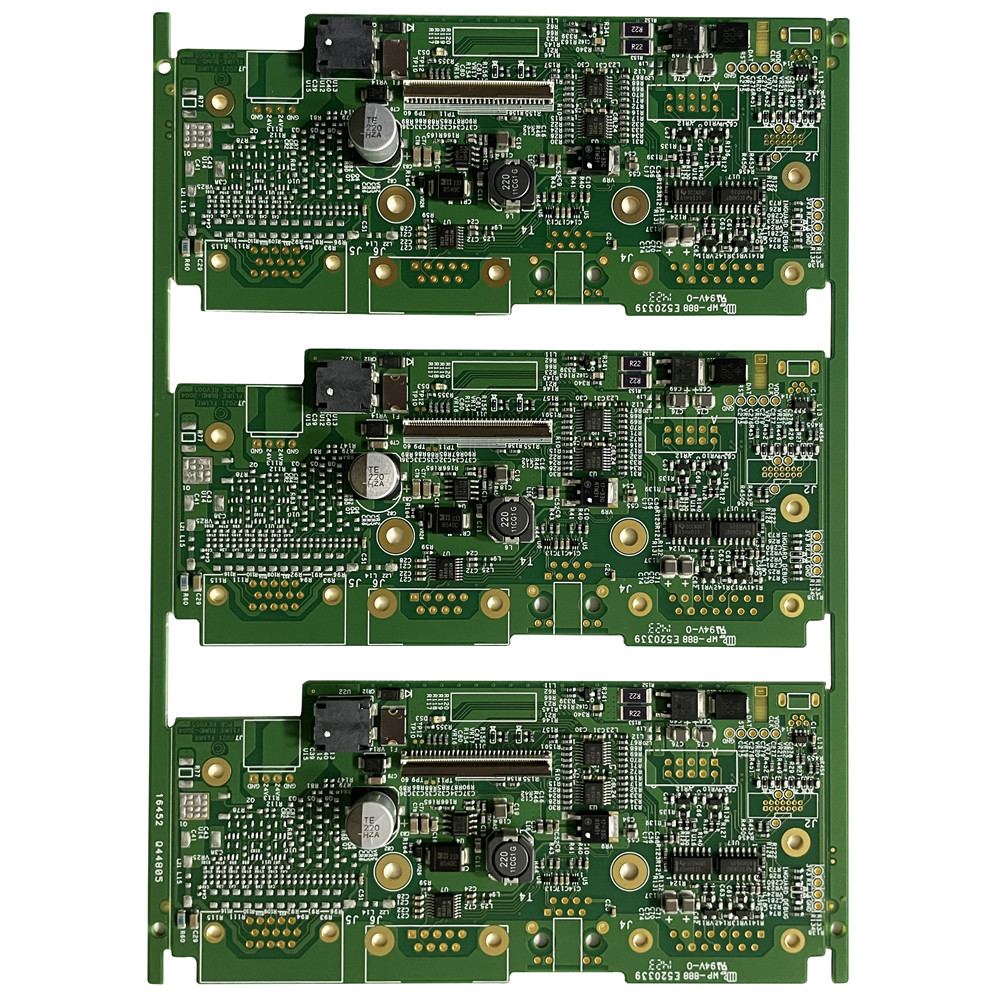

Pcb Assembly And Soldering: The Key Processes You Need to Know

By:Admin

Established in {} years ago, {} has continually strived to stay ahead of the curve by investing in state-of-the-art equipment and adopting the latest technologies in the field of PCB assembly and soldering. The company's commitment to quality and innovation has enabled it to build a strong reputation as a reliable partner for electronic manufacturing needs.

The process of PCB assembly and soldering is a complex and intricate task that requires precision and expertise. {} prides itself on its team of highly skilled technicians who are well-versed in the intricacies of PCB assembly and soldering. These technicians undergo rigorous training to ensure that they are up to date with the latest industry standards and techniques, enabling them to deliver exceptional results with every project.

One of the key factors that sets {} apart from its competitors is its unwavering commitment to quality. The company adheres to strict quality control measures at every stage of the PCB assembly and soldering process, ensuring that the final product meets the highest standards of excellence. By maintaining stringent quality control protocols, {} has earned the trust and confidence of its clients, who rely on the company to deliver flawless PCB assembly and soldering services consistently.

