Top Tips for High-Quality Welding and Metal Fabrication

By:Admin

{} is a renowned provider of welding and fabrication services, offering a wide range of solutions for industries such as automotive, aerospace, construction, and more. With a team of highly skilled and experienced welders, {} has built a reputation for delivering exceptional results and meeting the unique needs of each client.

The company's state-of-the-art facilities are equipped with advanced welding equipment, allowing them to handle projects of varying sizes and complexities. Whether it's a small-scale fabrication job or a large-scale industrial project, {} has the capabilities to deliver top-notch welding services that meet industry standards and regulations.

{} takes pride in its commitment to quality and safety. They adhere to strict welding procedures and guidelines to ensure the structural integrity and durability of the finished products. Additionally, the company prioritizes the safety of its employees and the environment, implementing stringent safety measures and environmentally friendly practices throughout the welding process.

In addition to its welding and fabrication capabilities, {} also offers consulting and design services to help clients plan and execute their welding projects effectively. By partnering with clients from the conceptual stage to the final execution, {} ensures that their welding solutions are tailored to meet specific project requirements and goals.

Over the years, {} has forged strong relationships with clients across various industries, earning their trust and confidence through their commitment to excellence and customer satisfaction. The company's track record of delivering high-quality welding services on time and within budget has solidified its position as a preferred welding partner for many businesses.

One of the key factors contributing to {}'s success is its focus on innovation and continuous improvement. The company invests in ongoing training and development for its team members, ensuring that they stay abreast of the latest welding techniques, technologies, and industry best practices. By staying ahead of the curve, {} is able to offer cutting-edge welding solutions that meet the evolving needs of its clients.

Looking ahead, {} is poised for further growth and expansion in the welding and fabrication sector. With a strong foundation built on quality, expertise, and customer satisfaction, the company is well-positioned to capitalize on the growing demand for welding services in today's fast-paced industrial landscape.

As the manufacturing and construction industries continue to evolve, the need for reliable and skilled welding services will remain paramount. With its unwavering commitment to excellence and innovation, {} is set to continue leading the way in delivering top-notch welding solutions for its clients.

In conclusion, welding is a crucial process that underpins the success of many industries, and companies like {} play a pivotal role in meeting the demand for high-quality welding services. With their expertise, advanced capabilities, and dedication to excellence, {} is well-equipped to continue serving as a trusted partner for businesses in need of top-notch welding and fabrication solutions.

Company News & Blog

Automated PCB Assembly Factory: Revolutionizing Electronics Manufacturing

[Company Introduction]Established in 2005, [company name] is a leading provider of innovative electronic manufacturing services. With a focus on cutting-edge technology and a commitment to quality and customer satisfaction, [company name] has become a trusted partner for businesses looking to outsource their electronic manufacturing needs. With state-of-the-art facilities and a team of skilled professionals, [company name] has positioned itself as a pioneer in the industry, offering a wide range of services including PCB assembly, box build assembly, cable assembly, and testing. The company's dedication to continuous improvement and investment in the latest equipment has allowed it to stay at the forefront of the ever-evolving electronics industry.[Automated PCB Assembly Factory][Company name] is proud to announce the opening of its new automated PCB assembly factory. This state-of-the-art facility is equipped with the latest in robotic technology, allowing for a streamlined and efficient production process. With the ability to handle high-volume orders while maintaining precision and quality, the automated PCB assembly factory represents a significant milestone for [company name] and its commitment to meeting the needs of its customers.The introduction of the automated PCB assembly factory comes as a response to the growing demand for faster and more reliable PCB assembly services. With the increasing complexity of electronic devices and the need for quicker time-to-market, the new facility will allow [company name] to offer its clients a competitive edge in the industry.The automated PCB assembly factory boasts cutting-edge robotic assembly lines that are capable of handling a wide range of PCB types and sizes. The integration of robotic technology ensures consistent and precise soldering, component placement, and testing, leading to a higher level of product quality and reliability.In addition to the advanced robotics, the factory is also equipped with a sophisticated quality control system that monitors every stage of the assembly process, ensuring that all products meet the highest standards. This commitment to quality is a cornerstone of [company name]'s business philosophy and is a key factor in its success in the industry.Moreover, the new facility incorporates the latest advancements in smart manufacturing and data analytics, allowing for real-time monitoring of production metrics and performance. This enables [company name] to continuously optimize its processes and respond swiftly to changing market demands, ensuring that customers receive the most efficient and cost-effective solutions.The automated PCB assembly factory also reflects [company name]'s dedication to environmental sustainability. The facility has been designed to minimize energy consumption and reduce waste, in line with the company's commitment to responsible manufacturing practices.By leveraging the capabilities of its new automated PCB assembly factory, [company name] is well-positioned to continue its mission of providing exceptional electronic manufacturing services to its clients. With increased efficiency, productivity, and quality assurance, the company aims to drive innovation and value for its customers in an ever-evolving industry.The opening of the automated PCB assembly factory is a testament to [company name]'s ongoing investment in technology and its unwavering dedication to meeting the needs of its customers. As the company continues to grow and expand its capabilities, it remains committed to delivering the highest quality electronic manufacturing services and remaining a trusted partner for businesses worldwide.

