Customized PCB Box Build Services for Your Electronics Needs

By:Admin

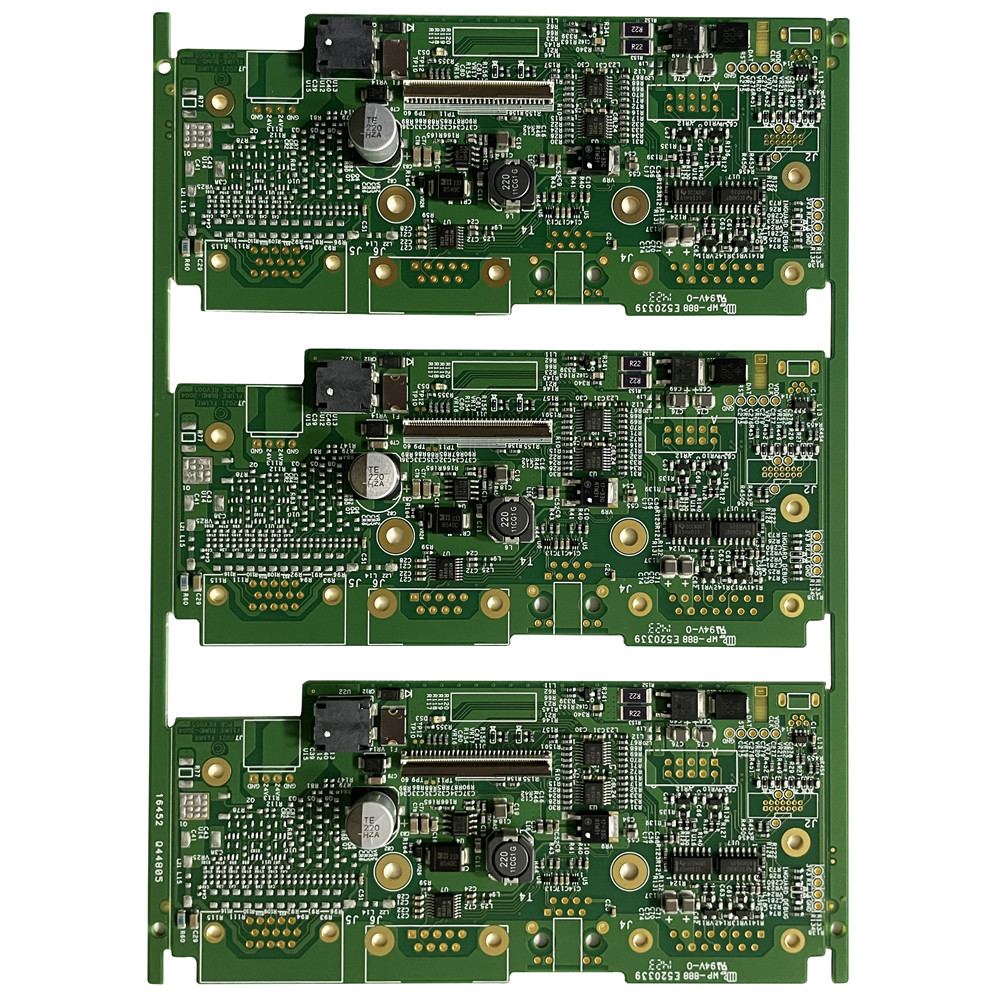

The company's expertise in PCB assembly and box build services is unmatched, and they have a track record of delivering superior products to their customers. Their state-of-the-art manufacturing facilities and a team of highly skilled professionals have enabled them to consistently meet the evolving needs of the electronics industry.

In a recent development, Pcb Box Build has announced the launch of a new range of box build services that are set to revolutionize the industry. The company is known for its commitment to innovation and has once again proven to be a pioneer in the field. The new box build services are designed to cater to the diverse needs of the electronics industry and offer a wide range of options for customers.

The new range of box build services includes custom assembly, testing, and integration of electronic components. Pcb Box Build has leveraged its extensive experience and expertise to develop these services, with a focus on delivering cost-effective and efficient solutions that meet the highest standards of quality. The company is confident that these new services will provide an edge to their customers and help them stay ahead in the ever-changing electronics market.

One of the key features of this new offering is the company's ability to handle complex assembly and integration processes. Pcb Box Build has invested in advanced technology and equipment to ensure that they have the capabilities to handle the most challenging projects. This includes the ability to work with a wide range of electronic components and ensure that they are seamlessly integrated into the final product.

