Top Industrial Instrument Suppliers: Providing Quality Products for Your Business Needs

By:Admin

Industrial Instrument Supplier, a leading provider of high-quality industrial instruments and equipment, has recently announced their successful bids for multiple contracts with major companies in the manufacturing, energy, and pharmaceutical industries. These contracts are a significant achievement for the company and demonstrate their commitment to providing top-notch products and services to their clients.

Established in 1995, Industrial Instrument Supplier has built a strong reputation for delivering reliable and innovative instruments to meet the needs of their customers. With a diverse range of products including pressure transmitters, flow meters, level sensors, and temperature controllers, the company has become a trusted partner for businesses across various sectors.

One of the key factors that sets Industrial Instrument Supplier apart from its competitors is its dedication to quality. The company understands the importance of precision and accuracy when it comes to industrial instruments, and they take great care to ensure that all their products meet the highest standards. This commitment to quality has earned Industrial Instrument Supplier the trust of many major corporations in the industry.

In addition to their focus on quality, Industrial Instrument Supplier also prides itself on its ability to provide customized solutions to its clients. The company has a team of experienced engineers and technical experts who work closely with customers to understand their specific requirements and tailor products to meet their needs. This personalized approach has been instrumental in winning the recent contracts with major companies, as it demonstrates Industrial Instrument Supplier's commitment to delivering value-added solutions.

The first of the recent contracts secured by Industrial Instrument Supplier is with a leading manufacturing company in the automotive industry. The company will be supplying a range of pressure transmitters and temperature controllers to support the client's production processes. This contract is a significant win for Industrial Instrument Supplier, as it further solidifies their position as a trusted supplier in the manufacturing sector.

Another major agreement secured by Industrial Instrument Supplier is with a prominent energy company. The company will be providing a comprehensive range of flow meters and level sensors to support the client's operations in the oil and gas sector. This contract is a testament to the company's expertise in delivering solutions to the energy industry and highlights their capability to meet the rigorous demands of this sector.

Furthermore, Industrial Instrument Supplier has also successfully secured a contract with a leading pharmaceutical company. The company will be supplying precision instruments and controllers to support the client's manufacturing processes for pharmaceutical products. This contract underscores Industrial Instrument Supplier's ability to meet the strict regulatory requirements of the pharmaceutical industry and reinforces their position as a reliable partner in this sector.

Overall, the recent contract wins by Industrial Instrument Supplier highlight the company's continued success in providing high-quality instruments and equipment to major companies across various industries. With their focus on quality, customized solutions, and industry expertise, Industrial Instrument Supplier is well-positioned to further expand its presence and continue to be a trusted supplier in the industrial instrumentation market.