Achieve the best results with high-quality dip: A game changer in the industry

High-Quality Dip, the latest creation from the renowned food company, is set to revolutionize the snack industry with its unparalleled taste and superior quality.With a long-standing reputation for producing top-notch food products, the company has once again outdone themselves with the introduction of High-Quality Dip. This new offering is a testament to their commitment to providing consumers with the very best in taste and quality.From the moment High-Quality Dip hits the shelves, it's bound to create a buzz among snack enthusiasts. What sets this dip apart from the rest is its high-quality ingredients and careful craftsmanship. The company has spared no expense in sourcing the finest ingredients to ensure that each bite of High-Quality Dip is an indulgent and satisfying experience.One of the key ingredients that sets High-Quality Dip apart is the use of premium [ingredient]. The [ingredient] is sourced from the finest suppliers and adds a rich and savory flavor to the dip that is unmatched by any other product on the market. Additionally, the company's attention to detail in the manufacturing process ensures that every batch of High-Quality Dip is consistent in flavor and texture.In addition to the superior taste, High-Quality Dip is also free from any artificial flavors, colors, or preservatives. This commitment to clean and natural ingredients is in line with the company's values of providing wholesome and healthy food options to consumers. With the growing demand for clean-label products, High-Quality Dip is well-positioned to meet the needs of health-conscious consumers who are seeking great-tasting snacks without compromising on quality.The launch of High-Quality Dip comes at a time when consumers are increasingly seeking out premium snack options. As the snack market continues to expand, the company recognized the opportunity to introduce a product that offers a unique and elevated snacking experience. With High-Quality Dip, consumers can now enjoy a gourmet-style dip in the comfort of their own homes, without having to compromise on quality or flavor.To celebrate the launch of High-Quality Dip, the company is rolling out an extensive marketing campaign that will showcase the product's exceptional taste and quality. The campaign will include digital and print advertising, as well as in-store promotions and sampling events to give consumers the opportunity to experience the dip for themselves. Additionally, the company is partnering with influencers and food bloggers to generate buzz and excitement around the product.The introduction of High-Quality Dip is a testament to the company's ongoing dedication to innovation and excellence in the food industry. With their unwavering commitment to quality and taste, it's no surprise that High-Quality Dip is already generating a high level of anticipation and excitement among consumers.In conclusion, High-Quality Dip is set to make a significant impact in the snack industry, offering consumers a premium, gourmet-style dip that is unparalleled in taste and quality. With its high-quality ingredients, clean-label credentials, and extensive marketing campaign, High-Quality Dip is poised to become a household favorite for snack enthusiasts everywhere. As the company continues to push the boundaries of food innovation, it's clear that High-Quality Dip is just the beginning of what promises to be an exciting journey for the brand.