Furthermore, Pcb Box Build has also placed a strong emphasis on quality control and testing. The company is committed to ensuring that all products meet the highest standards of performance and reliability. Their rigorous testing and inspection processes are designed to identify and rectify any issues before the final product is delivered to the customer. This ensures that customers can have full confidence in the products they receive from Pcb Box Build.

In addition to their technical capabilities, Pcb Box Build is also known for its customer-centric approach. The company takes pride in its ability to understand and respond to the unique needs of each customer. Their team of experts works closely with clients to develop tailored solutions that meet their specific requirements. This personalized approach has been a key factor in the company's success and has led to long-term partnerships with many leading companies in the electronics industry.

The launch of the new range of box build services is a testament to Pcb Box Build's ongoing commitment to excellence and innovation. The company continues to push the boundaries of what is possible in the electronics industry and is dedicated to creating value for its customers. With a focus on quality, efficiency, and customer satisfaction, Pcb Box Build is well-positioned to continue its leadership in the industry for years to come.

Company News & Blog

Discover the Advantages of High-Quality Wire Bonding for Au

Title: Revolutionizing Wire Bonding Technology: Unleashing High-Quality Au Wire BondingIntroduction (111 words):As technology continues to advance at an unprecedented pace, the need for cutting-edge wire bonding solutions is more significant than ever before. Today, we present an innovative breakthrough in the field of wire bonding that promises high-quality results and exceptional performance. In collaboration with a leading industry player, we are pleased to introduce a groundbreaking wire bonding technique that maximizes productivity and achieves unparalleled precision. This revolutionary technology, referred to as High-Quality Au Wire Bonding, holds the potential to disrupt existing norms and redefine industry standards. Read on to explore the extraordinary capabilities of this game-changing technology and its potential implications in various sectors.Section 1: The Deterioration of Conventional Wire Bonding (175 words):Conventional wire bonding techniques have long been the standard in the industry, helping to establish reliable electrical connections between integrated circuits (ICs) and the substrate. However, in recent years, the limitations of these traditional methods have become increasingly evident. Challenges associated with wire stability, wire-bond interconnects, and overall performance have prompted the need for a transformative solution.Section 2: Introducing High-Quality Au Wire Bonding (183 words):Responding to the shortcomings of conventional wire bonding, the collaboration between our company and a key industry partner has paved the way for High-Quality Au Wire Bonding. By incorporating cutting-edge materials and advanced manufacturing processes, this new technique offers a host of advantages over its predecessors.The utilization of gold wire, renowned for its superior conductivity and stability, ensures optimal electrical performance of the wire-bond interconnects. Furthermore, the refined manufacturing process lends itself to better control over wire looping, resulting in excellent wire-bond reliability.Section 3: Unleashing Unrivaled Performance and Durability (180 words):High-Quality Au Wire Bonding offers a range of impressive benefits, including enhanced electrical conductivity, superior mechanical strength, and improved long-term reliability. The utilization of gold wire eliminates concerns related to oxidation and corrosion, which are often encountered with alternative wire bonding materials. This ensures stable performance and durability, even under challenging environmental conditions.The precise control and consistency achieved during the manufacturing process also enable a reduction in defects and yield losses. Consequently, this groundbreaking technology provides manufacturers with significant cost savings and increased productivity.Section 4: Applications in Various Sectors (150 words):The adaptability and exceptional performance of High-Quality Au Wire Bonding provide immense opportunities for various sectors. Industries such as automotive, telecommunications, aerospace, and consumer electronics can benefit greatly from this cutting-edge wire bonding solution.New developments in electric vehicles (EVs) and autonomous driving technologies require highly reliable electrical connections, making High-Quality Au Wire Bonding an ideal choice. In the telecommunications sector, the need for high-speed data transfer necessitates robust wire bonding techniques, and this new technology excels in meeting these demands.Conclusion (101 words):High-Quality Au Wire Bonding represents a significant leap forward in the realm of wire bonding technology. Its unique advantages, including excellent electrical conductivity, enhanced mechanical strength, and increased durability, make it an invaluable tool for many industries. As we look towards the future, the potential implications and endless possibilities of this game-changing wire bonding technique are undeniably exciting. By embracing this revolutionary technology, manufacturers can achieve unparalleled precision, reliability, and productivity, ushering in a new era of wire bonding excellence.

