilities are equipped with advanced machinery and equipment, allowing for the efficient production of high-quality PCB assemblies. [Company Name]'s team of skilled engineers and technicians are experienced in working with medical device manufacturers to develop and manufacture PCB assemblies that meet the highest standards of quality and performance.In addition to its manufacturing capabilities, [Company Name] also places a strong emphasis on quality control and testing. The company follows strict quality assurance protocols throughout the production process to ensure that every PCB assembly meets the specific requirements of the medical device industry. [Company Name] is also ISO 13485 certified, demonstrating its commitment to maintaining the highest levels of quality and safety in its products and services.As a leading medical PCB assembly supplier, [Company Name] is dedicated to staying at the forefront of technological advancements in the industry. The company invests in ongoing research and development to continuously enhance its capabilities and to meet the evolving demands of the medical device market. By staying ahead of industry trends and innovations, [Company Name] is able to offer its customers the most advanced and reliable PCB assembly solutions available.The company's dedication to innovation and excellence has positioned it as a preferred partner for medical device manufacturers seeking reliable and high-quality PCB assembly services. With a proven track record of delivering top-notch products and services, [Company Name] has built strong relationships with clients in the medical device industry, earning a reputation for outstanding customer satisfaction and reliability.In conclusion, [Company Name] is a leading medical PCB assembly supplier that excels in meeting the unique and demanding requirements of the medical device industry. With a focus on quality, precision, and innovation, the company is committed to providing top-quality, reliable, and efficient PCB assembly solutions for medical electronics. By continuing to invest in advanced technology, quality control, and research and development, [Company Name] is well-positioned to remain a trusted partner for medical device manufacturers seeking superior PCB assembly services.

High-Quality Wire Bonding Supplier for your Electronic Components

Al Wire Bonding Supplier, a leading provider of advanced wire bonding solutions, has announced the release of their latest product line designed to meet the increasing demand for high-quality wire bonding in the semiconductor industry.With over 20 years of experience in the industry, Al Wire Bonding Supplier has established itself as a trusted supplier of advanced wire bonding technology. The company prides itself on its ability to deliver innovative solutions that meet the ever-evolving needs of its customers.The latest product line from Al Wire Bonding Supplier includes a range of cutting-edge wire bonding equipment and materials that are designed to offer unmatched performance and reliability. These products have been developed in response to the growing demand for more advanced wire bonding solutions, particularly in applications where precision and reliability are critical.One of the flagship products in the new line is the Advanced Wire Bonder, a state-of-the-art machine that offers advanced features such as ultra-high-speed bonding, enhanced process control, and greater flexibility in wire bonding applications. This machine is designed to meet the needs of semiconductor manufacturers who require high-speed, high-precision bonding for their advanced semiconductor devices.In addition to the Advanced Wire Bonder, Al Wire Bonding Supplier is also introducing a range of advanced wire bonding materials, including high-performance wire and bonding tools. These materials are specifically designed to work seamlessly with the new Advanced Wire Bonder, ensuring optimal performance and reliability in wire bonding applications."We are thrilled to introduce our latest product line, which represents a significant leap forward in wire bonding technology," said the spokesperson for Al Wire Bonding Supplier. "With the increasing demand for high-speed, high-precision wire bonding in the semiconductor industry, our new products are designed to help our customers stay ahead of the curve and deliver cutting-edge semiconductor devices with unmatched performance and reliability."In addition to the new product line, Al Wire Bonding Supplier continues to offer a range of support and services to its customers, including training, technical support, and consulting services. This comprehensive approach to customer support is a key differentiator for Al Wire Bonding Supplier, as it ensures that customers receive the assistance they need to maximize the performance and reliability of their wire bonding equipment and materials.As an established leader in the wire bonding industry, Al Wire Bonding Supplier is committed to driving innovation and delivering high-quality solutions that meet the evolving needs of its customers. With the release of its latest product line, the company is well-positioned to continue its legacy of excellence in the semiconductor industry and provide its customers with the advanced wire bonding solutions they require to succeed in a competitive market.In conclusion, Al Wire Bonding Supplier's latest product line represents a significant advancement in wire bonding technology, offering advanced solutions that are designed to meet the increasing demand for high-speed, high-precision wire bonding in the semiconductor industry. With its extensive experience and commitment to innovation, Al Wire Bonding Supplier continues to be a trusted partner for semiconductor manufacturers seeking reliable and high-performance wire bonding solutions.