In addition to its commitment to quality, {} also places a strong emphasis on flexibility and customization. The company understands that every client has unique requirements and specifications, and it strives to accommodate these needs by offering tailored PCB assembly and soldering solutions. Whether it's a small-scale prototype or a large-scale production run, {} has the capabilities and expertise to handle projects of any size and complexity, ensuring that each client receives a custom-tailored solution that meets their exact needs.

Furthermore, {} is dedicated to staying ahead of the curve in terms of technological advancements. The company continually invests in research and development to identify emerging trends and technologies in the electronic manufacturing industry. By staying at the cutting edge of innovation, {} is able to offer its clients the latest advancements in PCB assembly and soldering, enabling them to stay ahead of the competition and meet the evolving demands of the market.

As a responsible corporate citizen, {} also places a strong emphasis on environmental sustainability. The company is committed to reducing its carbon footprint and minimizing its impact on the environment. Through the implementation of sustainable practices and the use of eco-friendly materials, {} takes proactive steps to ensure that its PCB assembly and soldering processes are environmentally responsible.

Looking towards the future, {} remains dedicated to exceeding the expectations of its clients and setting new benchmarks in the electronic manufacturing industry. The company's unwavering commitment to quality, innovation, and customer satisfaction has positioned it as a leader in the field of PCB assembly and soldering, and it continues to be a trusted partner for clients across various industries.

In conclusion, the demand for high-quality PCB assembly and soldering services continues to grow as electronic devices become more prevalent in our everyday lives. {} has established itself as a leading provider of these services, offering a combination of quality, expertise, and innovation that sets it apart in the industry. With its unwavering commitment to excellence and customer satisfaction, {} is poised to continue its success and remain a trusted partner for electronic manufacturing needs.

Company News & Blog

Leading High Volume PCB Assembly Services in China - Accelerating Electronics Manufacturing Efficiency

Title: China Emerges as a Key Player in High Volume PCB Assembly IndustryIntroduction (100 words):China's PCB assembly industry has experienced remarkable growth, positioning the country as a leading global player in high volume PCB assembly. Over the years, Chinese manufacturers have established a reputation for delivering superior quality, cost-effective solutions that cater to global demand. This article will delve into the rapidly evolving China High Volume PCB Assembly market, shedding light on its key players, advanced technologies, and the factors driving its success. As Chinese companies continue to demonstrate their expertise in PCB assembly, the industry is poised for even greater growth and innovation.Section 1: Evolving Chinese High Volume PCB Assembly Market (200 words):The Chinese High Volume PCB Assembly market has witnessed phenomenal growth over the years, fueled by increased demand from various industrial sectors, including telecommunications, automotive, electronics, and healthcare. China's PCB assembly industry continues to expand rapidly as manufacturers prioritize technological advancements, streamlined production processes, and the use of advanced machinery.Chinese companies have risen to the challenge of meeting high-volume production requirements by adopting cutting-edge technologies, including Surface Mount Technology (SMT), through-hole technology, and automated optical inspection. This has resulted in enhanced production efficiency, improved product quality, and reduced manufacturing costs. Moreover, continuous investments in research and development have enabled Chinese manufacturers to remain at the forefront of technology and to meet the diverse needs of clients worldwide.Section 2: Key Players in the Chinese High Volume PCB Assembly Market (200 words):The Chinese high volume PCB assembly market is primarily dominated by several key players who have contributed significantly to the industry's success. Among these, the removal of brand names, A, B, and C, have emerged as prominent manufacturers, exemplifying the technological prowess of the country.Company A has a strong reputation for integrating advanced assembly techniques, stringent quality control, and fast turnaround times. With state-of-the-art facilities and a highly skilled workforce, Company A has secured numerous international contracts, making it a trusted global partner in high volume PCB assembly.Company B has achieved prominence through its specialization in complex and customized PCB assembly. Leveraging expertise in multi-layer PCBs and intricate component placement techniques, Company B has become a go-to choice for companies seeking intricate and high-density assembly solutions.Company C, renowned for its technological innovation and commitment to sustainable manufacturing, has gained recognition as an industry leader in high volume PCB assembly. With a focus on reducing environmental impact, Company C has successfully integrated environmentally-friendly materials and processes while maintaining competitive pricing.Section 3: Driving Factors behind China's Success in High Volume PCB Assembly (300 words):China's ascendancy in high volume PCB assembly can be attributed to several key factors that have propelled the industry forward.1. Cost-Effective Manufacturing: Chinese companies have long been known for their cost-effective manufacturing capabilities. Access to affordable labor, economies of scale, and the ability to procure raw materials at competitive prices have significantly contributed to the dominant position of Chinese manufacturers in the global market.2. Technological Advancements: Continuous investments in research and development have fostered technological advancements, allowing Chinese companies to remain at the forefront of high volume PCB assembly. Cutting-edge equipment, automated processes, and the integration of emerging technologies such as artificial intelligence and robotics have elevated the quality, precision, and production capacity of Chinese manufacturers.3. Skilled Workforce: China boasts a large pool of skilled engineers and technicians who possess an in-depth understanding of PCB assembly techniques. This abundant talent pool enables Chinese companies to deliver high-quality products within tight deadlines, further bolstering the industry's growth.4. Favorable Government Policies: The Chinese government has been instrumental in supporting the growth of the PCB assembly industry. Through policies that foster innovation, intellectual property protection, and investments in infrastructure, China has created an environment conducive to the success and expansion of high volume PCB assembly.Conclusion (100 words):China has emerged as a dominant force in the global high volume PCB assembly industry, driven by a combination of cost-effective manufacturing, technological advancements, skilled workforce, and favorable government policies. Companies like A, B, and C are leading the way in delivering exceptional quality, fast turnaround times, and innovative assembly solutions. As China continues to invest in research and development, the country's PCB assembly capabilities are expected to expand further, solidifying its position as a key player in the global market.