High-Quality SMT Soldering Machine for Efficient Electronics Manufacturing

China's Leading Smt Soldering Machine Manufacturer Introduces New Revolutionary ModelChina is renowned for its advanced manufacturing capabilities, and its Smt Soldering Machine industry is no exception. One of the leading manufacturers in this field has recently introduced a new revolutionary model that is set to redefine the standard for Smt Soldering Machines worldwide.With a long-standing reputation for producing high-quality, reliable, and technologically advanced machinery, {Company Name} has become a trusted name in the Smt Soldering Machine industry. The company's commitment to innovation and excellence has earned it the trust and loyalty of customers around the globe.The new Smt Soldering Machine model, which was unveiled at a recent industry trade show in China, has already garnered significant attention due to its cutting-edge features and capabilities. The machine is designed to offer superior soldering performance, increased efficiency, and reduced downtime, making it an essential tool for electronics manufacturing companies seeking to optimize their production processes.One of the standout features of the new Smt Soldering Machine is its advanced soldering technology, which enables precise and consistent soldering results. This technology is a game-changer for electronics manufacturers, as it ensures the highest quality soldering for their products, ultimately leading to increased reliability and customer satisfaction.In addition to its advanced soldering technology, the new Smt Soldering Machine boasts a user-friendly interface that simplifies operation and maintenance. This intuitive interface makes it easy for operators to set up the machine, monitor the soldering process, and address any issues that may arise, thereby minimizing the risk of errors and maximizing productivity.Furthermore, the machine is equipped with state-of-the-art safety features, ensuring the well-being of operators and preventing accidents in the workplace. This focus on safety aligns with {Company Name}'s commitment to providing not only top-of-the-line machinery but also a secure working environment for its customers.{Company Name} has a long history of delivering reliable and durable Smt Soldering Machines to the market, and the new model is no exception. Built with high-quality materials and precision engineering, the machine is designed to withstand the rigors of continuous use and deliver consistent performance over its lifespan, making it a wise investment for electronics manufacturers.The introduction of this new revolutionary Smt Soldering Machine further solidifies {Company Name}'s position as a leader in the industry. The company's ability to constantly innovate and deliver cutting-edge solutions to the market sets it apart from its competitors and underscores its dedication to meeting the evolving needs of its customers.In addition to its commitment to technological advancement, {Company Name} prides itself on providing exceptional customer service and support. The company's team of experts is readily available to assist customers with any inquiries, offering comprehensive technical assistance and guidance to ensure the smooth operation of their machinery.With the unveiling of its new revolutionary Smt Soldering Machine, {Company Name} continues to set the standard for excellence in the industry. By combining advanced technology, user-friendly design, and superior reliability, the company has once again demonstrated its ability to deliver game-changing solutions that drive efficiency and productivity for its customers.As the global demand for high-quality electronics continues to grow, the need for advanced manufacturing equipment, such as the new Smt Soldering Machine from {Company Name}, will only become more pronounced. With its unrivaled expertise and commitment to innovation, {Company Name} is well-positioned to meet this demand and remain a driving force in the Smt Soldering Machine industry for years to come.

Domestic PCB Assembly SMT Grows Strong in China as Electronics Manufacturing Flourishes