Company News & Blog

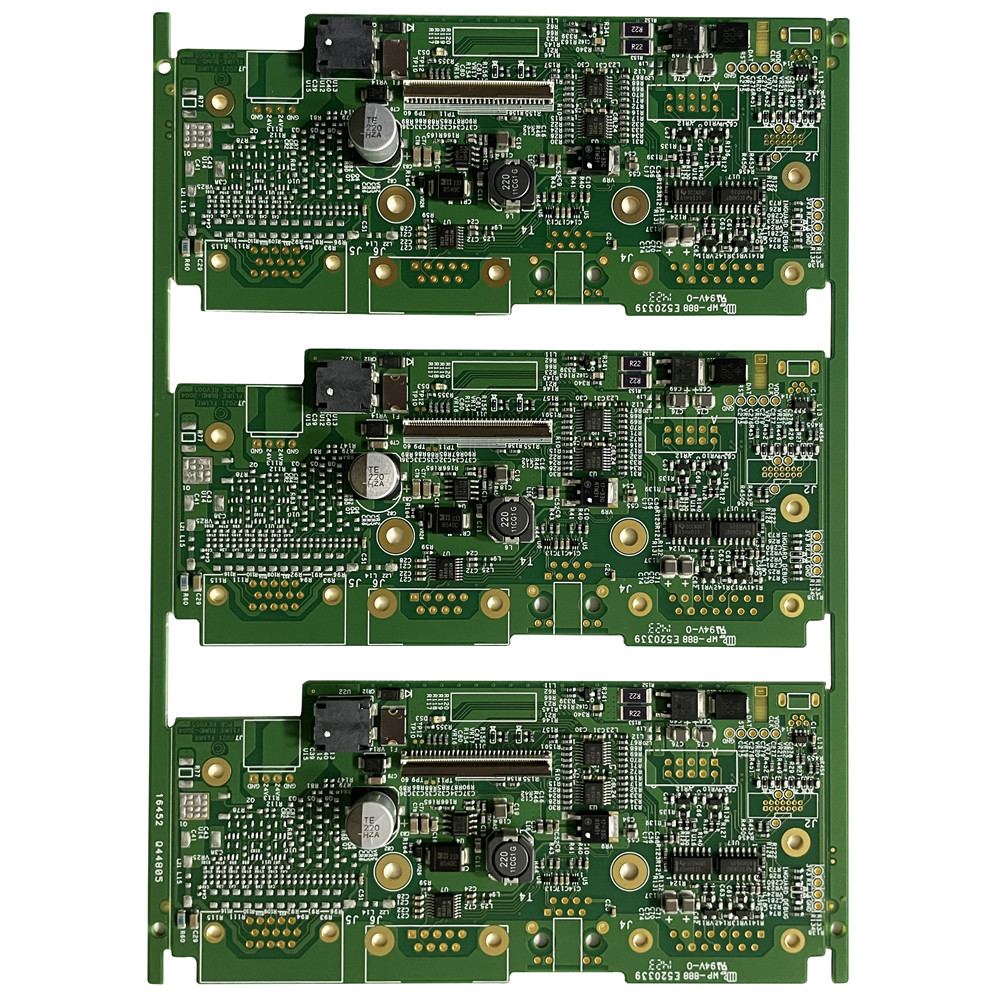

High-quality Flex PCB Assembly Manufacturer for Your Business Needs

Flex PCB Assembly Manufacturer, a leading provider of flexible printed circuit board (PCB) assembly solutions, is making waves in the electronics manufacturing industry with their cutting-edge technology and exceptional customer service.Founded in [year], Flex PCB Assembly Manufacturer has quickly established itself as a trusted partner for companies looking to bring their electronic products to market. The company specializes in the design, assembly, and production of flexible PCBs, which offer a number of advantages over traditional rigid PCBs, including increased durability, flexibility, and space-saving designs.Flex PCB Assembly Manufacturer serves a wide range of industries, including consumer electronics, medical devices, automotive, aerospace, and telecommunications. Their flexible PCBs have been integrated into a variety of products, from wearable devices to automotive sensors, demonstrating the versatility and reliability of their assembly solutions.One of the key differentiators for Flex PCB Assembly Manufacturer is their commitment to innovation and continuous improvement. The company invests heavily in research and development to stay abreast of the latest technological advancements and manufacturing techniques. This dedication to innovation has enabled them to offer a wide range of assembly options, including single-sided, double-sided, and multilayer flexible PCBs, as well as rigid-flex PCBs that combine the benefits of both types of boards.In addition to their technical expertise, Flex PCB Assembly Manufacturer also prides itself on its customer-centric approach. The company works closely with clients to understand their specific requirements and provide tailored solutions that meet their unique needs. From prototype development to full-scale production runs, Flex PCB Assembly Manufacturer is dedicated to delivering high-quality, reliable assembly services on time and within budget.Flex PCB Assembly Manufacturer's state-of-the-art manufacturing facility is equipped with advanced equipment and technology to ensure the highest level of quality and precision. The company follows strict quality control processes and industry standards to guarantee the reliability and performance of their flexible PCB assemblies.Furthermore, Flex PCB Assembly Manufacturer is committed to sustainability and environmental responsibility in their manufacturing processes. The company adheres to stringent environmental regulations and sustainability practices to minimize their carbon footprint and reduce waste. This dedication to eco-friendly manufacturing has earned them recognition as a responsible and ethical electronics manufacturer.Looking ahead, Flex PCB Assembly Manufacturer is poised for continued growth and success in the electronics manufacturing industry. With a strong focus on innovation, quality, and customer satisfaction, the company is well-positioned to meet the evolving needs of their clients and adapt to the changing demands of the market.As the demand for flexible PCB assembly solutions continues to rise, Flex PCB Assembly Manufacturer is well-prepared to capitalize on this growth and remain at the forefront of the industry. With their industry-leading technology, commitment to excellence, and customer-oriented approach, Flex PCB Assembly Manufacturer is set to maintain its position as a top provider of flexible PCB assembly solutions for years to come.