High-Quality Wire Bonding Supplier for your Electronic Components

Al Wire Bonding Supplier, a leading provider of advanced wire bonding solutions, has announced the release of their latest product line designed to meet the increasing demand for high-quality wire bonding in the semiconductor industry.With over 20 years of experience in the industry, Al Wire Bonding Supplier has established itself as a trusted supplier of advanced wire bonding technology. The company prides itself on its ability to deliver innovative solutions that meet the ever-evolving needs of its customers.The latest product line from Al Wire Bonding Supplier includes a range of cutting-edge wire bonding equipment and materials that are designed to offer unmatched performance and reliability. These products have been developed in response to the growing demand for more advanced wire bonding solutions, particularly in applications where precision and reliability are critical.One of the flagship products in the new line is the Advanced Wire Bonder, a state-of-the-art machine that offers advanced features such as ultra-high-speed bonding, enhanced process control, and greater flexibility in wire bonding applications. This machine is designed to meet the needs of semiconductor manufacturers who require high-speed, high-precision bonding for their advanced semiconductor devices.In addition to the Advanced Wire Bonder, Al Wire Bonding Supplier is also introducing a range of advanced wire bonding materials, including high-performance wire and bonding tools. These materials are specifically designed to work seamlessly with the new Advanced Wire Bonder, ensuring optimal performance and reliability in wire bonding applications."We are thrilled to introduce our latest product line, which represents a significant leap forward in wire bonding technology," said the spokesperson for Al Wire Bonding Supplier. "With the increasing demand for high-speed, high-precision wire bonding in the semiconductor industry, our new products are designed to help our customers stay ahead of the curve and deliver cutting-edge semiconductor devices with unmatched performance and reliability."In addition to the new product line, Al Wire Bonding Supplier continues to offer a range of support and services to its customers, including training, technical support, and consulting services. This comprehensive approach to customer support is a key differentiator for Al Wire Bonding Supplier, as it ensures that customers receive the assistance they need to maximize the performance and reliability of their wire bonding equipment and materials.As an established leader in the wire bonding industry, Al Wire Bonding Supplier is committed to driving innovation and delivering high-quality solutions that meet the evolving needs of its customers. With the release of its latest product line, the company is well-positioned to continue its legacy of excellence in the semiconductor industry and provide its customers with the advanced wire bonding solutions they require to succeed in a competitive market.In conclusion, Al Wire Bonding Supplier's latest product line represents a significant advancement in wire bonding technology, offering advanced solutions that are designed to meet the increasing demand for high-speed, high-precision wire bonding in the semiconductor industry. With its extensive experience and commitment to innovation, Al Wire Bonding Supplier continues to be a trusted partner for semiconductor manufacturers seeking reliable and high-performance wire bonding solutions.