China SMT PCB Assembly: Boosting Electronics Manufacturing in ChinaChina has emerged as a global manufacturing powerhouse, playing a pivotal role in various industries. One such industry is electronics manufacturing, and one of the key players in this sector is China PCB Assembly SMT. With a strong commitment to quality and advanced technology, this company has succeeded in establishing itself as a reliable partner for electronics manufacturing needs.China PCB Assembly SMT is a leading provider of printed circuit board assembly (PCBA) services in China. The company offers a wide range of services, including surface mount technology (SMT), through-hole technology (THT), and mixed technology assembly. Their state-of-the-art facilities are equipped with advanced machinery, ensuring precise and efficient assembly processes.With a focus on high-quality production, China PCB Assembly SMT adheres to strict quality control measures throughout every stage of the manufacturing process. The company has obtained ISO 9001 certification, demonstrating its commitment to meeting international quality standards. These stringent quality control measures ensure that each product delivered by China PCB Assembly SMT meets or exceeds customer expectations.Apart from quality, China PCB Assembly SMT also places great emphasis on technological innovation. By investing in the latest manufacturing equipment and employing a highly skilled workforce, they are able to stay at the forefront of technological advancements in the industry. This continuous integration of new technologies enables China PCB Assembly SMT to offer efficient, cost-effective, and cutting-edge assembly solutions to their clients.One of the biggest advantages of partnering with China PCB Assembly SMT is their focus on providing comprehensive services. The company offers complete turnkey solutions, starting from PCB design and layout, to component sourcing, assembly, and testing. This end-to-end approach streamlines the manufacturing process and saves clients time and resources.China PCB Assembly SMT serves a wide array of industries, including consumer electronics, telecommunications, automotive, medical devices, and industrial equipment. With their extensive experience and expertise, they are able to cater to the unique requirements of each industry, ensuring that the final products are of the highest quality.In order to meet the growing demands of the global market, China PCB Assembly SMT has also expanded its production capabilities. They have established larger manufacturing facilities and implemented automated production lines to increase productivity. This expansion allows them to handle large-scale orders while maintaining the same level of quality and efficiency.Furthermore, China PCB Assembly SMT is committed to environmental sustainability. They have implemented eco-friendly manufacturing practices and utilize recyclable materials whenever possible. By prioritizing sustainability, the company not only reduces its environmental impact but also aligns with the changing demands of global markets that seek environmentally conscious electronics manufacturers.China PCB Assembly SMT's dedication to quality, technology, and comprehensive services has earned them recognition and trust from both domestic and international clients. Their commitment to meeting customer requirements, along with their competitive pricing, has made them one of the leading PCB assembly service providers in China.In conclusion, China PCB Assembly SMT plays a significant role in boosting electronics manufacturing in China. With their state-of-the-art facilities, advanced technology, and commitment to quality, the company has become a trusted partner for PCB assembly needs. By offering comprehensive services and continuously investing in innovation, China PCB Assembly SMT is well-positioned to meet the evolving demands of the global electronics market.

Complete Guide to Surface Mount PCB Assembly Services

[Company Name] Announces Expansion of Surface Mount PCB Assembly[City, State] – [Date] – [Company Name], a leading provider of electronic manufacturing services, is excited to announce the expansion of its surface mount PCB assembly capabilities. With the investment in state-of-the-art equipment and technology, [Company Name] is poised to meet the growing demand for high-quality, reliable PCB assembly services.[Company Name] has been at the forefront of electronic manufacturing for over [number] years, specializing in offering innovative solutions to meet the evolving needs of its customers. The expansion of its surface mount PCB assembly capabilities is a testament to the company's commitment to staying ahead of the curve and providing its clients with the latest and most advanced manufacturing capabilities.The new equipment and technology introduced by [Company Name] will allow for precision placement of surface mount components on PCBs, resulting in improved accuracy, reliability, and efficiency. This will enable [Company Name] to offer a wider range of PCB assembly services to its customers, catering to a diverse set of needs and requirements."We are thrilled to announce the expansion of our surface mount PCB assembly capabilities," said [Spokesperson] of [Company Name]. "This investment represents our dedication to providing our customers with the highest quality manufacturing services. With the latest equipment and technology at our disposal, we can ensure that our PCB assembly processes are more advanced than ever, resulting in superior products for our clients."The expanded surface mount PCB assembly capabilities at [Company Name] will benefit a wide range of industries, including aerospace, automotive, consumer electronics, medical devices, and more. The company is well-positioned to serve the needs of clients in these sectors, delivering solutions that meet their specific requirements and standards.In addition to the expansion of its surface mount PCB assembly capabilities, [Company Name] continues to emphasize its commitment to quality, reliability, and customer satisfaction. The company adheres to strict quality control measures throughout the manufacturing process, ensuring that every product that leaves its facility meets the highest standards of excellence.Furthermore, [Company Name] takes a customer-centric approach to its services, working closely with clients to understand their unique needs and preferences. This collaborative approach allows [Company Name] to offer tailored solutions that address the specific challenges and goals of each customer, fostering strong and long-lasting partnerships.As [Company Name] continues to expand its surface mount PCB assembly capabilities, the company remains dedicated to staying at the forefront of electronic manufacturing. By investing in the latest technology and equipment, [Company Name] is well-equipped to meet the evolving demands of the industry and provide its customers with the most advanced and reliable solutions available.To learn more about [Company Name] and its electronic manufacturing services, visit [company website] or contact the company directly at [contact information].About [Company Name]:[Company Name] is a leading provider of electronic manufacturing services, specializing in PCB assembly, prototyping, testing, and more. With over [number] years of experience, [Company Name] is committed to delivering innovative and reliable solutions to meet the unique needs of its customers. The company's state-of-the-art facility and dedicated team of professionals ensure the highest levels of quality and customer satisfaction.