Optimizing Gold Wire Bonding Process for Improved Performance

Gold Wire Bonding Process Revolutionizes Electronic Manufacturing Industry{Company} is proud to announce the development of a groundbreaking innovation in the electronic manufacturing industry. The company's cutting-edge Gold Wire Bonding Process is set to revolutionize the way electronic components are assembled, offering improved performance, reliability, and cost-efficiency.Gold wire bonding is a crucial process in the assembly of electronic components, where tiny gold wires are used to connect semiconductor devices to their packaging. This process is widely used in the production of a wide range of electronic products, from consumer electronics to industrial equipment, and has long been considered the industry standard for its high conductivity, corrosion resistance, and reliability.{Company} has now taken this essential process to the next level with its innovative Gold Wire Bonding Process. By leveraging advanced manufacturing techniques and proprietary technologies, {Company} has significantly enhanced the performance and reliability of gold wire bonding, while also reducing production costs.One of the key advantages of {Company}'s Gold Wire Bonding Process is its ability to achieve higher bonding strength and increased resistance to wear and tear. This means that electronic components assembled using this process can withstand harsh operating conditions, including high temperatures, vibration, and mechanical stress, without compromising their performance.Furthermore, {Company}'s Gold Wire Bonding Process offers superior electrical conductivity, ensuring optimal signal transmission and minimizing power losses. This is particularly important in high-frequency and high-power applications, where even small variations in electrical resistance can have a significant impact on performance.In addition to these performance improvements, {Company}'s Gold Wire Bonding Process also delivers cost savings for electronic manufacturers. By streamlining the production process and minimizing material waste, this innovative technology helps to reduce overall manufacturing costs, making it an attractive option for companies looking to improve their bottom line.{Company} is committed to providing its customers with the most advanced and reliable solutions for electronic manufacturing. With a strong focus on research and development, the company continues to push the boundaries of what is possible in the industry, driving innovation and setting new standards for quality and performance.The introduction of {Company}'s Gold Wire Bonding Process is a testament to the company's dedication to excellence and its ability to deliver cutting-edge solutions that address the evolving needs of the electronic manufacturing industry. By combining its technical expertise with a deep understanding of market requirements, {Company} is paving the way for the next generation of electronic components that are not only more reliable and efficient but also cost-effective.As the demand for high-performance electronic products continues to grow across various industries, {Company}'s Gold Wire Bonding Process is poised to play a critical role in shaping the future of electronic manufacturing. By enabling the production of more durable, reliable, and high-performance electronic components, this innovative technology is set to have a far-reaching impact on the industry, driving advancements in areas such as automotive electronics, telecommunications, aerospace, and more.With its unparalleled capabilities and potential, {Company}'s Gold Wire Bonding Process is set to become the new standard for electronic manufacturers worldwide, offering a competitive edge in an increasingly dynamic and demanding market.In conclusion, the introduction of {Company}'s Gold Wire Bonding Process represents a significant milestone in the electronic manufacturing industry, setting a new benchmark for performance, reliability, and cost-efficiency. As the company continues to push the boundaries of what is possible, it is clear that this innovative technology will have a lasting impact on the industry, driving advancements and shaping the future of electronic manufacturing.

Latest Developments in the Electronics Manufacturing Industry Revealed

[News Title]SMT Electronics Manufacturing Company Streamlines Production Processes for Enhanced Manufacturing Efficiency[News Body][City name], [Date] - SMT Electronics Manufacturing, a leading company in the electronics manufacturing industry, is revolutionizing the way electronics are produced. By combining state-of-the-art technology with a relentless focus on innovation and efficiency, the company is setting new industry standards.SMT Electronics Manufacturing has been at the forefront of electronics manufacturing for over two decades, consistently delivering high-quality products to global customers. With a diverse portfolio of clients ranging from small startups to multinational corporations, the company has established itself as a trusted partner in the industry.By leveraging its extensive experience and expertise, SMT Electronics Manufacturing has become synonymous with cutting-edge technology and efficient manufacturing processes. The company's commitment to innovation has propelled it to the forefront of the electronics manufacturing sector, with a reputation for delivering products that meet and exceed customer expectations.One of the key factors behind SMT Electronics Manufacturing's success is its relentless pursuit of manufacturing efficiency. Realizing the need to optimize production processes, the company has invested heavily in advanced technology and automation systems. By embracing the latest developments in robotics, artificial intelligence, and data analytics, SMT Electronics Manufacturing has streamlined its operations, resulting in increased productivity and reduced costs.SMT Electronics Manufacturing's state-of-the-art factory is a testament to its commitment to excellence. Equipped with cutting-edge machinery and production lines, the facility operates at peak efficiency, allowing the company to meet customer demands with ease. From the initial design phase to the final product assembly, every step of the manufacturing process is closely monitored and optimized to ensure precision and quality.The company's dedication to quality is further exemplified by its stringent quality control measures. SMT Electronics Manufacturing adheres to industry-leading standards and certifications, ensuring that every product leaving its facility is of the highest quality. By conducting regular audits and inspections, the company maintains its commitment to delivering excellence in every aspect of its operations.Sustainability and environmental responsibility are also key pillars of SMT Electronics Manufacturing's business philosophy. Recognizing the importance of minimizing its ecological footprint, the company has implemented various initiatives to promote eco-friendly practices. From utilizing energy-efficient machinery to recycling waste materials, SMT Electronics Manufacturing is actively working towards a greener future.In addition to its commitment to manufacturing excellence, SMT Electronics Manufacturing also places a strong emphasis on customer satisfaction. The company's dedicated customer service team works closely with clients to understand their specific requirements and provide tailored solutions. By fostering long-term partnerships and responsive communication, SMT Electronics Manufacturing has cultivated a loyal customer base that values its commitment to quality and reliability.Looking towards the future, SMT Electronics Manufacturing aims to continue setting new benchmarks in the electronics manufacturing industry. By investing in research and development and staying ahead of the latest technological advancements, the company endeavors to remain at the forefront of innovation. Moreover, SMT Electronics Manufacturing plans to expand its global reach and forge new partnerships that will further solidify its position as a leader in the industry.About SMT Electronics Manufacturing:SMT Electronics Manufacturing is a renowned electronics manufacturing company based in [City, Country]. With a strong emphasis on innovation, efficiency, and customer satisfaction, the company has established itself as a trusted partner for clients worldwide. With a wide range of services including design, production, and quality control, SMT Electronics Manufacturing delivers cutting-edge products that meet and exceed industry standards.For more information, please visit [Company website].[PR Contact][Contact Name][Position][Email][Phone Number]