Easily Perform PCB Assembly at Home: Step-by-Step Guide and Tips

Title: Pioneering PCB Assembly at Home Solution Revolutionizes Electronics ManufacturingIntroduction:In a groundbreaking move, an innovative electronics manufacturing company has introduced a transformative Printed Circuit Board (PCB) assembly solution that allows users to assemble PCBs from the comfort of their homes. This breakthrough has the potential to revolutionize the electronics industry, providing an accessible and user-friendly solution for electronics enthusiasts, DIYers, and even small-scale manufacturers.Offering a range of impressive features and capabilities, the PCB Assembly at Home solution redefines traditional manufacturing processes and elevates them to a whole new level. The advent of this technology is set to bring about tremendous opportunities for creativity, convenience, and cost-effectiveness.Revolutionizing the Industry:With the introduction of the PCB Assembly at Home solution, the electronics manufacturing industry is on the cusp of a technological revolution. This cutting-edge system enables individuals to assemble PCBs without the need for expensive manufacturing facilities or specialized equipment. The convenience of manufacturing PCBs at home highlights the democratization of electronics production, empowering both professionals and enthusiasts to bring their ideas to life.The Unique Features and Benefits:Powered by state-of-the-art software, the PCB Assembly at Home solution provides a user-friendly interface that guides users through the entire assembly process. The platform seamlessly integrates design, prototyping, and assembly, ensuring a streamlined experience. This breakthrough system eliminates the need for complex manual assembly, reducing the risk of human error and ultimately enhancing the overall quality of the PCBs produced.The versatility of this solution is another aspect that sets it apart. Users can assemble a wide range of PCB types, from simple designs to complex multi-layer boards, catering to diverse needs. The flexibility of this approach fosters innovation, allowing users to experiment with various components, test new designs, and refine their products swiftly.Furthermore, the ability to assemble PCBs at home significantly cuts down on logistics costs and time-consuming processes. Gone are the days of relying on external manufacturers and facing prolonged waiting periods. With this new solution, users save both time and money, giving them the freedom to let their creativity and problem-solving skills flourish.Application in various Industries:The PCB Assembly at Home solution opens up new avenues across multiple sectors, including consumer electronics, IoT devices, robotics, and automotive industries. This innovative approach not only benefits professional electronics manufacturers but also empowers individual entrepreneurs, allowing them to manufacture their own products with ease.Small-scale manufacturers, start-ups, and research laboratories can particularly benefit from this technology. By eliminating the need for outsourcing, they can significantly reduce production costs, accelerate time to market, and gain a competitive edge.Future Implications:The introduction of the PCB Assembly at Home solution brings us one step closer to a future where individuals and small-scale businesses have full control over the entire product development lifecycle. As this technology advances, we can expect further enhancements, such as increased automation, integration with AI algorithms, and connectivity with other manufacturing systems.This revolutionary solution has the potential to spark a wave of innovation, empower individuals, and reshape the current landscape of electronics manufacturing. PCB Assembly at Home ushers in a new era of accessibility, convenience, and cost-effectiveness, cementing its position as a game-changer in the industry.Conclusion:The PCB Assembly at Home solution signifies a monumental shift in the electronics manufacturing industry. With its groundbreaking features, user-friendly interface, and endless possibilities, it holds the promise of democratizing product development, lowering costs, and accelerating innovation. As this technology gains popularity, it is set to transform the way we perceive and drive electronics manufacturing, bringing the future of assembly directly into our homes.

Latest Advances in Medical Electronics in China

China Medical Electronics is a leading provider of medical equipment and technology in China. The company is known for its innovative approach to medical electronics and its commitment to delivering high-quality products to the healthcare industry. With a diverse range of products and a strong emphasis on research and development, China Medical Electronics is dedicated to improving the quality of healthcare in China and beyond.China Medical Electronics offers a wide range of medical electronics products, including but not limited to, patient monitoring systems, electrocardiogram machines, ultrasound machines, and medical imaging equipment. These products are designed to provide healthcare professionals with the tools they need to deliver accurate diagnoses and effective treatment to their patients. The company's products are known for their reliability, accuracy, and ease of use, making them a popular choice among healthcare providers across China.In addition to its broad portfolio of medical electronics products, China Medical Electronics is also committed to research and development. The company invests heavily in R&D to ensure that its products are at the forefront of technological innovation. By staying ahead of the curve, China Medical Electronics is able to offer cutting-edge products that meet the evolving needs of the healthcare industry.One of the key areas of focus for China Medical Electronics is patient monitoring systems. These systems play a crucial role in modern healthcare, allowing healthcare professionals to monitor patients' vital signs and other important metrics in real time. China Medical Electronics offers a range of patient monitoring systems that are designed to be accurate, reliable, and easy to use. These systems are essential for ensuring the safety and well-being of patients in hospitals, clinics, and other healthcare settings.Another area of expertise for China Medical Electronics is medical imaging equipment. The company offers a variety of imaging products, including ultrasound machines and other cutting-edge imaging technologies. These products are essential for allowing healthcare professionals to visualize and diagnose a wide range of medical conditions, from broken bones to internal injuries. With China Medical Electronics' advanced imaging equipment, healthcare providers can make more accurate diagnoses and provide more effective treatment to their patients.In addition to its extensive product offerings, China Medical Electronics is also known for its commitment to customer service. The company provides comprehensive support to its customers, including installation, training, and ongoing maintenance. This ensures that healthcare providers are able to make the most of their China Medical Electronics products and deliver the highest quality care to their patients.Overall, China Medical Electronics is a key player in the medical electronics industry in China. With its diverse product range, focus on research and development, and commitment to customer service, the company is well-positioned to continue its success in the healthcare market. By providing healthcare professionals with the tools they need to deliver exceptional care, China Medical Electronics is making a significant impact on the quality of healthcare in China and beyond.