Understanding the SMT Assembly Process in Factories

Smt Assembly Process Factories, a leading global electronics manufacturing company with a focus on high-quality, precision electronic components and assemblies, has continued to expand its operations and capabilities in response to the increasing demand for advanced electronics across various industries.The company has been at the forefront of providing innovative solutions for the assembly and manufacturing of surface mount technology (SMT) products. SMT is a key process in electronics manufacturing, as it allows for the creation of smaller, lighter, and more efficient electronic devices. With the increasing focus on miniaturization and the integration of advanced functionalities into electronic products, the demand for SMT assembly services has been on the rise.Smt Assembly Process Factories has established itself as a reliable and trusted partner for companies in need of high-quality SMT assembly services. The company offers a wide range of capabilities, including SMT assembly, through-hole assembly, box build assembly, and testing services. This comprehensive range of services has enabled Smt Assembly Process Factories to cater to the diverse needs of its customers, from small startups to large corporations.In addition to its advanced assembly capabilities, Smt Assembly Process Factories has also invested in state-of-the-art equipment and manufacturing facilities to ensure the highest level of precision and quality control. The company's commitment to quality is evident in its adherence to strict manufacturing standards and its implementation of industry-leading quality management systems.One of the key strengths of Smt Assembly Process Factories is its focus on innovation and continuous improvement. The company's dedicated team of engineers and technical experts are constantly exploring new technologies and processes to enhance the efficiency and capabilities of its assembly operations. This commitment to innovation has allowed Smt Assembly Process Factories to stay ahead of the competition and provide its customers with cutting-edge solutions.As part of its expansion efforts, Smt Assembly Process Factories has recently announced the opening of a new manufacturing facility in a strategic location to better serve its global customer base. This new facility is equipped with the latest SMT assembly equipment and is designed to meet the growing demand for high-volume production of electronic components and assemblies.Furthermore, Smt Assembly Process Factories has also expanded its workforce to include a team of highly skilled and experienced professionals who are dedicated to delivering exceptional service and support to customers. The company's workforce consists of individuals with diverse backgrounds and expertise, including engineers, technicians, quality control specialists, and customer service personnel.With its strong focus on quality, innovation, and customer satisfaction, Smt Assembly Process Factories is well-positioned to address the evolving needs of the electronics manufacturing industry. The company's commitment to delivering high-quality products and services has earned it a reputation as a preferred partner for businesses seeking reliable and cost-effective SMT assembly solutions.As the demand for advanced electronics continues to grow, Smt Assembly Process Factories remains committed to staying at the forefront of technological advancements and delivering value-added solutions to its customers. The company's dedication to excellence and its ability to adapt to the changing industry landscape make it a key player in the global electronics manufacturing sector.

China's New Energy Electronics Industry Surges Amid Growing Demand

China New Energy Electronics Set to Revolutionize the Market with Cutting-Edge Technologies China New Energy Electronics (CNEE) is poised to make a groundbreaking foray into the renewable energy market by introducing state-of-the-art technologies that will revolutionize the industry. With a vision to build a sustainable and green future, CNEE aims to spearhead the adoption of clean energy solutions on a global scale. CNEE, a leading player in the field of new energy electronics, has a diverse range of products and services under its portfolio. From solar panels and wind turbines to energy storage systems and electric vehicle (EV) charging infrastructure, CNEE is at the forefront of technological innovation in the renewable energy sector. With a strong emphasis on research and development, the company constantly pushes the boundaries of what is possible in the realm of clean energy. With environmental concerns and the need for sustainable energy becoming more prominent, CNEE's cutting-edge technologies are expected to play a crucial role in shaping the future of the industry. The company's commitment to providing efficient and reliable renewable energy solutions has been recognized by industry experts and customers alike. CNEE's solar panels employ the latest advancements in photovoltaic technology, resulting in high conversion rates and maximum energy generation. These panels are not only efficient but also aesthetically pleasing, allowing them to seamlessly blend into various architectural designs. Additionally, CNEE is actively exploring new materials and manufacturing processes to enhance the performance and durability of its solar panels. The company's wind turbines utilize advanced aerodynamic designs and intelligent control systems to optimize energy production. With an emphasis on minimizing noise and maximizing power output, CNEE's wind turbines are the pinnacle of efficiency and reliability. Furthermore, the company is actively developing offshore wind farms, harnessing the immense power of the ocean to generate clean and renewable energy. Energy storage systems are another area in which CNEE excels. The company's battery technologies offer high energy density, rapid charging capabilities, and extended cycle life. These energy storage systems can be seamlessly integrated with solar and wind power installations, effectively addressing the issue of intermittent energy production. As the demand for reliable energy storage solutions continues to grow, CNEE is well-positioned to meet the needs of the industry. CNEE is also committed to the widespread adoption of electric vehicles. The company's EV charging infrastructure provides fast and efficient charging options, making electric transportation more accessible and convenient. With a focus on intelligent charging solutions, CNEE aims to build a comprehensive network of EV charging stations to support the global transition to electric mobility. In addition to its impressive product portfolio, CNEE places great importance on sustainability and environmental stewardship. The company adheres to strict environmental standards in its manufacturing processes, ensuring minimal carbon footprint and waste generation. CNEE actively promotes recycling and reuse of materials to reduce the environmental impact associated with its products. As CNEE continues to innovate and expand its reach, the company is set to become a driving force in the renewable energy market. With a strong commitment to technological advancement and sustainability, CNEE aims to accelerate the transition to a greener and more sustainable future. By providing cutting-edge solutions in solar energy, wind power, energy storage, and EV charging, CNEE is revolutionizing the industry and cementing its position as a global leader in new energy electronics.