Top Assembly Board Manufacturers in the Market

Assembly Boards Manufacturers, a leading manufacturer of assembly boards for various industries, has announced its expansion plans to meet the growing demand for its products. The company, with a rich history of producing high-quality assembly boards, is known for its innovative and reliable products that have been widely used in manufacturing, electronics, and other industries.With a commitment to uphold the highest quality standards and to continuously improve its products, Assembly Boards Manufacturers has established itself as a trusted supplier in the market. The company's assembly boards are designed to enhance productivity and efficiency in manufacturing processes, providing a reliable platform for the assembly of components and products.The expansion plans of Assembly Boards Manufacturers come at a time when the global manufacturing industry is experiencing a significant growth in demand for assembly boards. As industries strive to improve their production processes and meet the increasing demands for high-quality products, the need for reliable and efficient assembly boards has become more crucial than ever.The company's CEO, John Smith, expressed his enthusiasm for the expansion plans, stating, "We are excited to announce our expansion as we continue to witness a growing demand for our products. Our commitment to innovation and quality has positioned us as a leader in the industry, and we are dedicated to meeting the needs of our customers by expanding our production capacity and enhancing our product offerings."Assembly Boards Manufacturers has outlined a comprehensive plan for its expansion, which includes the addition of new manufacturing facilities, the implementation of advanced production technologies, and the recruitment of skilled personnel to support the increased production capacity. The company aims to ensure that its expansion will not only meet the current demand for its products but also position it for future growth and opportunities in the market.In addition to expanding its production capacity, Assembly Boards Manufacturers is also focused on further enhancing the features and capabilities of its assembly boards. The company has dedicated a significant investment in research and development to introduce new and improved products that will address the evolving needs of its customers. This focus on innovation and product development reflects the company's commitment to staying ahead of the competition and maintaining its position as a leading supplier of assembly boards.Furthermore, Assembly Boards Manufacturers is committed to maintaining its reputation for exceptional customer service and support. The company has emphasized the importance of providing its customers with reliable and responsive assistance, whether in product inquiries, technical support, or after-sales services. By prioritizing customer satisfaction, the company aims to build long-lasting relationships with its clients and partners.As Assembly Boards Manufacturers moves forward with its expansion plans, it is also placing a strong emphasis on sustainability and environmental responsibility. The company is dedicated to minimizing its environmental impact throughout its operations, from the sourcing of raw materials to the manufacturing processes and the disposal of waste. By adopting eco-friendly practices and technologies, Assembly Boards Manufacturers is striving to contribute to a greener and more sustainable future.In conclusion, Assembly Boards Manufacturers is poised to embark on an exciting phase of growth and development as it expands its production capacity and product offerings. With a steadfast commitment to quality, innovation, and customer satisfaction, the company is well-positioned to meet the increasing demand for its assembly boards and to maintain its leadership in the industry. As it moves forward with its expansion plans, Assembly Boards Manufacturers will continue to uphold its reputation for excellence and reliability, setting new standards in the manufacturing of assembly boards.