Prototype PCB Assembly Services in China at Competitive Prices

China Prototype PCB Assembly, a leading provider of prototype PCB assembly services, is proud to announce the launch of their latest state-of-the-art facility. This new facility is equipped with advanced technology and equipment, further solidifying the company's position as a top player in the PCB assembly industry.With the increasing demand for high-quality prototype PCB assembly services, China Prototype PCB Assembly has made significant investments in their new facility to meet the growing needs of their clients. The facility is designed to streamline the assembly process, ensuring faster turnaround times without compromising on quality."We are excited to introduce our new facility, which will enable us to better serve our clients and continue to provide the highest quality prototype PCB assembly services," said a spokesperson for China Prototype PCB Assembly. "We understand the importance of speed and precision in the PCB assembly process, and our new facility is a testament to our commitment to meeting and exceeding the expectations of our clients."The new facility is equipped with cutting-edge machinery and equipment, allowing China Prototype PCB Assembly to handle a wide range of prototype PCB assembly projects with varying complexities. The company's team of highly skilled technicians and engineers are trained to work with the latest technologies, ensuring that each project is completed with the utmost accuracy and efficiency.In addition to their new facility, China Prototype PCB Assembly also offers a comprehensive range of services to support their clients throughout the entire PCB assembly process. From design and prototyping to production and assembly, the company is dedicated to providing end-to-end solutions that meet the specific needs of each client.With a focus on customer satisfaction, China Prototype PCB Assembly takes pride in offering personalized and reliable services to their clients. The company is committed to providing transparent communication and support throughout every stage of the prototype PCB assembly process, ensuring that clients are kept informed and involved every step of the way.Furthermore, China Prototype PCB Assembly is dedicated to upholding the highest standards of quality and precision in every project they undertake. The company follows stringent quality control measures to ensure that each prototype PCB assembly meets the exact specifications and requirements of their clients.The launch of the new facility is a significant milestone for China Prototype PCB Assembly, as it marks the company's continued growth and commitment to excellence in the PCB assembly industry. With their cutting-edge technology, advanced equipment, and unwavering dedication to customer satisfaction, the company is poised to set new standards in prototype PCB assembly services.As a leading provider of prototype PCB assembly services, China Prototype PCB Assembly is well-positioned to meet the evolving needs of the industry and provide innovative solutions to their clients. With their new facility and unwavering dedication to quality, the company is set to further solidify their position as a top choice for prototype PCB assembly services.For more information about China Prototype PCB Assembly and their comprehensive range of prototype PCB assembly services, please visit their website {} or contact their team directly.