Dip Plug-In Process Factory: Streamlining the Manufacturing Process for Optimal Results

Dip Plug-In Process Factory: Revolutionizing Manufacturing InnovationIn today's fast-paced world, the constant demand for innovation and efficiency has never been higher. Industries are constantly seeking new ways to streamline their manufacturing processes and develop cutting-edge technologies. In line with this trend, a groundbreaking Plug-In Process Factory has emerged, poised to transform the industry, thanks to its revolutionary manufacturing capabilities.The newly established Dip Plug-In Process Factory aims to redefine conventional manufacturing processes by implementing state-of-the-art technologies. This cutting-edge factory is backed by an experienced team of highly skilled engineers and technicians who strive to develop innovative manufacturing solutions for various industries.Dip Plug-In Process Factory prides itself on its ability to provide end-to-end manufacturing solutions tailored to each client's specific needs. From the initial design phase to production and final assembly, this factory offers a seamless process that ensures optimal manufacturing efficiency and top-notch quality.One of the key advantages that sets Dip Plug-In Process Factory apart from its competitors is its utilization of plug-in manufacturing processes. This innovative approach allows for greater flexibility and adaptability during the production stage. With plug-in technology, manufacturers can easily modify and customize their processes to accommodate changes in product design, market demand, or unexpected challenges.By implementing plug-in manufacturing processes, Dip Plug-In Process Factory helps businesses save valuable time and resources. The ability to make quick adjustments along the production line ensures that companies can respond swiftly to market trends and customer demands, gaining a competitive edge.Moreover, Dip Plug-In Process Factory understands the importance of sustainability in today's manufacturing landscape. The factory places a strong emphasis on eco-friendly practices, integrating environmentally conscious policies into their manufacturing processes. From energy-efficient machinery to waste reduction strategies, this factory strives to minimize its environmental impact while maximizing production capabilities.Dip Plug-In Process Factory's commitment to sustainability extends beyond their manufacturing practices. They actively engage in research and development to explore cleaner and more sustainable materials for use in production. By continuously seeking innovative solutions, Dip Plug-In Process Factory aims to contribute to a greener, more sustainable future for the manufacturing industry.Furthermore, the factory also offers comprehensive training and consulting services, providing clients with the tools and knowledge necessary to optimize their manufacturing processes. By partnering with Dip Plug-In Process Factory, businesses gain access to a wealth of expertise and insights into enhancing their production capabilities.With a proven track record of successful projects across diverse industries, Dip Plug-In Process Factory has established itself as a trusted partner for businesses aspiring to revolutionize their manufacturing processes. Through their unwavering commitment to innovation, sustainability, and efficiency, this factory has become a driving force behind the transformation of the manufacturing landscape.In conclusion, Dip Plug-In Process Factory is revolutionizing the manufacturing industry through its state-of-the-art plug-in manufacturing processes. With a focus on innovation, sustainability, and customization, this factory offers end-to-end manufacturing solutions tailored to each client's needs. By embracing plug-in technology, Dip Plug-In Process Factory enables businesses to adapt quickly to market changes and streamline their production processes. With a dedicated team of experts, a commitment to sustainability, and comprehensive training and consulting services, this factory is leading the way towards a more efficient and eco-friendly future for manufacturing.