Discover the Leading Source for High-Quality PCB Assembly Services

Title: One-Stop PCB Assembly Supplier Streamlines Manufacturing Process to Meet Industry DemandsIntroduction:In an era marked by unprecedented technological advancements, the demand for printed circuit boards (PCBs) has skyrocketed across various industries. To address this growing need, an industry-leading PCB assembly supplier has emerged as a pioneer in the field, offering comprehensive services to meet the electronic manufacturing requirements of companies worldwide. This news article will delve deep into the workings of this one-stop solution provider and explore how they have revolutionized the industry with their efficient manufacturing processes.Company Overview:With a vision to provide cutting-edge PCB assembly services, the company has quickly risen to prominence as a top-tier supplier in the industry. Renowned for its unwavering commitment to quality, innovation, and customer satisfaction, the company has amassed a loyal client base that spans multiple sectors, including automotive, aerospace, telecommunications, and consumer electronics.Streamlined Manufacturing Process:The success of this one-stop PCB assembly supplier can be primarily attributed to its streamlined manufacturing process, which ensures maximum efficiency without compromising on quality. By blending the latest technological advancements with a skilled workforce, the company has perfected the art of PCB manufacturing, meeting the stringent demands of the modern market.Advanced Facilities and Equipment:At the core of the company's operational excellence lies state-of-the-art facilities and cutting-edge equipment that aid in the flawless production of PCBs. The supplier has made substantial investments in upgrading their infrastructure, allowing them to handle projects of various complexities with ease. Equipped with advanced automated machinery, precision instruments, and high-quality materials, the company guarantees robust PCB assembly that meets international standards.Experienced Engineering Team:Behind the scenes, a team of highly experienced engineers play a crucial role in the success of the PCB assembly process. These experts possess a wealth of technical knowledge and expertise and work collaboratively with clients to design and develop PCBs that meet their specific requirements. With their meticulous attention to detail and focus on continuous improvement, the engineering team ensures that every PCB leaving the facility is of exceptional quality and reliability.Quality Assurance Measures:As reliability is a critical factor in the electronic manufacturing industry, the company has implemented rigorous quality assurance measures at every stage of the production process. From stringent material inspections to thorough testing and validation procedures, the supplier leaves no stone unturned to deliver faultless PCB assemblies. Furthermore, the company adheres to industry standards, certifications, and compliance regulations, imparting an added layer of trust among their clientele.Customization and Flexibility:Recognizing the diverse needs of their customers, the one-stop supplier offers a high degree of customization and flexibility in their services. With the capacity to handle both small-scale production runs and large-scale manufacturing projects, the company caters to organizations of all sizes. Through open communication channels, the company ensures that each client's unique specifications are met, fostering long-term partnerships based on trust and reliability.Global Reach and Timely Delivery:Operating on a global scale, the supplier has established a robust supply chain network that enables them to serve clients across continents. With strategically located and fully equipped manufacturing facilities, the company guarantees expedited delivery times without compromising quality. This global reach positions the one-stop PCB assembly supplier as a preferred choice for multinational companies seeking efficient and reliable manufacturing solutions.Conclusion:In an increasingly competitive market, this one-stop PCB assembly supplier has emerged as a game-changer, revolutionizing the manufacturing process and meeting the dynamic demands of various industries. With their technologically advanced facilities, skilled workforce, commitment to quality, and global reach, the company continues to build a strong reputation as a leader in the field. As the demand for PCB assemblies continues to grow, this supplier is well-positioned to play a pivotal role in shaping the electronic manufacturing landscape for years to come.