Optimized SEO Title: An In-Depth Look into Efficient PCB Assembly

Title: Cutting-Edge PCB Assembly Solutions Revolutionize the Electronics IndustryIntroduction:In today's rapidly evolving electronics industry, Printed Circuit Board (PCB) assembly is a critical process that ensures the seamless integration of components and the efficient functioning of electronic devices. One company, (delete brand name), has emerged as a leading provider of top-notch PCB assembly solutions, revolutionizing the industry with their cutting-edge technologies and unwavering commitment to quality. This article delves into the company's capabilities, their state-of-the-art facilities, and their significant contributions to the electronics manufacturing sector.1. A Legacy of Excellence:With over (delete number) years of industry experience, (delete brand name) has established itself as a trusted name in the field of PCB assembly. Their dedication to innovation, attention to detail, and customer-centric approach have enabled them to partner with some of the world's most renowned brands. The company's skilled workforce and robust supply chain management ensure that products are delivered on time and adhere to the strictest quality standards.2. State-of-the-Art Facilities:The core strength of (delete brand name) lies in their state-of-the-art manufacturing facilities equipped with advanced machinery and cutting-edge technologies. Their PCB assembly lines are designed to handle high volumes without compromising on precision and accuracy. The company's cleanroom environments minimize contamination risks, allowing for the assembly of highly sensitive electronic components. Additionally, (delete brand name) invests consistently in research and development, staying ahead of the curve in an ever-evolving market.3. Comprehensive Range of Services:(delete brand name) offers a comprehensive range of PCB assembly services, catering to industries such as consumer electronics, automotive, medical devices, aerospace, and telecommunications. From prototype assembly to full-scale production, the company meticulously meets the needs of each client. Their team of experts works closely with customers, providing design review, component sourcing, and cost-effective assembly solutions. This collaborative approach ensures that the end product meets both technical specifications and market demands.4. Emphasis on Quality Assurance:Quality is at the heart of (delete brand name)'s operations. The company follows stringent quality control measures at every stage of the PCB assembly process. Their highly trained quality assurance professionals conduct rigorous inspections and tests to ensure that each assembled board adheres to the highest standards. By employing advanced inspection techniques such as automated optical inspection (AOI) and X-ray testing, (delete brand name) guarantees product reliability and minimizes the risk of defects.5. Commitment to Environmentally Friendly Practices:In an era where environmental sustainability is paramount, (delete brand name) embeds environmentally friendly practices into their manufacturing processes. The company adheres to global standards and regulations like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment). By minimizing waste generation, optimizing energy consumption, and recycling materials, (delete brand name) reduces their carbon footprint and contributes to a greener future.6. Industry Recognition and Awards:The prowess of (delete brand name) in PCB assembly has been recognized through numerous industry accolades. Awards for operational excellence, innovation, and superior customer service highlight their commitment to delivering high-quality solutions. Such recognitions reinforce (delete brand name)'s position as an industry leader and further inspire their dedication to continuous improvement.Conclusion:(delete brand name) has emerged as a frontrunner in the electronics industry, providing top-notch PCB assembly solutions renowned for their quality, precision, and technological expertise. Through their state-of-the-art facilities, comprehensive services, and commitment to sustainability, the company continues to redefine industry standards. With an unwavering focus on excellence, (delete brand name) paves the way for technological advancements and contributes significantly to the growth and success of the electronics manufacturing sector.