Exploring the Thriving Electronic Assembly Industry: A Comprehensive Overview

[News Headline]Electronic Assembly Industry Expecting Significant Growth Opportunity in the Coming Years[News Content]The Electronic Assembly industry is set to experience substantial growth in the foreseeable future, driven by advancements in technology, increasing demand for electronic devices, and a growing emphasis on connectivity and automation. With the market projected to expand at a rapid pace, several key players, including {}, are well-positioned to capitalize on this opportunity.The Electronic Assembly industry refers to the process of manufacturing and piecing together electronic components to create functional electronic devices, such as smartphones, laptops, televisions, and more. This sector plays a vital role in the overall electronics industry, providing the necessary expertise and infrastructure for the production of these complex devices.Technological advancements have been a major catalyst for the growth of the Electronic Assembly industry. As consumer preferences shift towards smarter and more sophisticated electronic devices, companies are constantly investing in research and development to stay ahead of the curve. The ongoing development of innovative technologies like 5G, Internet of Things (IoT), artificial intelligence (AI), and virtual reality (VR) has created a huge demand for electronic assemblies that can support these functionalities.Additionally, the global electronics market has witnessed a surge in demand for electronic devices due to increased urbanization, rising disposable incomes, and changing lifestyles. As a result, manufacturers in the Electronic Assembly industry are ramping up production capacities to meet the growing needs of consumers. This has led to a robust market outlook with promising growth potential.One such player in the Electronic Assembly industry is {}, a leading company specializing in electronic assembly services. With extensive experience and a state-of-the-art manufacturing facility, {} is well-equipped to cater to the increasing demands of the market. The company offers a wide range of services, including printed circuit board assembly (PCBA), surface mount technology (SMT), and electronic manufacturing services (EMS), among others.{} has been at the forefront of technological advancements, incorporating cutting-edge equipment and processes into its manufacturing operations. This allows the company to deliver high-quality electronic assemblies that meet the stringent requirements of its clients. By leveraging its expertise and capabilities, {} aims to capture a significant share of the growing Electronic Assembly market.The COVID-19 pandemic has further emphasized the need for reliable and efficient electronic devices. As remote work, online education, and telemedicine become the new norm, electronic assemblies play a crucial role in facilitating these activities. The pandemic has accelerated the adoption of digital solutions and led to an increased demand for electronic devices across various sectors. This scenario, coupled with the anticipated recovery of economies worldwide, presents a golden opportunity for {} and other companies in the Electronic Assembly industry.Looking ahead, the Electronic Assembly industry is expected to witness continued growth, driven by factors such as technological advancements, increasing demand for electronic devices, and the ongoing trend towards connectivity and automation. As the market expands, companies like {} are well-positioned to leverage their expertise and cater to the evolving needs of consumers.In conclusion, the Electronic Assembly industry is poised for significant growth in the coming years. With increasing reliance on electronic devices and technological advancements driving the market, companies like {} have the potential to thrive and deliver innovative electronic assemblies. As the world becomes increasingly connected, the Electronic Assembly industry will play a crucial role in shaping the future of technology and connectivity.

Circuit Card Assembly Factory: A Hub of Advanced Electronics Manufacturing

[Company Name] Opens State-of-the-Art Circuit Card Assembly Factory[City, State] - [Company Name], a leading provider of cutting-edge technology solutions, has recently unveiled its new state-of-the-art circuit card assembly factory in [City, State]. The facility marks a significant milestone in the company's expansion plans and is set to revolutionize the production and assembly of circuit cards.Spanning over [number] square feet, the newly built circuit card assembly factory is equipped with the latest cutting-edge technologies and advanced machinery. With a production capacity of [number] circuit cards per day, the facility is designed to meet the increasing demand for high-quality circuit card assembly solutions in various industries, including automotive, telecommunications, aerospace, and consumer electronics.[Company Name] has always been at the forefront of innovation and aims to deliver superior products that exceed customer expectations. The new factory is a testament to the company's commitment to excellence and its persistent efforts to provide best-in-class circuit card assembly services.The facility boasts a highly trained and skilled workforce, consisting of engineers, technicians, and quality control professionals who ensure the seamless assembly of circuit cards. Equipped with expertise in the latest manufacturing techniques and utilizing advanced equipment, the team guarantees the highest level of quality and reliability.The circuit card assembly process in the factory follows a meticulous and robust procedure to ensure maximum efficiency and accuracy. From component placement and solder paste printing to inspection and testing, each stage is executed with precision and attention to detail. The factory adheres to stringent quality standards and complies with all applicable industry regulations to deliver products that are unmatched in their quality and performance.By investing in state-of-the-art machinery and automated systems, [Company Name] can achieve enhanced precision, increased production speed, and reduced costs. The factory is equipped with cutting-edge robotics and computerized systems that optimize the assembly process, enabling quicker turnaround times without compromising on quality.One of the key features of the facility is its commitment to environmental sustainability. [Company Name] has incorporated green practices throughout the factory, focusing on minimizing waste, conserving energy, and adopting eco-friendly manufacturing processes. The company's dedication to sustainability aligns with its vision to create a greener future while providing innovative circuit card assembly solutions to its customers.The inauguration of the circuit card assembly factory reinforces [Company Name]'s position as a trusted partner for businesses looking for high-quality circuit cards. With the capacity to scale production based on customer requirements, the company is well-positioned to cater to the growing market demand for reliable and technologically advanced circuit cards.The new factory also signifies the company's commitment to local job creation and economic growth. By setting up the facility in [City, State], [Company Name] has created numerous employment opportunities, contributing to the growth of the local economy and fostering innovation within the region.As [Company Name] continues its expansion plans, the circuit card assembly factory empowers the company to further strengthen its market position and expand its reach globally. The facility is poised to drive innovation, provide exceptional products, and deliver unparalleled customer experiences.About [Company Name]:[Company Name] is a leading global provider of cutting-edge technology solutions for various industries. With a focus on innovation, quality, and customer satisfaction, the company is committed to delivering superior products and services that shape the future. [Company Name] operates in [number] countries and caters to a diverse range of clients, including multinational corporations and small businesses.