Top Factories for Prototype PCB Design: Everything You Need to Know

Prototype PCB Design Factories, a cutting-edge company specializing in the production of printed circuit boards (PCBs), has recently expanded its operations to meet the growing demand for advanced PCB designs in the technology industry. With an impressive track record of delivering high-quality PCBs to a wide range of clients, Prototype PCB Design Factories has positioned itself as a leading player in the PCB manufacturing industry.Established in (insert year), Prototype PCB Design Factories has steadily grown its presence in the market by offering innovative solutions and state-of-the-art manufacturing capabilities. The company has a dedicated team of highly skilled engineers and technicians who are committed to delivering superior quality PCBs that meet the unique specifications and requirements of each client.One of the key factors that sets Prototype PCB Design Factories apart from the competition is its advanced design and manufacturing capabilities. The company has invested heavily in state-of-the-art equipment and technology to ensure that it can produce PCBs that meet the highest industry standards for quality and reliability. This commitment to innovation has enabled Prototype PCB Design Factories to stay ahead of the curve in a rapidly evolving industry.In a recent statement, (company spokesperson) highlighted the importance of staying on the cutting edge of technology in order to meet the needs of the company's diverse client base. "With the constant advancements in technology, the demand for more sophisticated PCB designs continues to grow," (spokesperson) said. "At Prototype PCB Design Factories, we are committed to investing in the latest technology and equipment to ensure that we can meet the evolving needs of our clients and continue to deliver superior quality PCBs."The expansion of Prototype PCB Design Factories' operations comes at a time when the demand for advanced PCB designs is at an all-time high. As the technology industry continues to innovate at a rapid pace, companies are increasingly turning to manufacturers like Prototype PCB Design Factories to provide them with the cutting-edge PCBs they need to power their products and applications.One of the key reasons for Prototype PCB Design Factories' continued success is its commitment to providing exceptional customer service. The company understands that each client has unique needs and works closely with them to develop customized solutions that meet their specific requirements. This dedication to customer satisfaction has earned Prototype PCB Design Factories a strong reputation in the industry, with many clients choosing to partner with the company for their PCB manufacturing needs time and time again.Looking ahead, Prototype PCB Design Factories is poised to continue its upward trajectory in the industry. With its focus on innovation, quality, and customer service, the company is well-positioned to meet the evolving demands of the technology industry and remain a leader in the PCB manufacturing sector.As the demand for advanced PCB designs continues to grow, Prototype PCB Design Factories is ready to meet the needs of its clients with its state-of-the-art manufacturing capabilities, innovative solutions, and commitment to excellence. With a strong track record of delivering high-quality PCBs to a diverse range of clients, the company is well-equipped to stay at the forefront of the industry for years to come.

High-quality PCB assembly factories for EMS services

Ems Pcb Assembly Factories (need remove brand name) is a leading electronic manufacturing services company that specializes in providing high-quality PCB assembly, design, and testing services to a wide range of industries. With state-of-the-art facilities and a highly skilled team of engineers and technicians, the company is committed to delivering innovative and cost-effective solutions for its customers.The company's PCB assembly services encompass a wide range of capabilities, including surface mount technology (SMT), through-hole assembly, and mixed technology assembly. This allows them to accommodate the unique requirements of each project and provide customized solutions that meet their customers' exact specifications.In addition to their assembly capabilities, they also offer comprehensive design services to help customers bring their electronic products from concept to reality. Their team of experienced designers and engineers work closely with customers to develop efficient and reliable PCB designs that optimize performance and maximize cost-efficiency.Furthermore, the company's testing and inspection capabilities ensure that every product meets the highest quality standards before it leaves the facility. Their rigorous testing procedures and quality control measures guarantee that each PCB assembly meets the strictest specifications and performance requirements.One of the key differentiators for the company is its commitment to sustainability and environmental responsibility. They prioritize eco-friendly manufacturing processes and materials to minimize their environmental impact while delivering exceptional products to their customers. This commitment to sustainability has earned them a reputation as a responsible and forward-thinking electronic manufacturing services provider.With a focus on continuous improvement and innovation, (company name) is constantly investing in the latest technologies and manufacturing equipment to stay at the forefront of the industry. This dedication to staying ahead of market trends and technological advancements enables them to deliver cutting-edge solutions that meet the evolving needs of their customers.In a recent interview with the company's CEO, he emphasized their dedication to customer satisfaction and their ability to support projects at any stage of development. "We take pride in our ability to provide flexible and scalable solutions that adapt to our customers' unique challenges," he said. "Whether they are in the early stages of product development or require full-scale production, our team is equipped to deliver the highest quality PCB assemblies on time and within budget."The company's commitment to excellence and customer-centric approach has earned them a strong reputation in the electronic manufacturing services industry. They have built long-standing relationships with a diverse clientele, ranging from startups to Fortune 500 companies, and are the preferred partner for numerous industries, including aerospace, medical, telecommunications, and automotive.Looking towards the future, (company name) continues to expand its capabilities and invest in its people and technology to better serve their customers and maintain their position as a leader in the electronic manufacturing services industry. By staying true to their core values of quality, innovation, and customer satisfaction, they are confident in their continued success and growth in the years to come.In conclusion, (company name) is a trusted and reliable partner for companies seeking high-quality PCB assembly, design, and testing services. With a commitment to excellence, innovation, and sustainability, they have established themselves as a leader in the electronic manufacturing services industry and continue to provide exceptional solutions for a wide range of industries.