Top Factories for Pin Through Hole Manufacturing: A Comprehensive Guide

Pin Through Hole Factories, a leading manufacturer of electronic components, has announced the expansion of its production facilities in order to meet the increasing demand for its products. With the global electronics market on the rise, the company is ramping up its manufacturing capabilities in order to ensure a steady supply of high-quality components to its customers. This expansion comes as part of Pin Through Hole Factories' commitment to providing innovative and reliable solutions to the electronics industry.The company, founded in 1995, has built a reputation for excellence in the production of pin through hole components. With a focus on quality, reliability, and customer satisfaction, Pin Through Hole Factories has become a trusted partner for electronic manufacturers worldwide. The company's dedication to continuous improvement and innovation has allowed it to stay ahead of the curve in a competitive industry. The expansion of its production facilities is a strategic move to position Pin Through Hole Factories for future growth and success. By increasing its manufacturing capacity, the company aims to better serve its customers and strengthen its position as a leading supplier of electronic components. The new facilities will feature state-of-the-art equipment and technology, allowing Pin Through Hole Factories to enhance its production capabilities and maintain its high standards of quality.In addition to the expansion of its production facilities, Pin Through Hole Factories is also investing in research and development to drive innovation in the design and manufacturing of electronic components. The company understands the importance of staying at the forefront of technological advancements in order to meet the evolving needs of its customers. By investing in R&D, Pin Through Hole Factories is committed to developing new and improved products that will set the standard for the industry.The expansion of Pin Through Hole Factories' production facilities is expected to create new job opportunities and contribute to the local economy. As the company grows, it will continue to support the community by providing employment and driving economic development. Pin Through Hole Factories understands the importance of giving back to the community and is dedicated to being a responsible corporate citizen.The expansion of Pin Through Hole Factories' production facilities is a testament to the company's commitment to meeting the growing demand for its products and providing exceptional service to its customers. By investing in state-of-the-art manufacturing capabilities and driving innovation through research and development, Pin Through Hole Factories is positioning itself for long-term success in the dynamic electronics industry.As the global electronics market continues to expand, Pin Through Hole Factories is poised to play a key role in supplying the components that power the latest technological innovations. With its dedication to quality, innovation, and customer satisfaction, Pin Through Hole Factories is well-positioned for continued growth and success in the years to come. The company's expansion of its production facilities is a clear indication of its commitment to meeting the needs of the electronics industry and its customers.

Top Suppliers of Mount Technology: A Comprehensive Guide

Mount Technology Suppliers, a leading provider of high-quality mounting solutions, is proud to announce its latest innovative product line designed to meet the evolving needs of its customers. With decades of experience in the industry, Mount Technology Suppliers has established itself as a trusted partner for businesses seeking reliable and cost-effective mounting solutions.The company offers a wide range of products, including wall mounts, desktop mounts, and ceiling mounts, designed to accommodate various types of technology, such as monitors, televisions, projectors, and more. Mount Technology Suppliers takes pride in its commitment to delivering superior products that are both durable and versatile, making it a top choice for businesses across various industries.One of the key factors that sets Mount Technology Suppliers apart from its competitors is its focus on innovation. The company continuously invests in research and development to ensure that its products are at the forefront of technological advancements. This dedication to innovation has led to the creation of a new line of mounting solutions that are tailored to meet the specific needs of modern businesses.The latest product line from Mount Technology Suppliers includes innovative features such as adjustable arms, cable management systems, and easy installation mechanisms. These features are designed to provide businesses with greater flexibility and convenience when it comes to mounting their technology. In addition, the new products are constructed from high-quality materials to ensure long-lasting reliability, even in demanding environments."We are excited to introduce our latest line of mounting solutions, which are the result of our ongoing commitment to innovation and customer satisfaction," said the spokesperson for Mount Technology Suppliers. "With these new products, we are confident that our customers will find the perfect mounting solutions to meet their unique requirements. Whether they need to mount a single monitor in a small office or a complex array of displays in a large commercial space, our products are designed to deliver exceptional performance."Mount Technology Suppliers understands that each business has its own set of requirements when it comes to mounting technology. To address this, the company offers customization options for its products, allowing customers to tailor their mounting solutions to suit their specific needs. Whether it's a unique mounting angle, a specialized mounting bracket, or a custom color finish, Mount Technology Suppliers can work with customers to create the perfect solution for their individual requirements.In addition to its commitment to innovation and customization, Mount Technology Suppliers is dedicated to providing exceptional customer service. The company's team of experts is available to offer guidance and support throughout the purchasing process, ensuring that customers are able to make informed decisions about their mounting solutions. Furthermore, Mount Technology Suppliers offers a comprehensive warranty and after-sales support to provide customers with peace of mind and long-term satisfaction.With the launch of its latest product line, Mount Technology Suppliers is poised to further solidify its position as a leader in the mounting solutions industry. The company's ongoing dedication to innovation, customization, and customer service sets it apart as a trusted partner for businesses seeking reliable and high-quality mounting solutions.As businesses continue to evolve and adapt to new technology, Mount Technology Suppliers remains committed to meeting their mounting needs with cutting-edge solutions designed to enhance efficiency and productivity. With its latest product line, the company is well-equipped to support the mounting requirements of businesses across various industries, delivering the reliability and performance that customers have come to expect from Mount Technology Suppliers.