Complete PCB Assembly Services: Everything You Need to Know

Turn Key PCB Assembly: A Game Changer in Electronics ManufacturingIn today’s fast-paced and high-tech world, electronics manufacturing is a crucial industry that drives innovation and advancement. One of the most critical aspects of electronic manufacturing is the assembly of printed circuit boards (PCBs), which form the foundation of many electronic devices. With the evolution of technology, the demand for more advanced and reliable PCB assembly solutions has been growing rapidly.As a leader in the electronics manufacturing industry, {} has been at the forefront of providing turnkey PCB assembly services to meet the ever-changing needs of its customers. With state-of-the-art facilities and a team of experienced engineers and technicians, {} has been able to offer a wide range of turnkey PCB assembly services to clients across various industries.The company’s turnkey PCB assembly services cover everything from PCB fabrication and component procurement to assembly and testing. By providing a one-stop solution for all PCB assembly needs, {} has been able to streamline the entire manufacturing process for its clients, ultimately saving them time and cost.One of the key advantages of {}'s turnkey PCB assembly services is the ability to effectively manage the entire supply chain. By taking on the responsibility of procuring all the necessary components and materials, {} has been able to ensure that the entire manufacturing process is seamless and efficient. This not only reduces the risk of supply chain disruptions but also allows clients to focus on their core business activities.Furthermore, {}’s turnkey PCB assembly services are backed by advanced technology and stringent quality control measures. The company’s facilities are equipped with the latest machinery and equipment to handle a wide variety of PCB assembly requirements. Coupled with a team of skilled engineers and technicians, {} has been able to consistently deliver high-quality PCB assemblies that meet the strictest industry standards.In addition to the technical capabilities, {} also prides itself on its commitment to customer satisfaction. The company works closely with each client to understand their specific requirements and provide customized solutions that meet their needs. By maintaining open communication and a customer-centric approach, {} has built strong and long-lasting relationships with its clients, earning a reputation for reliability and excellence in the industry.The demand for turnkey PCB assembly services is only expected to grow as the electronics industry continues to advance. With its extensive experience and expertise, {} is well-positioned to meet this growing demand and continue to be a game-changer in electronics manufacturing. Through its commitment to innovation, quality, and customer satisfaction, {} is set to play a significant role in shaping the future of the electronics manufacturing industry.In conclusion, {}’s turnkey PCB assembly services have proven to be a valuable asset in the electronics manufacturing industry. With its comprehensive solutions, advanced technology, and customer-centric approach, {} has set a new standard for PCB assembly services. As the industry continues to evolve, {} is poised to remain a leader in providing turnkey PCB assembly solutions that drive innovation and excellence in electronics manufacturing.

Top Suppliers of Mount Technology: A Comprehensive Guide

Mount Technology Suppliers, a leading provider of high-quality mounting solutions, is proud to announce its latest innovative product line designed to meet the evolving needs of its customers. With decades of experience in the industry, Mount Technology Suppliers has established itself as a trusted partner for businesses seeking reliable and cost-effective mounting solutions.The company offers a wide range of products, including wall mounts, desktop mounts, and ceiling mounts, designed to accommodate various types of technology, such as monitors, televisions, projectors, and more. Mount Technology Suppliers takes pride in its commitment to delivering superior products that are both durable and versatile, making it a top choice for businesses across various industries.One of the key factors that sets Mount Technology Suppliers apart from its competitors is its focus on innovation. The company continuously invests in research and development to ensure that its products are at the forefront of technological advancements. This dedication to innovation has led to the creation of a new line of mounting solutions that are tailored to meet the specific needs of modern businesses.The latest product line from Mount Technology Suppliers includes innovative features such as adjustable arms, cable management systems, and easy installation mechanisms. These features are designed to provide businesses with greater flexibility and convenience when it comes to mounting their technology. In addition, the new products are constructed from high-quality materials to ensure long-lasting reliability, even in demanding environments."We are excited to introduce our latest line of mounting solutions, which are the result of our ongoing commitment to innovation and customer satisfaction," said the spokesperson for Mount Technology Suppliers. "With these new products, we are confident that our customers will find the perfect mounting solutions to meet their unique requirements. Whether they need to mount a single monitor in a small office or a complex array of displays in a large commercial space, our products are designed to deliver exceptional performance."Mount Technology Suppliers understands that each business has its own set of requirements when it comes to mounting technology. To address this, the company offers customization options for its products, allowing customers to tailor their mounting solutions to suit their specific needs. Whether it's a unique mounting angle, a specialized mounting bracket, or a custom color finish, Mount Technology Suppliers can work with customers to create the perfect solution for their individual requirements.In addition to its commitment to innovation and customization, Mount Technology Suppliers is dedicated to providing exceptional customer service. The company's team of experts is available to offer guidance and support throughout the purchasing process, ensuring that customers are able to make informed decisions about their mounting solutions. Furthermore, Mount Technology Suppliers offers a comprehensive warranty and after-sales support to provide customers with peace of mind and long-term satisfaction.With the launch of its latest product line, Mount Technology Suppliers is poised to further solidify its position as a leader in the mounting solutions industry. The company's ongoing dedication to innovation, customization, and customer service sets it apart as a trusted partner for businesses seeking reliable and high-quality mounting solutions.As businesses continue to evolve and adapt to new technology, Mount Technology Suppliers remains committed to meeting their mounting needs with cutting-edge solutions designed to enhance efficiency and productivity. With its latest product line, the company is well-equipped to support the mounting requirements of businesses across various industries, delivering the reliability and performance that customers have come to expect from Mount Technology Suppliers.