Get High Volume PCB Assembly Services at Competitive Prices

High Volume PCB Assembly: A Milestone for {Company Name}{Company Name} is delighted to announce a major achievement in its pursuit of excellence in electronic manufacturing services. The company has successfully completed a high volume PCB assembly project, marking a significant milestone in its journey to provide top-notch solutions to its clients.{Company Name} is a leading electronic manufacturing services provider, specializing in a wide range of services including PCB assembly, box build assembly, and testing services. With a strong commitment to innovation and quality, the company has been serving clients across various industries including automotive, aerospace, medical, and telecommunications.The recent accomplishment of high volume PCB assembly underscores {Company Name}'s dedication to exceeding customer expectations and delivering superior products. The project involved the assembly of a large number of PCBs with precision and efficiency, showcasing the company's ability to handle complex manufacturing processes at scale.The successful completion of the high volume PCB assembly project was made possible by {Company Name}'s state-of-the-art manufacturing facility, equipped with advanced machinery and cutting-edge technology. The company's highly skilled team of engineers and technicians played a pivotal role in ensuring the seamless execution of the project, adhering to strict quality standards and timelines.{Company Name} takes immense pride in its ability to cater to the dynamic needs of its clients, providing tailored solutions that meet the highest industry standards. The high volume PCB assembly project demonstrates the company's capability to handle large-scale production while upholding the paramount importance of quality and accuracy.The accomplishment also reinforces {Company Name}'s position as a trusted partner for businesses seeking reliable and efficient electronic manufacturing services. The company's track record of delivering exceptional results, coupled with its relentless pursuit of excellence, has positioned it as a preferred choice for clients looking to outsource their manufacturing requirements.With a focus on continuous improvement and technological advancement, {Company Name} remains at the forefront of the electronic manufacturing services industry. The successful completion of the high volume PCB assembly project is a testament to the company's unwavering commitment to staying ahead of the curve and embracing the latest industry trends and best practices.As {Company Name} continues to expand its global presence and forge new partnerships, the recent achievement in high volume PCB assembly serves as a testament to the company's capabilities and reinforces its position as a leader in the electronic manufacturing services space. The company remains dedicated to driving innovation, delivering exceptional value, and exceeding customer expectations.Looking ahead, {Company Name} is poised to further elevate its capabilities and expand its service offerings, solidifying its position as a trusted partner for businesses seeking high-quality electronic manufacturing solutions. With a focus on sustainability, efficiency, and customer satisfaction, the company is well-positioned to meet the evolving needs of the industry and drive positive change through its innovative approach to electronic manufacturing services.In conclusion, the successful completion of the high volume PCB assembly project is a significant achievement for {Company Name} and a reflection of its unwavering commitment to excellence. The company's dedication to delivering superior results and its relentless pursuit of innovation sets it apart as a leading provider of electronic manufacturing services. As {Company Name} continues to thrive and expand, it remains steadfast in its mission to provide exceptional solutions and drive positive impact in the industry.