Discover the Leading Source for High-Quality PCB Assembly Services

Title: One-Stop PCB Assembly Supplier Streamlines Manufacturing Process to Meet Industry DemandsIntroduction:In an era marked by unprecedented technological advancements, the demand for printed circuit boards (PCBs) has skyrocketed across various industries. To address this growing need, an industry-leading PCB assembly supplier has emerged as a pioneer in the field, offering comprehensive services to meet the electronic manufacturing requirements of companies worldwide. This news article will delve deep into the workings of this one-stop solution provider and explore how they have revolutionized the industry with their efficient manufacturing processes.Company Overview:With a vision to provide cutting-edge PCB assembly services, the company has quickly risen to prominence as a top-tier supplier in the industry. Renowned for its unwavering commitment to quality, innovation, and customer satisfaction, the company has amassed a loyal client base that spans multiple sectors, including automotive, aerospace, telecommunications, and consumer electronics.Streamlined Manufacturing Process:The success of this one-stop PCB assembly supplier can be primarily attributed to its streamlined manufacturing process, which ensures maximum efficiency without compromising on quality. By blending the latest technological advancements with a skilled workforce, the company has perfected the art of PCB manufacturing, meeting the stringent demands of the modern market.Advanced Facilities and Equipment:At the core of the company's operational excellence lies state-of-the-art facilities and cutting-edge equipment that aid in the flawless production of PCBs. The supplier has made substantial investments in upgrading their infrastructure, allowing them to handle projects of various complexities with ease. Equipped with advanced automated machinery, precision instruments, and high-quality materials, the company guarantees robust PCB assembly that meets international standards.Experienced Engineering Team:Behind the scenes, a team of highly experienced engineers play a crucial role in the success of the PCB assembly process. These experts possess a wealth of technical knowledge and expertise and work collaboratively with clients to design and develop PCBs that meet their specific requirements. With their meticulous attention to detail and focus on continuous improvement, the engineering team ensures that every PCB leaving the facility is of exceptional quality and reliability.Quality Assurance Measures:As reliability is a critical factor in the electronic manufacturing industry, the company has implemented rigorous quality assurance measures at every stage of the production process. From stringent material inspections to thorough testing and validation procedures, the supplier leaves no stone unturned to deliver faultless PCB assemblies. Furthermore, the company adheres to industry standards, certifications, and compliance regulations, imparting an added layer of trust among their clientele.Customization and Flexibility:Recognizing the diverse needs of their customers, the one-stop supplier offers a high degree of customization and flexibility in their services. With the capacity to handle both small-scale production runs and large-scale manufacturing projects, the company caters to organizations of all sizes. Through open communication channels, the company ensures that each client's unique specifications are met, fostering long-term partnerships based on trust and reliability.Global Reach and Timely Delivery:Operating on a global scale, the supplier has established a robust supply chain network that enables them to serve clients across continents. With strategically located and fully equipped manufacturing facilities, the company guarantees expedited delivery times without compromising quality. This global reach positions the one-stop PCB assembly supplier as a preferred choice for multinational companies seeking efficient and reliable manufacturing solutions.Conclusion:In an increasingly competitive market, this one-stop PCB assembly supplier has emerged as a game-changer, revolutionizing the manufacturing process and meeting the dynamic demands of various industries. With their technologically advanced facilities, skilled workforce, commitment to quality, and global reach, the company continues to build a strong reputation as a leader in the field. As the demand for PCB assemblies continues to grow, this supplier is well-positioned to play a pivotal role in shaping the electronic manufacturing landscape for years to come.