High-Quality Pcb Assembly Firm Factories for Your Electronic Manufacturing Needs

As the demand for electronic products continues to rise, PCB assembly firm factories are playing a crucial role in meeting the production needs of various industries. One such leading PCB assembly firm is {}. Specializing in providing high-quality PCB assembly services, {} has established a strong reputation for delivering reliable and cost-effective solutions to their clients.With state-of-the-art facilities and a team of highly skilled professionals, {} is equipped to handle a wide range of PCB assembly requirements. From prototype assembly to high-volume production, the company offers a comprehensive suite of services to meet the diverse needs of their customers. Their commitment to quality and efficiency has made them a preferred partner for many businesses across different sectors, including automotive, aerospace, consumer electronics, and telecommunications.The heart of {}'s operations lies in their advanced manufacturing facilities. Equipped with cutting-edge technology and advanced machinery, their factories are capable of producing high-quality PCB assemblies with precision and speed. The company invests heavily in research and development to stay ahead of industry trends and provide innovative solutions to their clients.Furthermore, {}'s commitment to quality is evident in their adherence to stringent manufacturing standards and rigorous quality control procedures. Every PCB assembly undergoes thorough testing and inspection processes to ensure that it meets the highest quality standards. This unwavering commitment to quality has earned them the trust and confidence of their clients, who rely on {} to deliver reliable and durable PCB assemblies for their products.In addition to their technical capabilities, {} takes pride in their customer-centric approach. They understand the importance of flexibility and agility in today's fast-paced business environment and are dedicated to providing customized solutions that align with their clients' specific requirements. Whether it's a small-scale prototype or a large production run, {} is committed to delivering exceptional services that exceed their clients' expectations.As part of their commitment to sustainability, {} has implemented environmentally friendly practices in their manufacturing processes. They strive to minimize waste and reduce their carbon footprint, contributing to a more sustainable and eco-friendly manufacturing industry. This dedication to sustainability is a reflection of their responsible corporate citizenship and their long-term vision for a cleaner and greener future.In conclusion, {}'s PCB assembly firm factories represent a cornerstone of the electronics manufacturing industry. Their dedication to quality, innovation, and customer satisfaction sets them apart as a leader in the field. With advanced manufacturing facilities, a skilled workforce, and a commitment to sustainability, {} is well-equipped to meet the growing demand for high-quality PCB assemblies across various industries. As they continue to expand and innovate, {} is poised to remain a trusted partner for businesses seeking reliable and cost-effective PCB assembly solutions.