Benefits of Using High-Quality Gold Wire Bonding for Electronics Applications

High-Quality Gold Wire Bonding Technology Revolutionizes Electronics IndustryGold wire bonding has long been a cornerstone of the electronics industry, providing a reliable and efficient method for connecting semiconductor chips to the packaging substrate. This critical process is essential for the production of a wide range of electronic devices, from smartphones and tablets to automotive electronics and medical devices. However, the demand for higher performance and reliability in electronic devices has driven the need for improvements in gold wire bonding technology. The introduction of high-quality gold wire bonding by {Company Name}, a leading provider of advanced packaging and interconnect solutions, is set to revolutionize the industry and meet these growing demands.{Company Name} has been at the forefront of innovation in the electronics industry for over 30 years, developing cutting-edge solutions to meet the ever-evolving needs of the market. With a strong focus on research and development, the company has continuously invested in advancing its wire bonding technology to deliver high-quality and high-performance solutions to its customers. The new high-quality gold wire bonding technology represents the latest achievement in this ongoing commitment to innovation.The key to {Company Name}'s high-quality gold wire bonding technology lies in its advanced manufacturing processes and materials. The company has developed proprietary techniques for producing ultra-fine gold wires with exceptional purity and consistency. These wires are then bonded to semiconductor chips with unparalleled precision and reliability, ensuring robust connectivity and signal integrity. This level of quality is essential for meeting the rigorous performance and reliability requirements of modern electronic devices.In addition to its superior performance, {Company Name}'s high-quality gold wire bonding technology also offers significant cost advantages. The company's advanced manufacturing processes allow for higher throughput and yield, resulting in lower production costs for its customers. Furthermore, the exceptional reliability of the bonding process minimizes the risk of in-field failures, reducing warranty and support costs for electronic device manufacturers.The impact of {Company Name}'s high-quality gold wire bonding technology is already being felt across the electronics industry. Leading semiconductor manufacturers have embraced this technology to enhance the performance and reliability of their products, giving them a competitive edge in the market. Electronic device manufacturers, in turn, are benefiting from the improved quality and cost-efficiency of their products, driving greater customer satisfaction and loyalty.Beyond its immediate impacts, {Company Name}'s high-quality gold wire bonding technology is also paving the way for the development of next-generation electronic devices. As the demand for smaller, faster, and more reliable electronics continues to grow, the need for advanced interconnect solutions becomes increasingly critical. The exceptional performance and reliability of {Company Name}'s gold wire bonding technology make it well-suited for meeting these future demands, opening up new possibilities for innovation in the electronics industry.Looking ahead, {Company Name} remains dedicated to pushing the boundaries of possibility in the electronics industry. With its high-quality gold wire bonding technology serving as a testament to its commitment to excellence, the company is poised to continue driving innovation and shaping the future of electronic devices. By delivering advanced packaging and interconnect solutions that exceed the expectations of its customers, {Company Name} is cementing its position as a leader in the industry and a driving force for progress.