Pcb Assembly Services for Surface Mount Technology

The demand for electronic devices continues to grow, with consumers seeking smaller, more powerful, and more efficient products. To meet this demand, {} has announced the launch of their new surface mount PCB assembly, providing customers with advanced technology and high-quality assembly services.{} is a leading provider of electronic manufacturing services, offering a wide range of solutions for businesses in various industries. With a focus on innovation and customer satisfaction, {} has established itself as a trusted partner for companies seeking reliable and cost-effective electronic manufacturing solutions.The new surface mount PCB assembly is designed to meet the growing demand for compact and high-performance electronic devices. By utilizing state-of-the-art technology and advanced assembly techniques, {} is able to deliver PCBs that are smaller, lighter, and more efficient than traditional through-hole assembly methods.One of the key advantages of surface mount PCB assembly is its ability to accommodate increasingly complex designs. With the growing trend towards miniaturization, electronic devices are becoming smaller and more compact. Surface mount technology allows for the placement of components directly onto the surface of the PCB, making it possible to create smaller and more densely populated circuit boards without sacrificing performance.In addition to its size advantages, surface mount PCB assembly also offers improved performance and reliability. By eliminating the need for drilled holes and the use of leads, surface mount technology reduces the risk of mechanical failures and improves the overall electrical performance of the PCB. This makes it an ideal choice for applications that require high-speed and high-frequency operation.Furthermore, {}'s surface mount PCB assembly process is highly automated, allowing for increased efficiency and cost savings. By utilizing advanced pick-and-place machines and reflow soldering techniques, {} is able to achieve higher levels of precision and consistency in the assembly process. This results in higher-quality PCBs with fewer defects, ultimately saving time and money for their customers.With the launch of their new surface mount PCB assembly, {} is well-positioned to meet the evolving needs of the electronic manufacturing industry. By leveraging their expertise and state-of-the-art facilities, {} is able to provide customers with cutting-edge assembly solutions that are tailored to their specific requirements.As a leading provider of electronic manufacturing services, {} is committed to delivering exceptional value to their customers. Whether it's through their advanced assembly capabilities, innovative solutions, or dedicated customer support, {} strives to exceed expectations and establish long-lasting partnerships with their clients.In conclusion, the launch of {}'s new surface mount PCB assembly represents a significant milestone in the company's commitment to innovation and excellence. By offering advanced technology, high-quality assembly services, and exceptional value, {} is poised to continue serving as a trusted partner for businesses in need of reliable electronic manufacturing solutions.

Dip Plug-In Process Factory: Streamlining the Manufacturing Process for Optimal Results