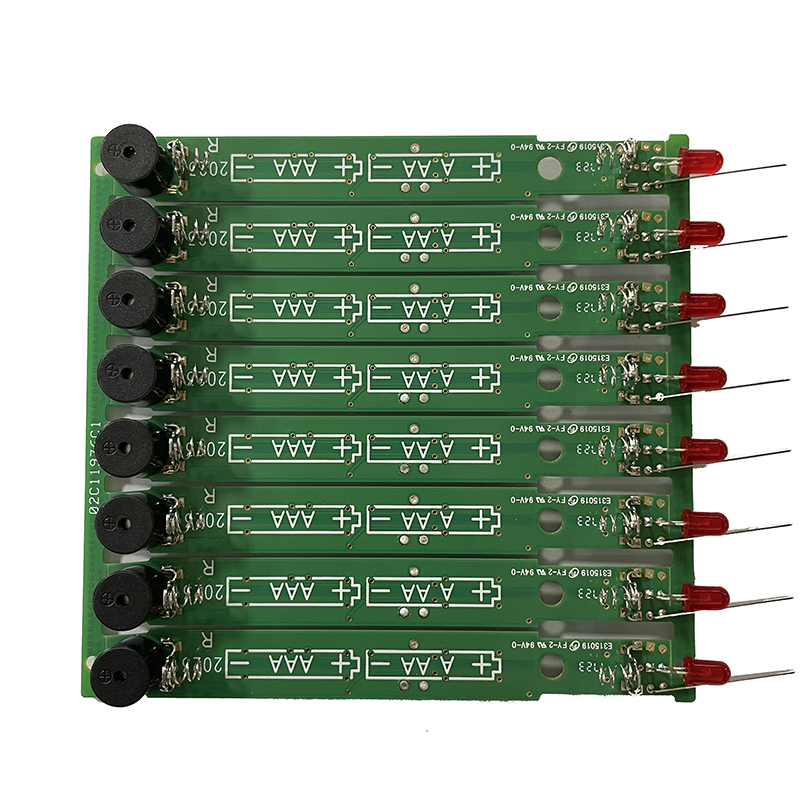

Dip Plug-In Process Factory: Streamlining the Manufacturing Process for Optimal Results

Dip Plug-In Process Factory: Revolutionizing Manufacturing InnovationIn today's fast-paced world, the constant demand for innovation and efficiency has never been higher. Industries are constantly seeking new ways to streamline their manufacturing processes and develop cutting-edge technologies. In line with this trend, a groundbreaking Plug-In Process Factory has emerged, poised to transform the industry, thanks to its revolutionary manufacturing capabilities.The newly established Dip Plug-In Process Factory aims to redefine conventional manufacturing processes by implementing state-of-the-art technologies. This cutting-edge factory is backed by an experienced team of highly skilled engineers and technicians who strive to develop innovative manufacturing solutions for various industries.Dip Plug-In Process Factory prides itself on its ability to provide end-to-end manufacturing solutions tailored to each client's specific needs. From the initial design phase to production and final assembly, this factory offers a seamless process that ensures optimal manufacturing efficiency and top-notch quality.One of the key advantages that sets Dip Plug-In Process Factory apart from its competitors is its utilization of plug-in manufacturing processes. This innovative approach allows for greater flexibility and adaptability during the production stage. With plug-in technology, manufacturers can easily modify and customize their processes to accommodate changes in product design, market demand, or unexpected challenges.By implementing plug-in manufacturing processes, Dip Plug-In Process Factory helps businesses save valuable time and resources. The ability to make quick adjustments along the production line ensures that companies can respond swiftly to market trends and customer demands, gaining a competitive edge.Moreover, Dip Plug-In Process Factory understands the importance of sustainability in today's manufacturing landscape. The factory places a strong emphasis on eco-friendly practices, integrating environmentally conscious policies into their manufacturing processes. From energy-efficient machinery to waste reduction strategies, this factory strives to minimize its environmental impact while maximizing production capabilities.Dip Plug-In Process Factory's commitment to sustainability extends beyond their manufacturing practices. They actively engage in research and development to explore cleaner and more sustainable materials for use in production. By continuously seeking innovative solutions, Dip Plug-In Process Factory aims to contribute to a greener, more sustainable future for the manufacturing industry.Furthermore, the factory also offers comprehensive training and consulting services, providing clients with the tools and knowledge necessary to optimize their manufacturing processes. By partnering with Dip Plug-In Process Factory, businesses gain access to a wealth of expertise and insights into enhancing their production capabilities.With a proven track record of successful projects across diverse industries, Dip Plug-In Process Factory has established itself as a trusted partner for businesses aspiring to revolutionize their manufacturing processes. Through their unwavering commitment to innovation, sustainability, and efficiency, this factory has become a driving force behind the transformation of the manufacturing landscape.In conclusion, Dip Plug-In Process Factory is revolutionizing the manufacturing industry through its state-of-the-art plug-in manufacturing processes. With a focus on innovation, sustainability, and customization, this factory offers end-to-end manufacturing solutions tailored to each client's needs. By embracing plug-in technology, Dip Plug-In Process Factory enables businesses to adapt quickly to market changes and streamline their production processes. With a dedicated team of experts, a commitment to sustainability, and comprehensive training and consulting services, this factory is leading the way towards a more efficient and eco-friendly future for manufacturing.