Important Features to Consider in a Medical Device Motherboard

Medical Device Motherboard, in collaboration with industry leader in medical technology, {} has announced the launch of a breakthrough medical device motherboard that promises to revolutionize the healthcare industry. The new motherboard, which is the result of extensive research and development, is designed to provide unparalleled performance and reliability for a wide range of medical devices and equipment.The medical device motherboard is a critical component in medical devices such as patient monitoring systems, diagnostic equipment, and imaging devices. It serves as the central hub for processing and communicating data, and its performance and reliability are crucial for the accurate and timely delivery of healthcare services.The new medical device motherboard from {} and {}, offers several key improvements over existing solutions. It is built on the latest technology, utilizing state-of-the-art components and advanced manufacturing processes to ensure optimal performance and durability. This means that medical devices equipped with this motherboard will operate more efficiently and reliably, leading to better patient care and outcomes.The motherboard also incorporates advanced security features to protect sensitive patient data and ensure compliance with healthcare regulations. This is crucial in today’s increasingly connected healthcare environment, where cybersecurity threats pose a significant risk to patient safety and data privacy.Furthermore, the new medical device motherboard is designed to be highly customizable, allowing medical device manufacturers to tailor it to their specific requirements. This flexibility enables the development of innovative and specialized medical devices that can address the unique needs of healthcare providers and patients.In addition to its technical capabilities, the medical device motherboard also benefits from the extensive expertise and support of {}. As a leading provider of medical technology solutions, {} has a proven track record of delivering innovative and reliable products to the healthcare industry. Its deep understanding of the unique challenges and requirements of the healthcare sector makes it an ideal partner for the development and commercialization of the new medical device motherboard.The collaboration between {} and {} underscores the commitment of both companies to advancing healthcare technology and improving patient care. By combining their respective strengths and resources, they have been able to create a cutting-edge medical device motherboard that sets a new standard for performance, reliability, and security in medical devices.“We are thrilled to introduce this game-changing medical device motherboard in partnership with {}. This new technology represents a significant advancement in the field of medical devices, and we believe it will have a transformative impact on healthcare delivery,” said a spokesperson from {}.The launch of the new medical device motherboard comes at a time when the healthcare industry is undergoing rapid transformation, driven by technological advancements and evolving patient needs. With the increasing demand for connected and data-driven healthcare solutions, the availability of high-performance and secure medical device components is more important than ever.The new medical device motherboard from {} and {} is poised to address these evolving needs, offering a reliable and adaptable platform for the next generation of medical devices. Its availability is expected to catalyze the development of innovative healthcare solutions that can enhance patient care and support the efforts of healthcare providers.In conclusion, the launch of the new medical device motherboard from {} and {} represents a significant milestone in the advancement of medical technology. With its superior performance, reliability, and security features, this motherboard is set to positively impact the healthcare industry and contribute to improved patient outcomes. As healthcare technology continues to evolve, collaborations like this will play a crucial role in driving innovation and shaping the future of healthcare delivery.

Pioneering PCB Chip-On-Board Factory Streamlines Electronics Manufacturing Process

Title: PCB Chip-On-Board Factory Pioneers Advanced Manufacturing TechniquesIntroduction:In the world of electronics manufacturing, PCB (Printed Circuit Board) production is a crucial component that enables the smooth functioning of various electronic devices. One leading player in the field, a cutting-edge and innovative PCB Chip-On-Board factory, is revolutionizing the industry by combining advanced manufacturing techniques with top-notch expertise. With a commitment to quality and excellence, this factory has gained a stellar reputation for producing high-performance PCBs used in diverse industries. Let's delve into the company's profile and explore their approach to achieving manufacturing excellence.Company Profile:The PCB Chip-On-Board factory's core foundations are built upon years of experience and expertise in PCB manufacturing. Founded by a team of industry veterans, the factory has evolved into a top player known for its comprehensive product range, advanced technology, and exceptional customer service. With a state-of-the-art production facility equipped with cutting-edge machinery, the factory has achieved unmatched operational efficiency while ensuring compliance with international quality standards.Advanced Manufacturing Techniques:The PCB Chip-On-Board factory prides itself on its commitment to embracing the latest manufacturing techniques to meet the ever-evolving demands of the electronics industry. Utilizing advanced machinery and processes, the factory employs a combination of automation, machine learning, and artificial intelligence to streamline operations and minimize errors.1. Precision Placement Technology: The factory employs high-precision placement machines that can handle miniaturized components with utmost accuracy. This technology allows for the creation of densely packed PCBs, enabling circuitry designs that are both space-efficient and high-performing.2. Automated Optical Inspection (AOI): To ensure the highest quality standards, the factory employs AOI systems that use sophisticated cameras and intelligent algorithms to detect any defects or abnormalities during the manufacturing process. This advanced inspection technique guarantees that only flawless PCBs make their way to the customers.3. Surface Mount Technology (SMT): The factory excels in producing PCBs using surface mount technology, which involves mounting components directly onto the PCB's surface, eliminating the need for separate wiring. This technique enables higher component density, better electrical performance, and reduced assembly costs.4. Environmental Sustainability: The factory places immense emphasis on environmental sustainability by implementing eco-friendly manufacturing practices. They employ lead-free soldering techniques, utilize energy-efficient equipment, and promote recycling and responsible waste disposal methodologies. By reducing their carbon footprint, the factory demonstrates its commitment to preserving the environment.Customer-focused Approach:The PCB Chip-On-Board factory is renowned for its strong customer-centric approach. The highly skilled team consistently works closely with clients to understand their specific requirements and provide tailored solutions. Whether for industries such as automotive, consumer electronics, or telecommunications, the factory's engineers and technicians offer expertise and support throughout the product development process.Research and Development:Being at the forefront of technological advancements, the factory invests extensively in research and development to continually improve its products and processes. The team collaborates closely with clients, academia, and industry experts to explore emerging trends in design, materials, and testing methodologies. Through this commitment to innovation, the factory ensures it stays ahead in a competitive market.Conclusion:The PCB Chip-On-Board factory sets a benchmark in the electronics manufacturing industry by seamlessly integrating cutting-edge technologies with extensive expertise. Its commitment to advanced manufacturing techniques, environmental sustainability, and customer-focused approach has earned the factory a reputable standing in the market. With an unwavering dedication to quality and continual improvement, the factory is primed to remain a leader in producing high-performance PCBs for an array of industries worldwide.