Optimized SEO Title: An In-Depth Look into Efficient PCB Assembly

Title: Cutting-Edge PCB Assembly Solutions Revolutionize the Electronics IndustryIntroduction:In today's rapidly evolving electronics industry, Printed Circuit Board (PCB) assembly is a critical process that ensures the seamless integration of components and the efficient functioning of electronic devices. One company, (delete brand name), has emerged as a leading provider of top-notch PCB assembly solutions, revolutionizing the industry with their cutting-edge technologies and unwavering commitment to quality. This article delves into the company's capabilities, their state-of-the-art facilities, and their significant contributions to the electronics manufacturing sector.1. A Legacy of Excellence:With over (delete number) years of industry experience, (delete brand name) has established itself as a trusted name in the field of PCB assembly. Their dedication to innovation, attention to detail, and customer-centric approach have enabled them to partner with some of the world's most renowned brands. The company's skilled workforce and robust supply chain management ensure that products are delivered on time and adhere to the strictest quality standards.2. State-of-the-Art Facilities:The core strength of (delete brand name) lies in their state-of-the-art manufacturing facilities equipped with advanced machinery and cutting-edge technologies. Their PCB assembly lines are designed to handle high volumes without compromising on precision and accuracy. The company's cleanroom environments minimize contamination risks, allowing for the assembly of highly sensitive electronic components. Additionally, (delete brand name) invests consistently in research and development, staying ahead of the curve in an ever-evolving market.3. Comprehensive Range of Services:(delete brand name) offers a comprehensive range of PCB assembly services, catering to industries such as consumer electronics, automotive, medical devices, aerospace, and telecommunications. From prototype assembly to full-scale production, the company meticulously meets the needs of each client. Their team of experts works closely with customers, providing design review, component sourcing, and cost-effective assembly solutions. This collaborative approach ensures that the end product meets both technical specifications and market demands.4. Emphasis on Quality Assurance:Quality is at the heart of (delete brand name)'s operations. The company follows stringent quality control measures at every stage of the PCB assembly process. Their highly trained quality assurance professionals conduct rigorous inspections and tests to ensure that each assembled board adheres to the highest standards. By employing advanced inspection techniques such as automated optical inspection (AOI) and X-ray testing, (delete brand name) guarantees product reliability and minimizes the risk of defects.5. Commitment to Environmentally Friendly Practices:In an era where environmental sustainability is paramount, (delete brand name) embeds environmentally friendly practices into their manufacturing processes. The company adheres to global standards and regulations like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment). By minimizing waste generation, optimizing energy consumption, and recycling materials, (delete brand name) reduces their carbon footprint and contributes to a greener future.6. Industry Recognition and Awards:The prowess of (delete brand name) in PCB assembly has been recognized through numerous industry accolades. Awards for operational excellence, innovation, and superior customer service highlight their commitment to delivering high-quality solutions. Such recognitions reinforce (delete brand name)'s position as an industry leader and further inspire their dedication to continuous improvement.Conclusion:(delete brand name) has emerged as a frontrunner in the electronics industry, providing top-notch PCB assembly solutions renowned for their quality, precision, and technological expertise. Through their state-of-the-art facilities, comprehensive services, and commitment to sustainability, the company continues to redefine industry standards. With an unwavering focus on excellence, (delete brand name) paves the way for technological advancements and contributes significantly to the growth and success of the electronics manufacturing sector.

Top Digital Electronics from China: Latest News and Updates

China's Digital Electronics industry has seen a significant boost in recent years, with the demand for digital products and technology on the rise. This trend has led to the emergence of several leading companies in the sector, one of them being the rapidly growing company.Established in 2005, the company has quickly made a name for itself in the highly competitive digital electronics market. Specializing in the manufacturing and distribution of a wide range of digital products, the company has established itself as a leader in the industry.One of the key factors that have contributed to the company's success is its commitment to innovation and technology. The company has continuously invested in research and development, ensuring that its products are at the forefront of technological advancements. This commitment to innovation has allowed the company to stay ahead of the competition and meet the ever-changing demands of the digital electronics market.Furthermore, the company has also focused on building strong partnerships with leading technology companies and manufacturers. By collaborating with these industry leaders, the company has been able to access the latest technologies and incorporate them into its products, further enhancing its competitive edge in the market.In addition to its technological prowess, the company has also placed a strong emphasis on quality and reliability. Its products are known for their high-quality construction and durability, making them highly sought after by consumers and businesses alike. This commitment to quality has earned the company a reputation for excellence in the industry.Moreover, the company has also expanded its reach beyond the domestic market, establishing a strong presence in international markets. By leveraging its strong distribution network and strategic partnerships, the company has been able to export its products to numerous countries around the world, further solidifying its position as a global player in the digital electronics industry.Despite its rapid growth and success, the company remains committed to its core values of integrity, customer satisfaction, and social responsibility. It has implemented strict quality control measures to ensure that its products meet the highest standards, and has also taken steps to minimize its environmental impact through sustainable manufacturing practices.Looking ahead, the company is poised to capitalize on the continued growth of the digital electronics market. With its unwavering commitment to innovation, quality, and customer satisfaction, the company is well-positioned to maintain its leadership in the industry and continue its upward trajectory.As China's digital electronics industry continues to flourish, companies like this one are expected to play a pivotal role in shaping the future of the market. With its strong track record and dedication to excellence, the company is set to remain a key player in the industry for years to come.