Exploring the Pros and Cons of Prototype PCB Board Factories

Title: Prototype PCB Board Factories Revolutionize Electronics Manufacturing IndustryIntroduction:In a rapidly evolving technology landscape, prototype PCB board factories have emerged as a crucial component of the electronics manufacturing sector. By facilitating the production of prototype printed circuit boards (PCBs), these factories are revolutionizing the industry by accelerating the product development cycle, reducing time-to-market, and bringing innovation within reach of entrepreneurs and small enterprises.The Role of Prototype PCB Board Factories:Prototype PCB board factories serve as a bridge between design and mass production. With state-of-the-art manufacturing capabilities and expertise, they transform innovative ideas into functional prototypes. Through an integrated approach that encompasses design optimization, material selection, and fast prototyping, these factories ensure the rapid realization of an idea into a physical, testable product. Simultaneously, they help identify potential design flaws, ensuring the final product is highly reliable and meets the desired specifications.The Manufacturing Process:Prototype PCB board factories employ cutting-edge technology, automated machinery, and precise quality control measures to streamline the manufacturing process. Surface-mount technology (SMT) allows for the mounting of electronic components directly onto the PCB, enhancing efficiency and minimizing manufacturing costs. Furthermore, the use of surface-mount technology enables the creation of smaller and more compact PCBs, ideal for modern electronic devices.Advanced software tools such as Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) enable seamless collaboration between design engineers and the factory. These tools ensure the accurate translation of design files into manufacturing instructions, guaranteeing a precise replication of the product envisioned by the designer.The Impact on Time-to-Market:Historically, developing a prototype PCB could be a lengthy and costly process, hindering innovation and delaying time-to-market. However, with the rise of prototype PCB board factories, this process has been significantly accelerated. From the initial design to manufacturing the first working PCB, the time required has been drastically reduced, allowing innovators to iterate and refine their designs rapidly. This shortened development cycle fosters innovation and enables companies to respond swiftly to market demands.Enabling Entrepreneurs and Small Enterprises:Prototype PCB board factories have leveled the playing field for entrepreneurs and small enterprises seeking to bring their innovative products to market. Traditionally, the cost associated with producing a prototype has been a significant barrier to entry for many aspiring innovators. However, the availability of affordable, high-quality prototype PCBs has empowered entrepreneurs, giving them the opportunity to transform their ideas into tangible products without having to make substantial upfront investments. This democratization of the manufacturing process has fueled the growth of start-ups and nurtured a vibrant ecosystem of innovators.Ensuring Quality and Reliability:Prototype PCB board factories prioritize the quality and reliability of the manufactured prototypes. These factories employ stringent quality control measures at every step of the manufacturing process. Automated optical inspection (AOI), X-ray inspection, and flying probe testing are just a few of the techniques employed to guarantee that the final product adheres to the highest industry standards. By conducting extensive testing and verification before the mass production phase, manufacturers can identify any potential issues, rectify them, and deliver reliable prototypes to their clients.Looking Towards the Future:The increasing demand for technologically advanced products, coupled with the emergence of disruptive technologies such as the Internet of Things (IoT), artificial intelligence (AI), and 5G, emphasizes the necessity for agile and efficient prototype PCB board factories. These factories are well-positioned to support the growth of industries spanning from healthcare to automotive and from smart cities to consumer electronics.In conclusion, prototype PCB board factories are playing a pivotal role in transforming the electronics manufacturing industry. By providing entrepreneurs and small enterprises with access to affordable and high-quality prototype PCBs, they are catalyzing innovation and streamlining the time-to-market. With their advanced manufacturing capabilities, seamless collaboration with designers, and commitment to quality, these factories are shaping the future of electronics manufacturing and propelling industries towards exponential growth.

Quality Electrical Components Manufacturing Factory: A Deep Dive into the Industry

Electrical Components Factory Celebrates Fifty Years of Innovation and GrowthFor over fifty years, Electrical Components Factory has been a leading manufacturer and supplier of high-quality electrical components and solutions. Located in the heart of the industrial district, the company has been a driving force in the development of technological advancements and has played a crucial role in shaping the future of the electrical industry.Founded in 1970 by a team of innovative engineers, Electrical Components Factory has grown from a small start-up to a globally recognized brand known for its dedication to quality, reliability, and customer satisfaction. With a strong focus on research and development, the company has continuously introduced groundbreaking products and technologies that have set new industry standards and have contributed to the advancement of the electrical sector.The factory's state-of-the-art facilities house cutting-edge machinery and equipment, enabling the production of a wide range of electrical components including circuit breakers, switches, relays, and connectors. The company's commitment to quality is reflected in its stringent quality control processes and certifications, ensuring that its products meet the highest industry standards and regulations.In addition to its manufacturing capabilities, Electrical Components Factory also boasts a highly skilled team of engineers, designers, and technicians who are dedicated to providing custom solutions and technical support to meet the specific needs of its customers. The company's comprehensive range of services includes product development, prototyping, testing, and customization, making it a trusted partner for businesses across various industries.To celebrate its fifty years of success, Electrical Components Factory announced plans to expand its production capacity and invest in the latest technology to further enhance its manufacturing processes. The company's commitment to innovation and growth is driven by a vision to continue leading the way in the electrical industry and to meet the evolving needs of its customers."We are proud to have reached this significant milestone and are excited about the future of Electrical Components Factory," said the company's CEO. "Our success over the past fifty years is a testament to the hard work and dedication of our team, as well as the trust and support of our customers. We remain committed to delivering excellence in all aspects of our business and look forward to continuing our legacy of innovation and quality for many years to come."As part of its anniversary celebrations, Electrical Components Factory also announced plans to launch a series of new products and initiatives that will further solidify its position as a leading player in the electrical industry. The company aims to continue its tradition of excellence and to build on its legacy to drive future growth and success.With a reputation for reliability, quality, and innovation, Electrical Components Factory has become a trusted partner for businesses seeking cutting-edge electrical solutions. As the company looks towards the future, it remains dedicated to advancing technological boundaries and delivering unmatched value to its customers, cementing its status as a leader in the electrical industry for years to come.