Dip Plug-In Process Factory: Revolutionizing Manufacturing InnovationIn today's fast-paced world, the constant demand for innovation and efficiency has never been higher. Industries are constantly seeking new ways to streamline their manufacturing processes and develop cutting-edge technologies. In line with this trend, a groundbreaking Plug-In Process Factory has emerged, poised to transform the industry, thanks to its revolutionary manufacturing capabilities.The newly established Dip Plug-In Process Factory aims to redefine conventional manufacturing processes by implementing state-of-the-art technologies. This cutting-edge factory is backed by an experienced team of highly skilled engineers and technicians who strive to develop innovative manufacturing solutions for various industries.Dip Plug-In Process Factory prides itself on its ability to provide end-to-end manufacturing solutions tailored to each client's specific needs. From the initial design phase to production and final assembly, this factory offers a seamless process that ensures optimal manufacturing efficiency and top-notch quality.One of the key advantages that sets Dip Plug-In Process Factory apart from its competitors is its utilization of plug-in manufacturing processes. This innovative approach allows for greater flexibility and adaptability during the production stage. With plug-in technology, manufacturers can easily modify and customize their processes to accommodate changes in product design, market demand, or unexpected challenges.By implementing plug-in manufacturing processes, Dip Plug-In Process Factory helps businesses save valuable time and resources. The ability to make quick adjustments along the production line ensures that companies can respond swiftly to market trends and customer demands, gaining a competitive edge.Moreover, Dip Plug-In Process Factory understands the importance of sustainability in today's manufacturing landscape. The factory places a strong emphasis on eco-friendly practices, integrating environmentally conscious policies into their manufacturing processes. From energy-efficient machinery to waste reduction strategies, this factory strives to minimize its environmental impact while maximizing production capabilities.Dip Plug-In Process Factory's commitment to sustainability extends beyond their manufacturing practices. They actively engage in research and development to explore cleaner and more sustainable materials for use in production. By continuously seeking innovative solutions, Dip Plug-In Process Factory aims to contribute to a greener, more sustainable future for the manufacturing industry.Furthermore, the factory also offers comprehensive training and consulting services, providing clients with the tools and knowledge necessary to optimize their manufacturing processes. By partnering with Dip Plug-In Process Factory, businesses gain access to a wealth of expertise and insights into enhancing their production capabilities.With a proven track record of successful projects across diverse industries, Dip Plug-In Process Factory has established itself as a trusted partner for businesses aspiring to revolutionize their manufacturing processes. Through their unwavering commitment to innovation, sustainability, and efficiency, this factory has become a driving force behind the transformation of the manufacturing landscape.In conclusion, Dip Plug-In Process Factory is revolutionizing the manufacturing industry through its state-of-the-art plug-in manufacturing processes. With a focus on innovation, sustainability, and customization, this factory offers end-to-end manufacturing solutions tailored to each client's needs. By embracing plug-in technology, Dip Plug-In Process Factory enables businesses to adapt quickly to market changes and streamline their production processes. With a dedicated team of experts, a commitment to sustainability, and comprehensive training and consulting services, this factory is leading the way towards a more efficient and eco-friendly future for manufacturing.

Upgraded Testing Capabilities for PCBA: A Closer Look at the Latest Advancements

The demand for high-quality printed circuit board assembly (PCBA) testing capabilities is growing as the technology industry continues to advance. As a leader in the electronic manufacturing services industry, {} is proud to announce its enhanced PCBA testing capabilities, which will allow the company to provide even more reliable and efficient solutions to its customers.With the rise of smart devices, internet of things (IoT) technology, and other innovative applications, the need for reliable and high-performing PCBA testing has become more critical than ever. {} understands this need and has invested in state-of-the-art testing equipment and facilities to ensure that its customers receive only the highest quality products.The new PCBA testing capabilities at {} include advanced automated optical inspection (AOI), in-circuit testing (ICT), functional testing, and other methodologies to ensure that every aspect of the PCBA is thoroughly examined and meets the highest standards. These capabilities allow {} to identify and address any potential issues or defects in the PCBA early in the manufacturing process, which ultimately leads to more reliable and cost-effective products for its customers.In addition to the advanced testing equipment, {} also has a highly experienced and skilled team of engineers and technicians who are dedicated to ensuring the accuracy and reliability of the testing process. With their expertise, {} is able to offer customized testing solutions to meet the specific needs of each customer, further enhancing the quality and performance of the final product.The new PCBA testing capabilities at {} are also aligned with the company's commitment to sustainability and environmental responsibility. By conducting thorough testing and quality control measures, {} is able to minimize the risk of product failure and reduce the need for rework or replacement, ultimately contributing to a more efficient and sustainable manufacturing process.As a leading provider of electronic manufacturing services, {} is well-positioned to meet the growing demand for high-quality PCBA testing capabilities. With its advanced equipment, expert team, and dedication to excellence, {} is confident in its ability to deliver reliable and cost-effective solutions to its customers.{} is committed to continuously investing in its capabilities and resources to stay at the forefront of the industry and meet the evolving needs of its customers. The company's enhanced PCBA testing capabilities are a testament to this commitment, and {} looks forward to further strengthening its position as a trusted partner for electronic manufacturing services.In conclusion, the new PCBA testing capabilities at {} represent a significant advancement for the company and its customers. With state-of-the-art equipment, a skilled team, and a commitment to excellence, {} is well-equipped to provide reliable and efficient solutions to meet the evolving needs of the technology industry. Through its dedication to quality, sustainability, and customer satisfaction, {} is proud to offer enhanced PCBA testing capabilities that set a new standard for the industry.